External thermal insulation cement decoration panel provided with embedded punched metal strips at two side ends and assembling method thereof

A technology for punching metal plates and decorative panels, which is applied in covering/lining, construction, building construction, etc. It can solve the problems of heavy mortar filling and pointing workload, loose sealing of four sides of the mold, labor-intensive and time-consuming construction and assembly, etc. problems, to achieve the effect of saving construction labor costs, accurate shape and size, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

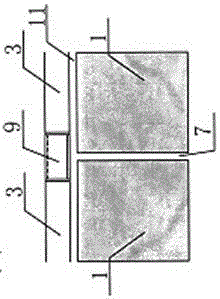

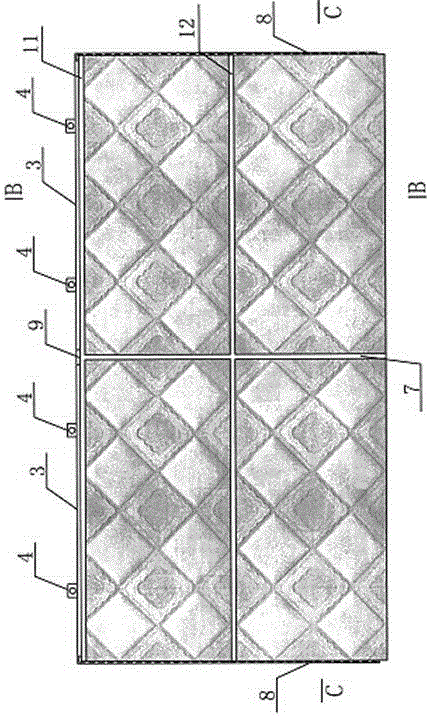

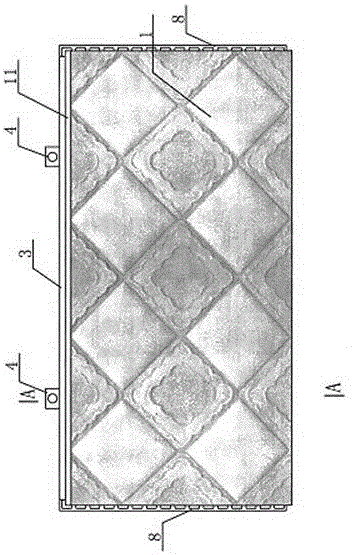

[0039] Such as Figure 1-Figure 13 The cement decorative panel used for the external thermal insulation of the exterior wall shown is equipped with a metal or non-metal mesh 10 inside, a three-dimensional decorative pattern 1 is prefabricated on the outer side, and a concave edge 11 of appropriate width and depth is provided on the upper edge; the inner side 2 is a plane , the upper end surface is provided with a long convex key 3, and metal pendants 4 are arranged at a certain distance, flanges 13 of appropriate height are arranged on the outer edges of the end surfaces of both sides, and punched metal laths 8 are pre-embedded, and punched metal laths 8 Appropriate width of the protruding side end surface; when the cement decorative panel is constructed and assembled, the horizontal seam method is: the lower end surface of the upper row of boards is superimposed on the end face of the next row of boards, and the full length of the upper end of the next row of boards is convex....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com