Dumpling processing machine and processing method thereof

A technology of processing machine and dumplings, which is applied in the field of food processing, can solve the problems of insatiability, poor taste of fillings, destruction of fillings, etc., and achieve the effects of improving production efficiency, reducing costs and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

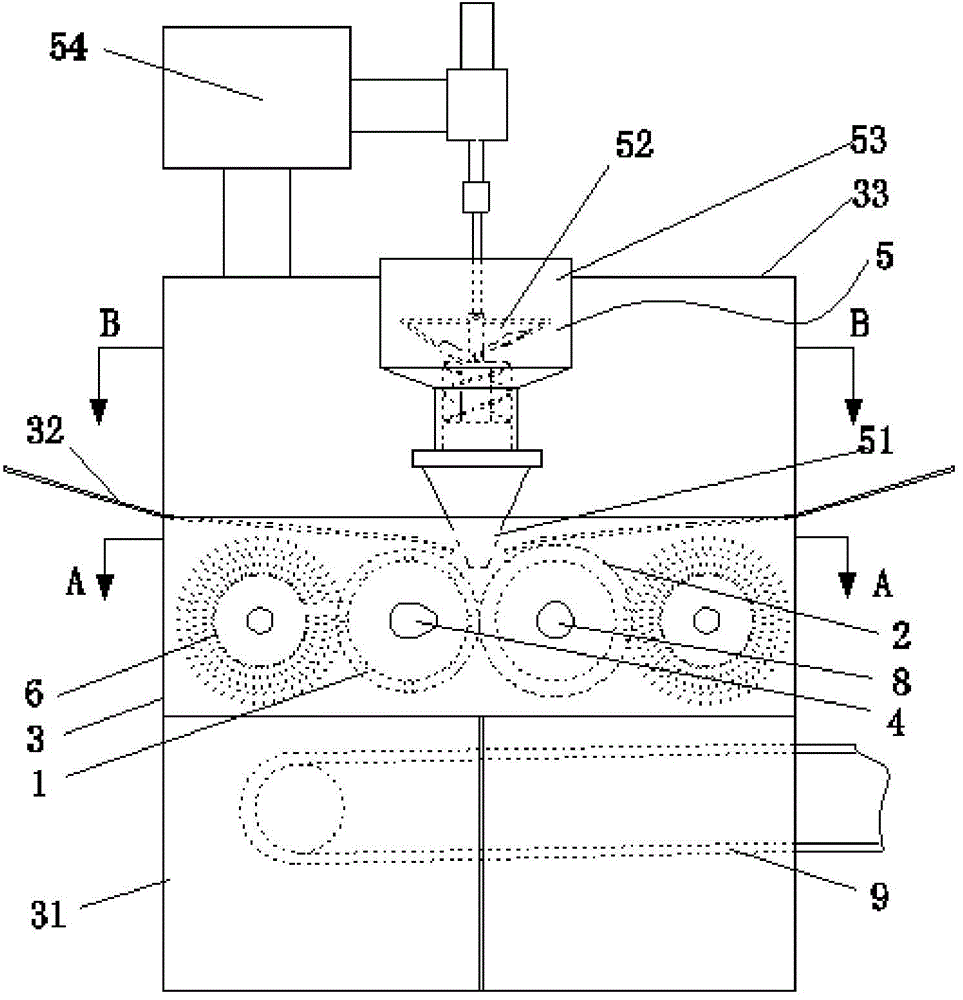

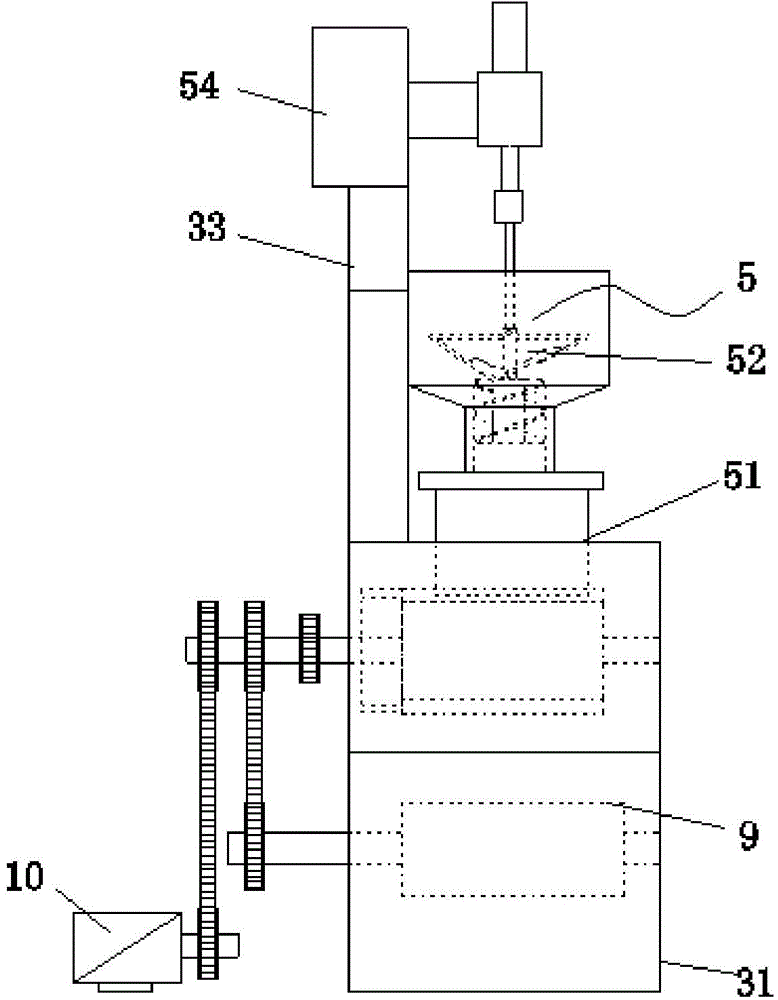

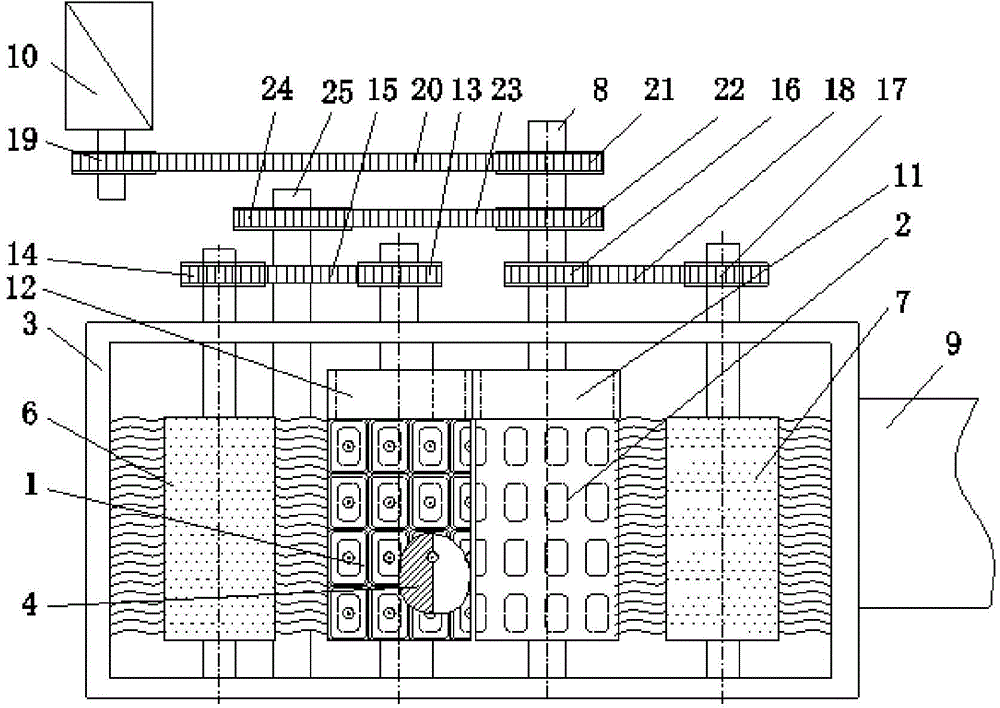

[0036] like figure 1 , figure 2Shown are the front view and the left side view of the dumpling processing machine of the present invention. As can be seen from the figure, the dumpling processing machine includes: a work frame 3, the bottom is supported by a bracket 31, and the left and right sides of the work frame 3 are respectively installed for supporting The support plate 32 of the dumpling skin is provided with a vertical support 33 on the rear side of the work frame 3; it is installed on the vertical support 33 above the work frame 3 and is used to stir the dumpling stuffing and output it downward. The conveying device 5, the discharge port 51 of which is vertically downward; the dumpling forming mold installed on the work frame 3 has the first roller mold 1 and the second drum mold 1 and the second roller mold for placing the dumpling skins respectively with their outer surfaces engaged and in opposite directions of rotation. Two roller molds 2, and the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com