Diameter-variable pitch-variable hard-plastic extruding rimer group of building material machine extruder

An extruder and variable pitch technology, applied in the field of brick and tile machinery manufacturing, can solve problems such as restricting the development of brick extruder technology, failing to meet technical requirements, reducing precision, etc., and achieving improved appearance quality, good versatility and interchangeability , the effect of reducing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

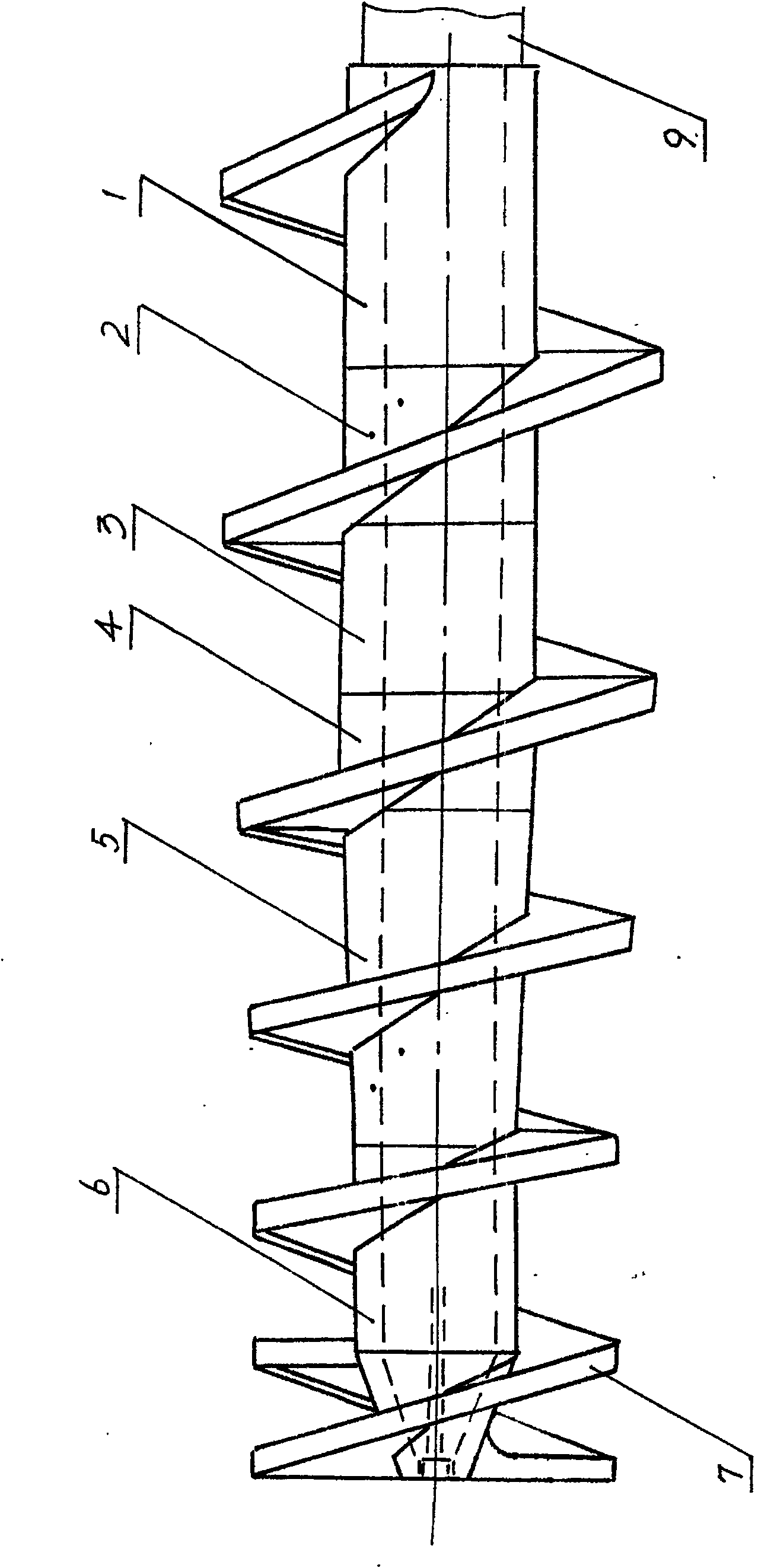

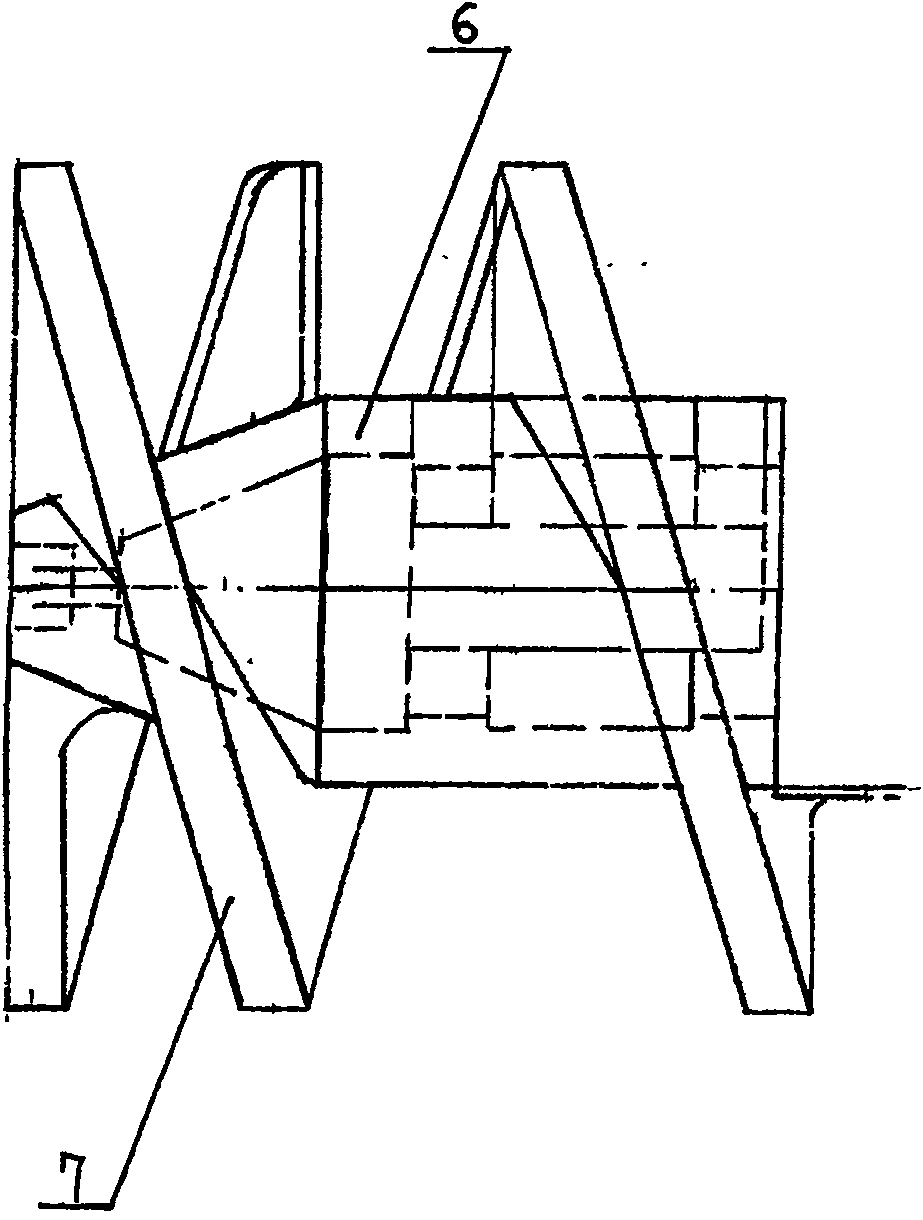

[0018] Figure 1-3 Specific embodiments of the invention are given.

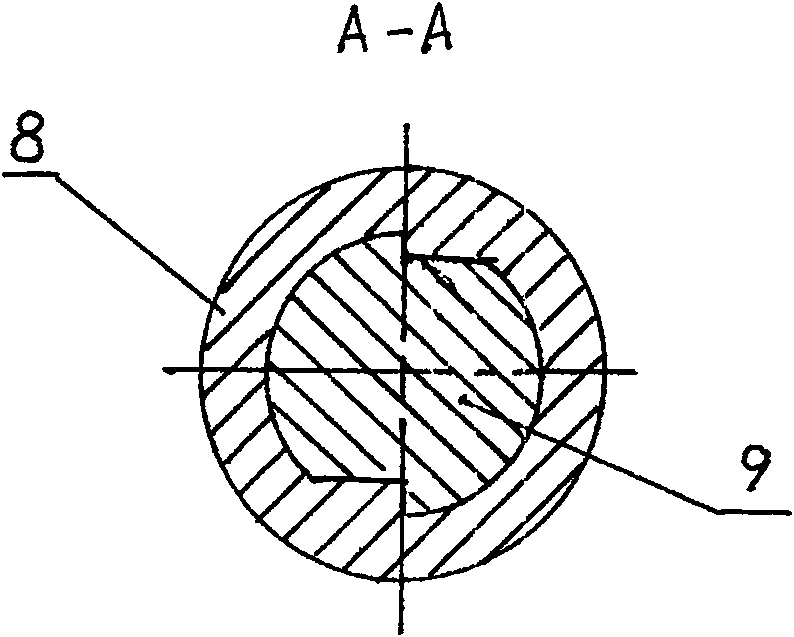

[0019] The spiral knife set is attached by figure 1 1, 2, 3, 4, 5, 6 are composed of 6 single pieces in total, the blade 7 of each reamer and the reamer tube 8 are cast as one, and the 6 reamers are set on the reamer shaft in a certain order 9, the torque is transmitted through the strong tangential concave-convex steps processed at the outer garden of the reamer shaft and the inner hole of the reamer tube, and the reamer shaft drives the reamer group to rotate together. After the spiral reamer 1-6 is installed, the outer diameter and screw moment of the screw gradually decrease along the extrusion direction of the mud material, forcing the rheological pressure of the mud material to gradually increase, and finally meet the molding requirements of the brick. The blades 7 of the last group of helical reamers 6 are double or multi-threaded, which are used to balance the extrusion pressure, overcome the helic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com