Fossula type cam canister production method

A manufacturing method and technology of a cam barrel, applied in the field of lens barrels, can solve the problems of increased manufacturing cost, trouble, light leakage of zoom lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

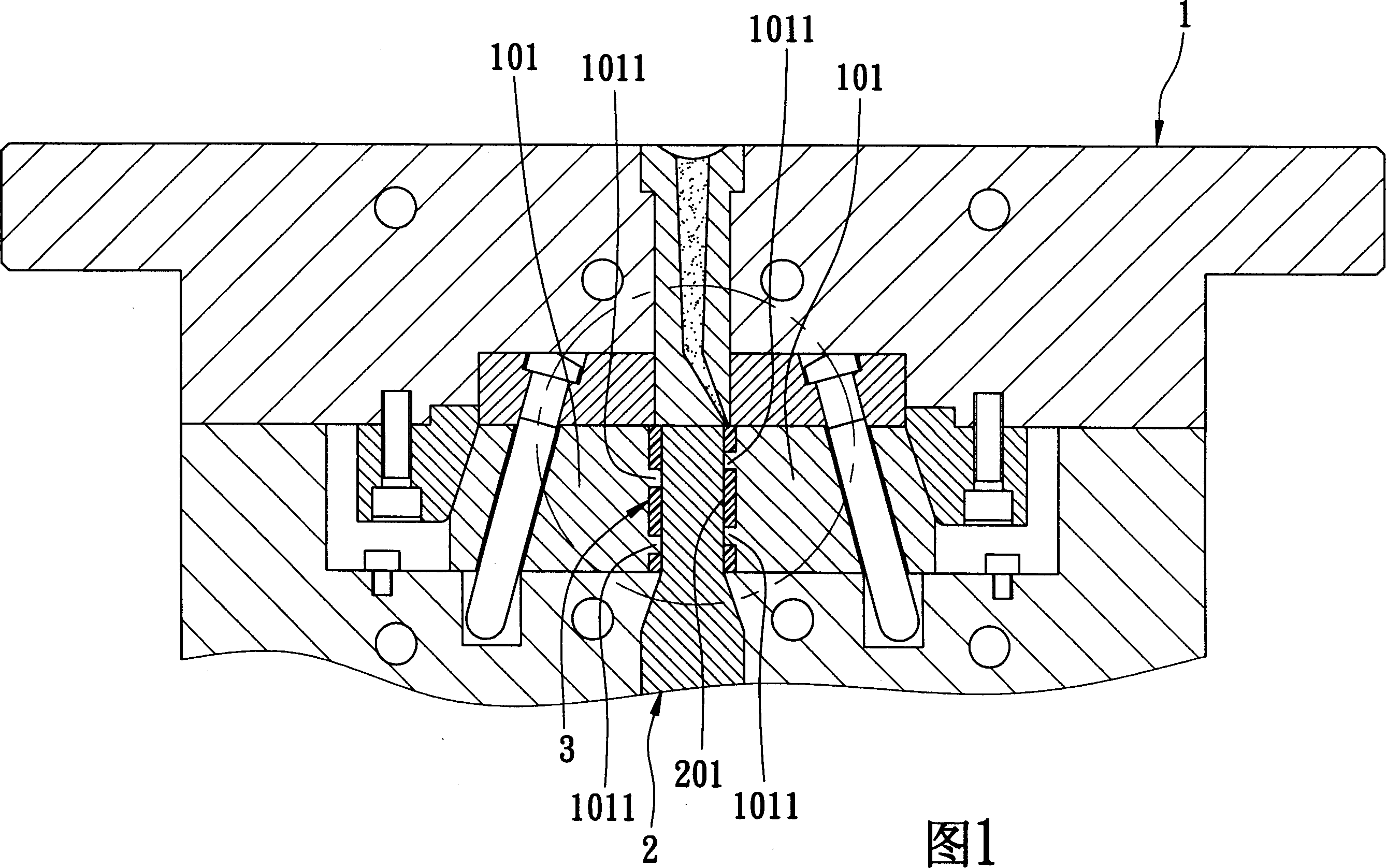

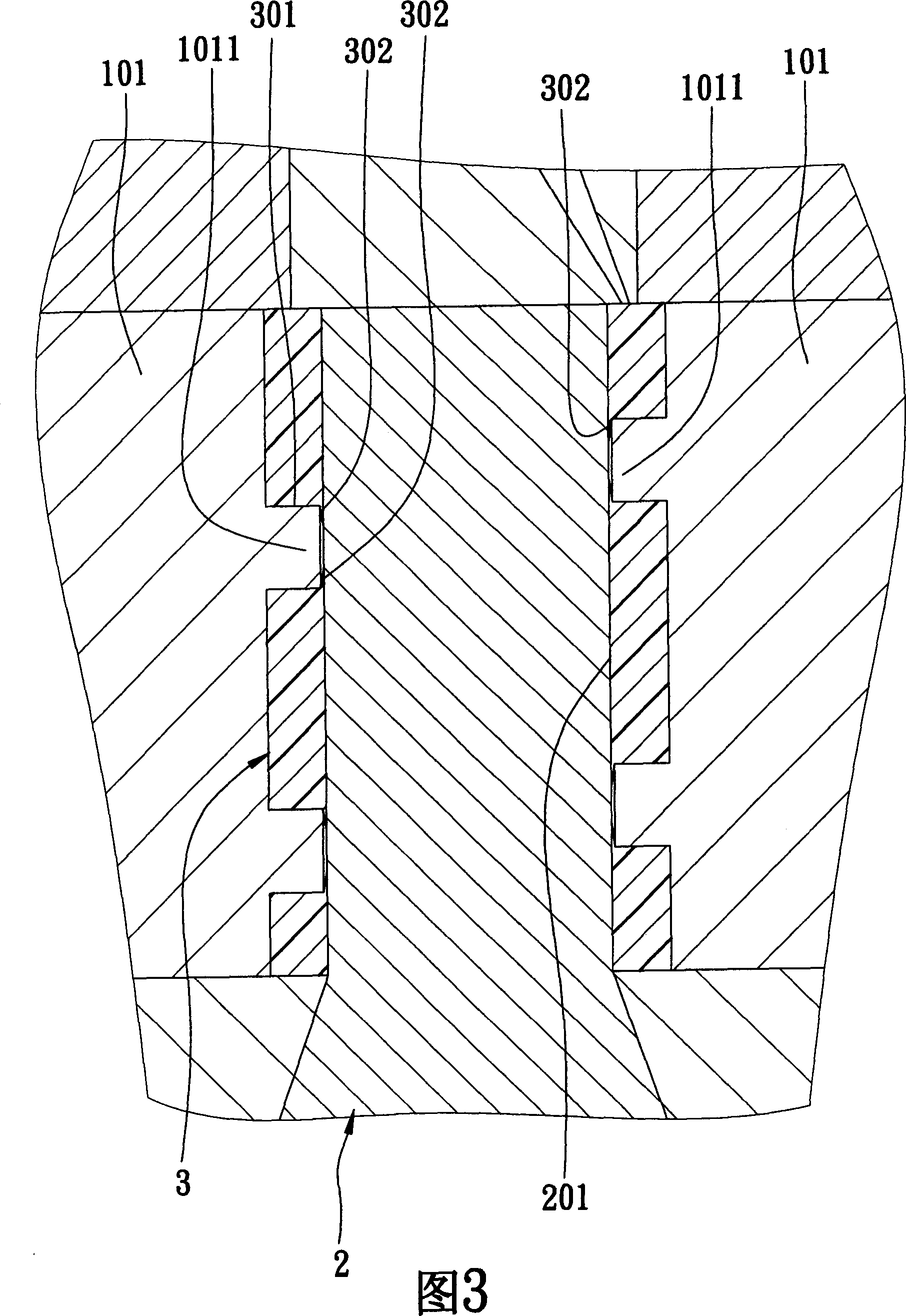

[0029] The aforementioned and other technical content, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

[0030] refer to Figure 4 , is a preferred embodiment of the manufacturing method of the inner groove type cam barrel of the present invention, and the manufacturing method comprises the following steps:

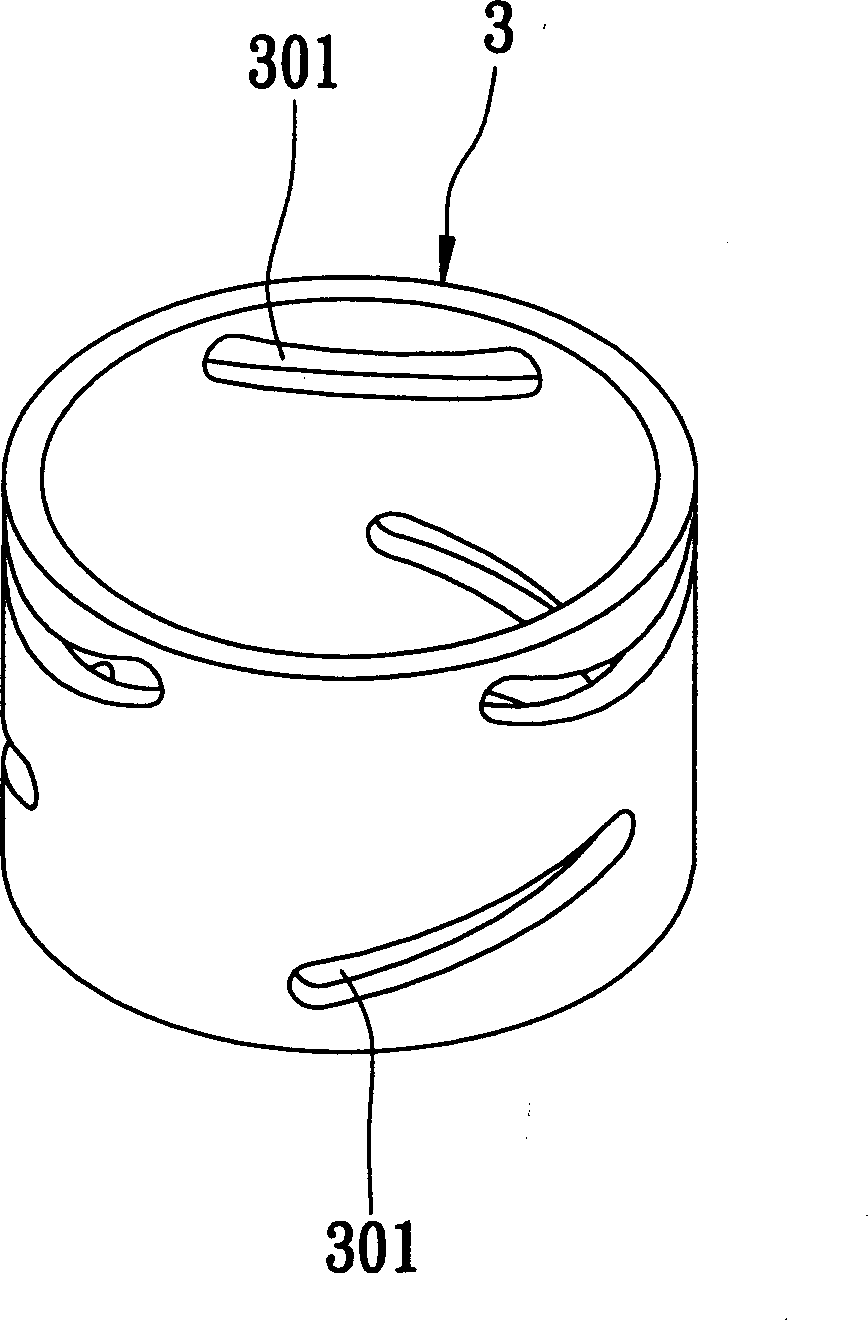

[0031] Step 1: Referring to Figures 5, 6 and 7, prepare a core molding die 10 with a core molding cavity 11 and three radially movable molding modules 12, each of which has a molding surface 121, and two cam grooves 122 respectively formed on the molding surface 121, and then a liquid fusible alloy material (fusible alloy) 20 is injected into the core mold forming cavity 11 to make the fusible alloy material 20 is molded in the core mold forming cavity 11 into a low-temperature alloy core mold having a pair of outer peripheral surfaces 31 corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com