Intelligent wafer cutting machine

A technology for cutting machine tools and wafers, which is applied to work accessories, fine work devices, stone processing equipment, etc., can solve the problems of low production process efficiency, high electronic equipment prices, high costs, and improve cutting accuracy and automation. , Improve the success rate of cutting, optimize the effect of modules and designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In view of the above problems, the object of the present invention is to provide an intelligent wafer cutting machine tool, which uses an intelligent control module to control the machine tool to improve the cutting accuracy, and optimizes the module and design of the cutting machine tool at the same time, so that the cutting work efficiency is improved and the degree of automation is good. , to achieve intelligent processing work.

[0021] In order to achieve the above object, the present invention adopts the following technical solutions

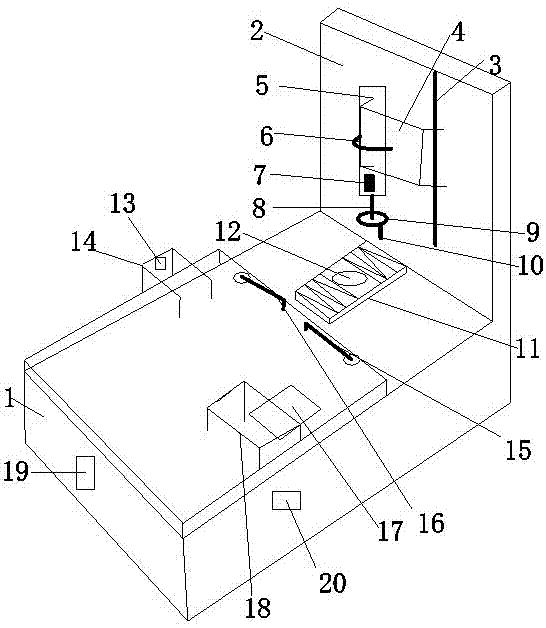

[0022] An intelligent wafer cutting machine tool, which includes a lathe body 1, a cutting frame 2, a slide rail 3, a lifting frame 4, a cutting arm 5, a fixing member 6, a motor 7, a transmission shaft 8, a wheel 9, a cutting tool 10, Workbench 11 , tray 12 , fan 13 , cleaning chamber 14 , first robot arm 15 , second robot arm 16 , storage table 17 , warehouse 18 , operating table 19 , and control module 20 .

[0023] One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com