Semi-automatic hole puncher for producing plastic dropping labels

A semi-automatic, punching machine technology, applied in metal processing and other directions, can solve problems such as easy to hurt hands, burrs, and affect the appearance of the product, and achieve the effect of improving efficiency, uniform strength, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

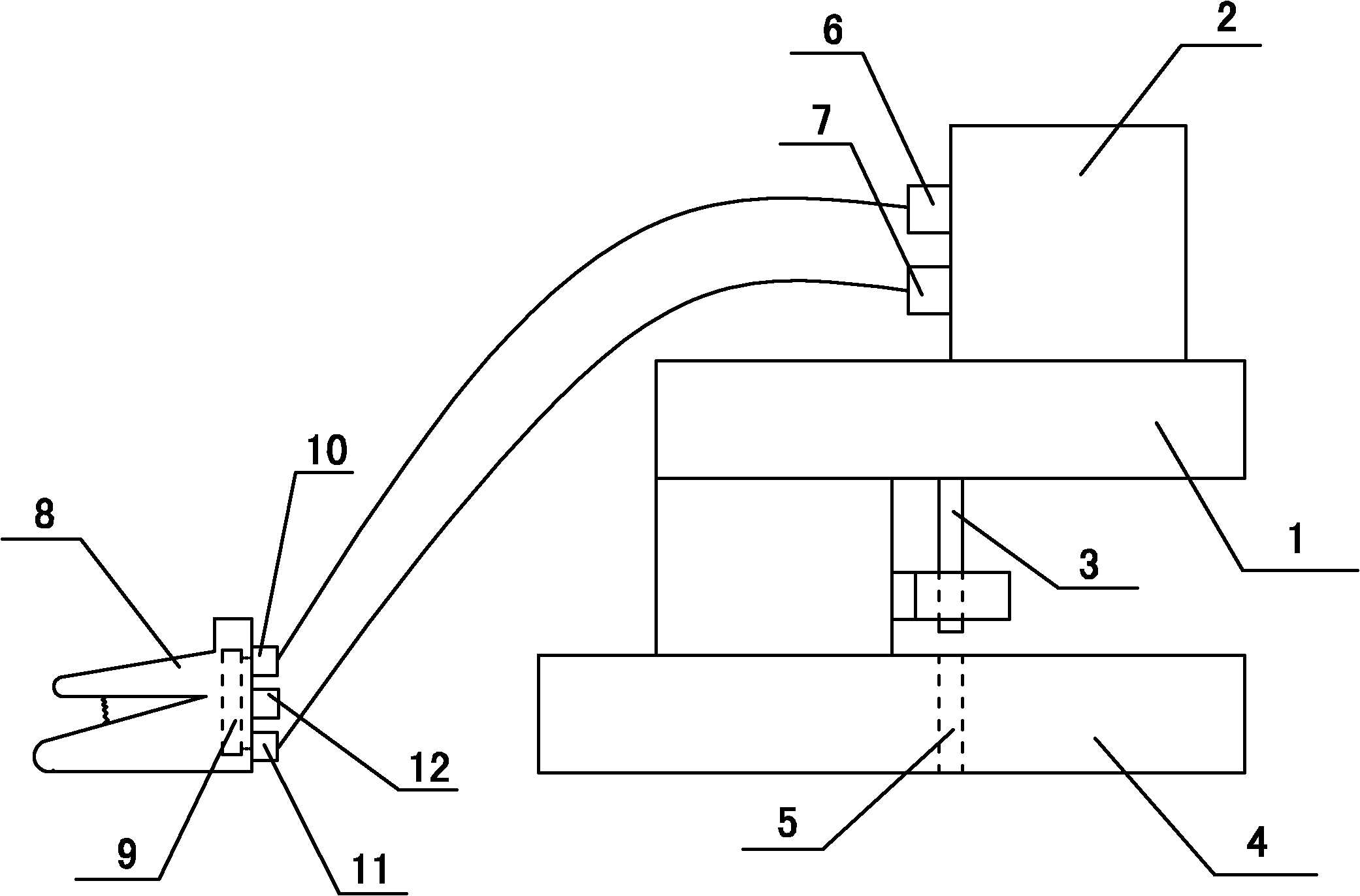

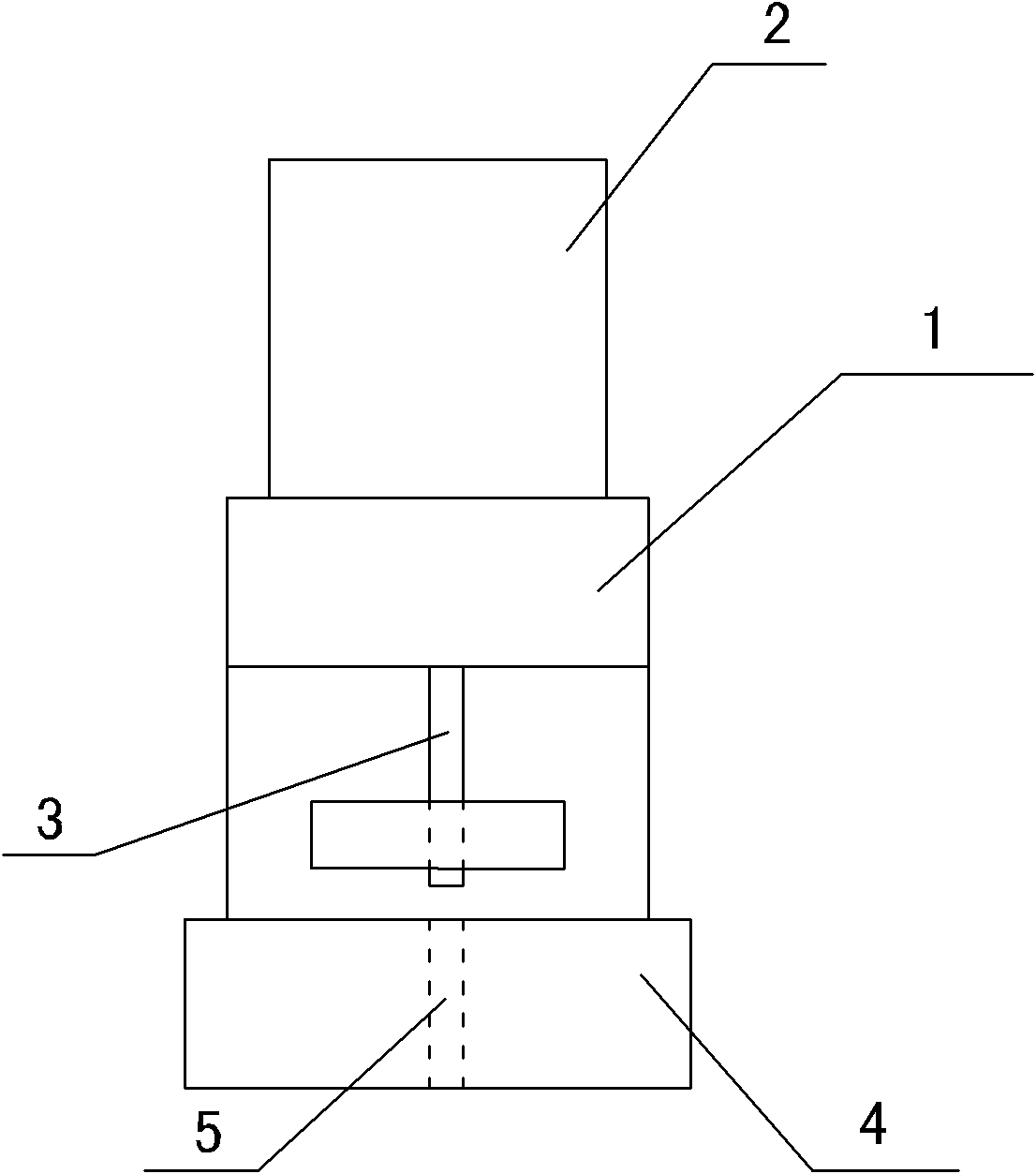

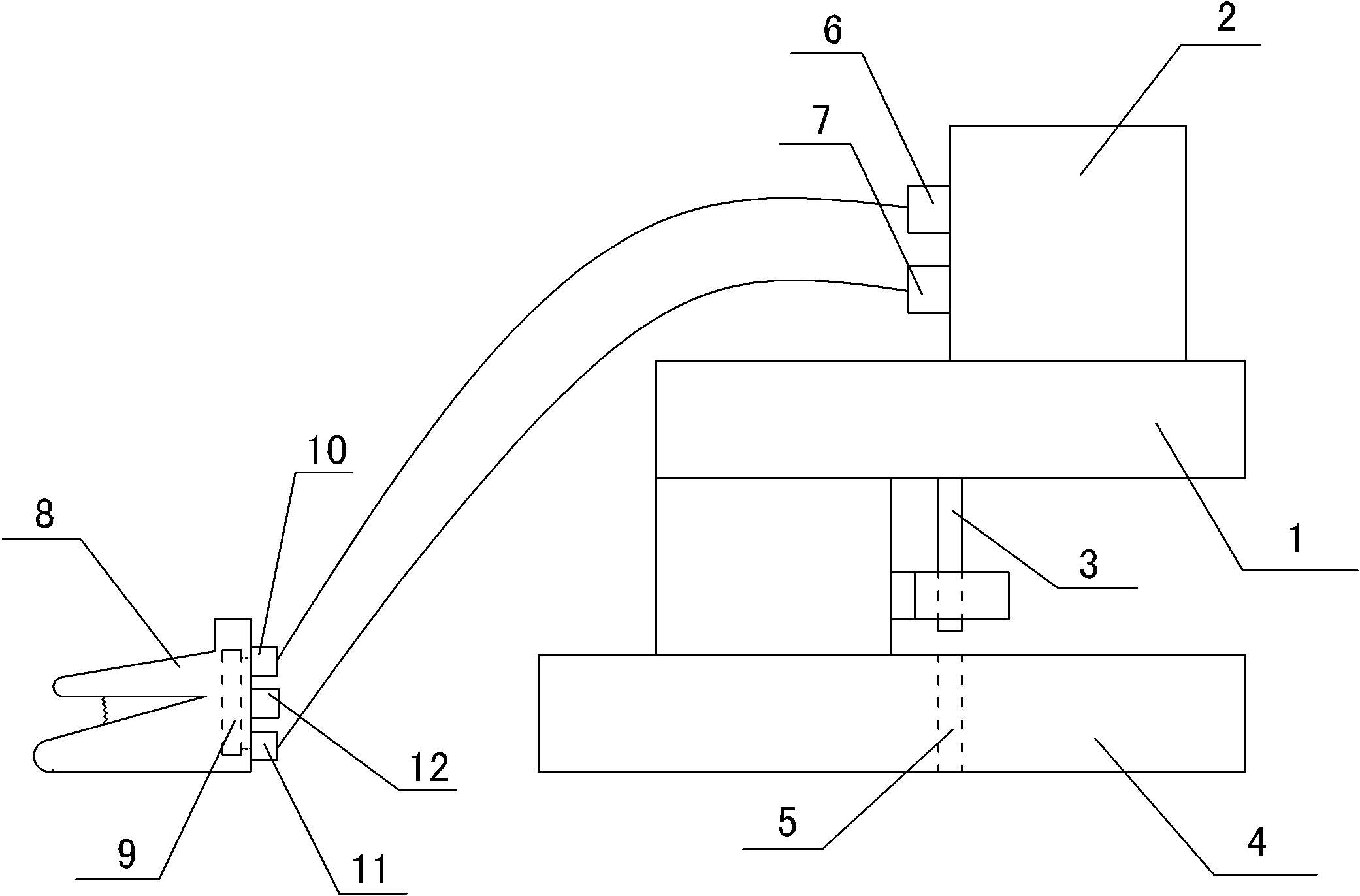

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0017] Such as figure 1 As shown, a cylinder 2 is installed on the frame body 1, a punching rod 3 is connected to the bottom of the cylinder 2, a guide hole 5 is correspondingly arranged on the base 4 below the punching rod 3, and a first inlet vacuum hole 6 and a first inlet vacuum hole 6 are provided on the cylinder 2. The second inlet vacuum hole 7, one side of the frame body 1 is provided with a foot switch 8, and a solenoid valve 9 is installed in the foot switch 8, and the first outlet vacuum hole 10, the second outlet vacuum hole 10, and the second outlet vacuum hole are also arranged on the foot switch 8. The hole 11 and the air path vacuum hole 12, the solenoid valve 9 are respectively connected with the first outlet vacuum hole 10 and the second outlet vacuum hole 11, the first inlet vacuum hole 6 is connected with the first outlet vacuum hole 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com