A method for inner hole polishing of metal parts formed by selective laser melting

A metal parts, laser melting technology, applied in the field of laser processing, can solve the problems of vibrating rod clamping, difficult positioning, prolonging the processing time of parts, and only one hole can be polished at a time, so as to shorten the polishing cycle and shorten the Manufacturing time and cost, effect of reducing polishing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

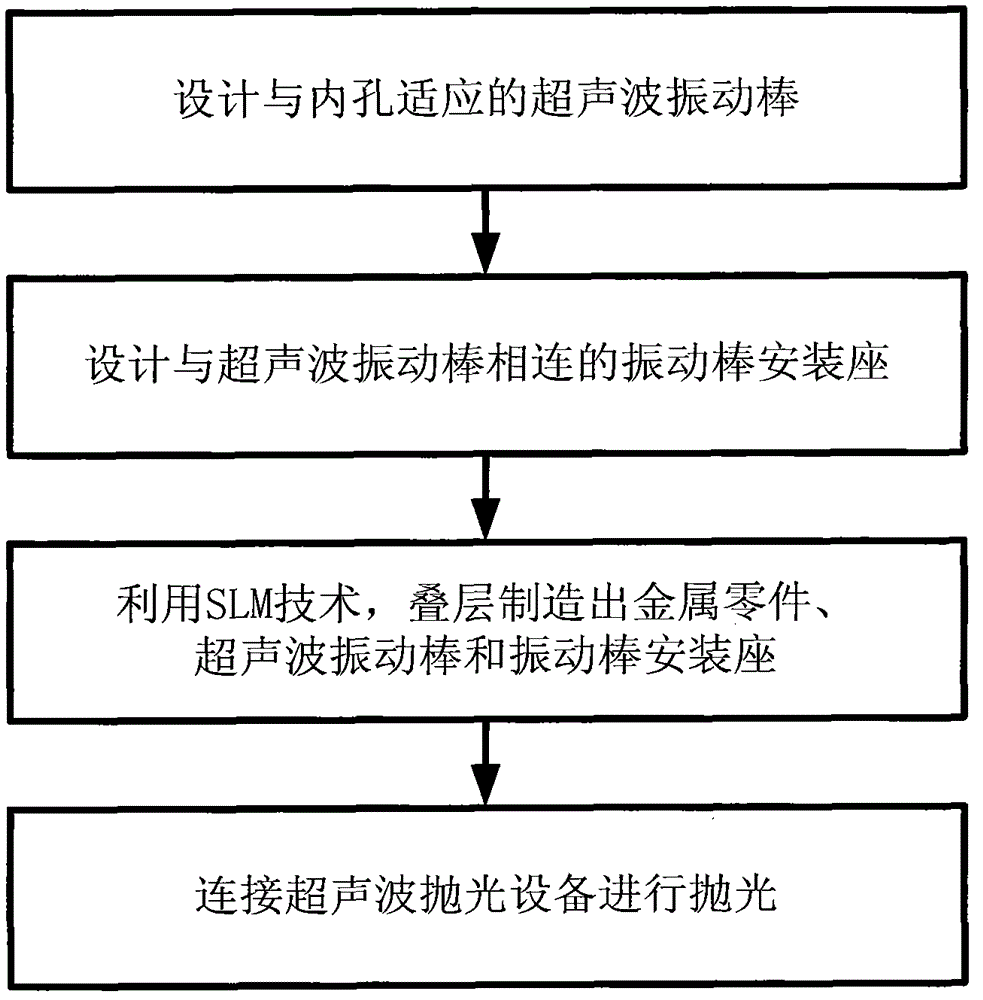

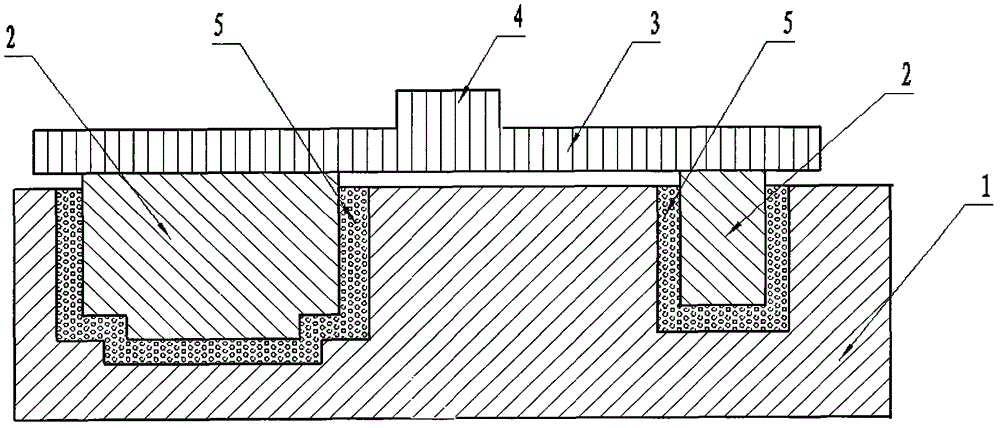

[0023] The invention provides a method for polishing inner holes of metal parts formed by selective laser melting, such as figure 1 , 2 shown, including the following steps:

[0024] (1) According to the CAD model of the metal part 1, design the ultrasonic vibrating rod 2 adapted to the inner hole on the metal part 1; the design method is the same as that of the existing ultrasonic vibrating rod, requiring the shape and size of the ultrasonic vibrating rod 2 It should be adapted to the shape and size of the inner hole of the metal part 1 for the ultrasonic polishing process.

[0025] The number of the ultrasonic vibrating rod 2 can be multiple, and its quantity and position distribution are determined according to the number and position distribution of the inner holes on the metal part 1, and only one ultrasonic vibrating rod can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com