Self adhesive label and special film thereof

A label and dry glue technology, which is applied in decorative arts, instruments, layered products, etc., can solve the problems that thermal transfer labels cannot be used as commodity sealing labels, are easy to burr, and are not suitable for use, so as to promote environmental protection, low carbon, and paste Firmness and the effect of reducing the cost of labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

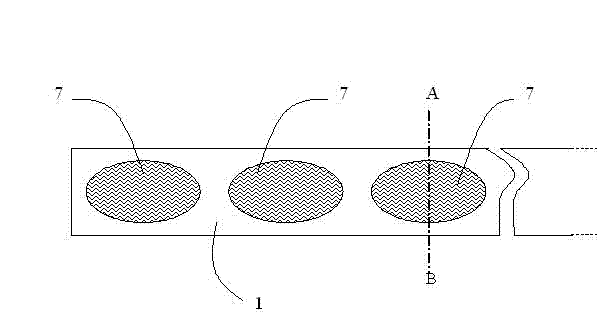

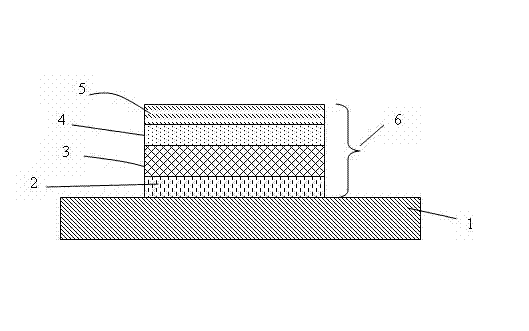

[0035] Embodiment one: if figure 1 , figure 2 As shown, referring to the formulation and process requirements of the prior art (Chinese patent CN200710022723.1 or Chinese patent CN02134698.4), a 32-micron thick, biaxially stretched high-temperature resistant PET transparent film roll is selected as the base tape layer (1) , coating a layer of 2-micron-thick separating agent on one side as a release layer (2) and a protective layer. A layer of 5 micron thick PE transparent film (3) is coated on the release layer (2), or a layer of 8 micron thick PET transparent film (3) is compounded. Then reverse print the necessary printed information layer (4) on it, and then print or coat the hot melt adhesive layer (5) on the printed information layer (4). Finally, after die-cutting and waste discharge, the label units (7) composed of the transfer layer (6) can be left on the baseband layer (1). In order to facilitate the automatic use of the thermal transfer machine, it can be cut int...

Embodiment 2

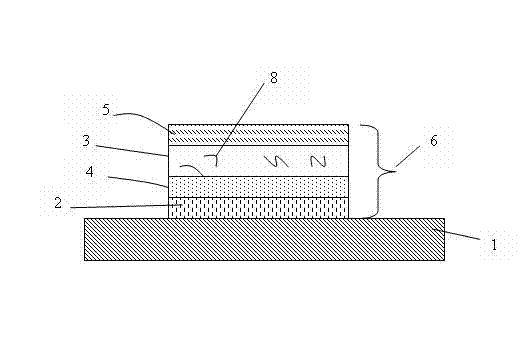

[0036] Embodiment two: if figure 1 , image 3 As shown, choose a 25 micron thick, biaxially stretched high temperature resistant PET transparent film roll material as the base belt layer (1), and coat a layer of 2 micron thick release agent on one side as the release layer (2) and protective layer .

[0037] Choose another 28g / m 2 The textured anti-counterfeiting paper (3) containing random fibers (8) has the necessary text, pattern information and identification serial number printed on the front; or, the necessary text, pattern information and identification serial number are reverse printed on the release layer (2) .

[0038] Laminate the textured anti-counterfeiting paper (3) prepared in the previous step on the release layer (2). And coat one layer of hot melt adhesive layer (5) on its back side. Each label unit (7) is scanned and photographed, and its photo is stored and filed in the database of the computer query system with its serial number as the file name.

[...

Embodiment 3

[0041] Embodiment three: as Figure 4 As shown, a 22-micron-thick, biaxially oriented high-temperature-resistant PET transparent film roll is selected as the base layer (1), and a layer of 3-micron-thick release agent is coated on one side as the release layer (2). A layer of PE transparent film (3) with a thickness of 6 microns is coated on the release layer (2), or a layer of PET transparent film (3) with a thickness of 8 microns is compounded. Then, it can be rolled and packaged to make the special film for dry glue label of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com