Automatic cutting machine with vision alignment function, and control method thereof

A visual alignment and cutting machine technology, which is applied in shoemaking machinery, clothing, metal processing, etc., can solve the problems of pattern outline damage, high labor cost, and low cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

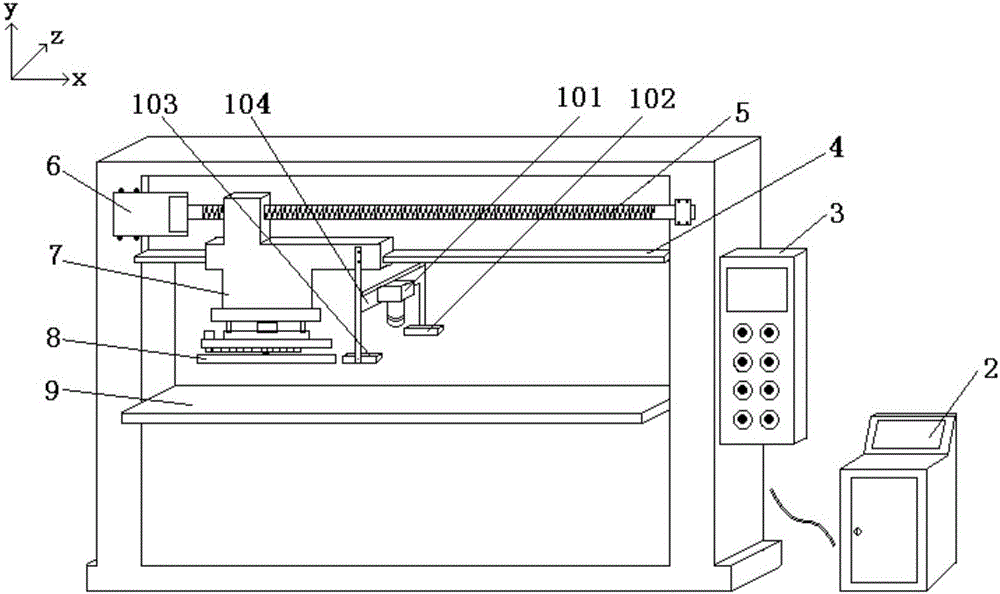

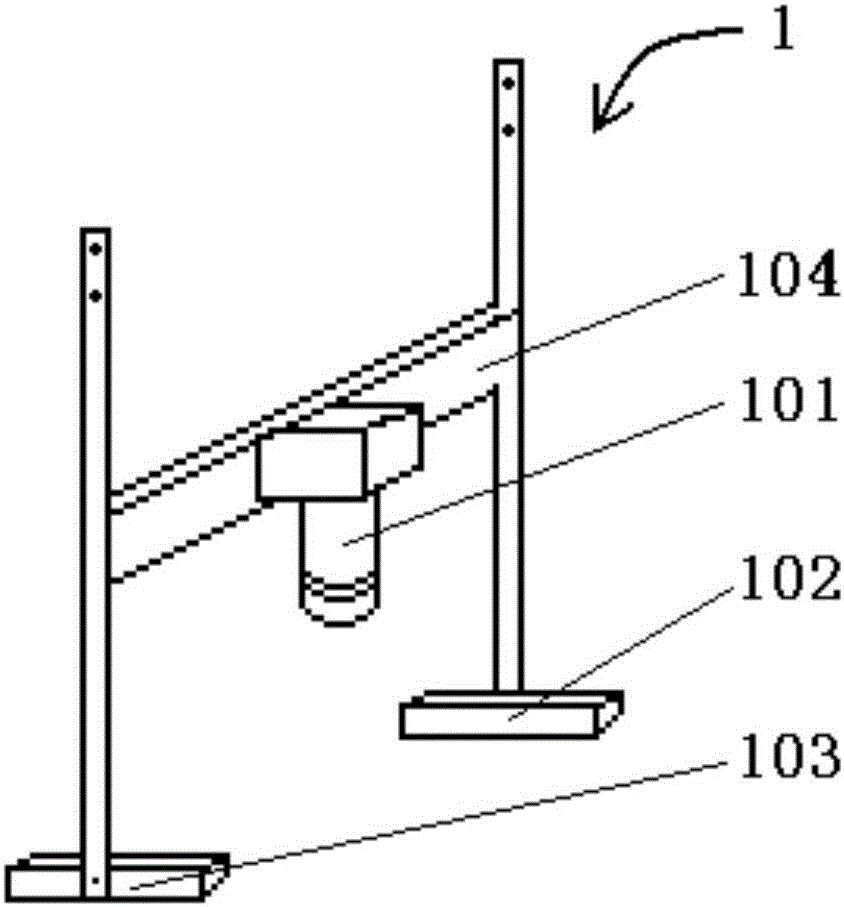

[0033] In the following, the application of the visual alignment automatic cutting machine of the present invention in the field of shoemaking will be further described in conjunction with the accompanying drawings.

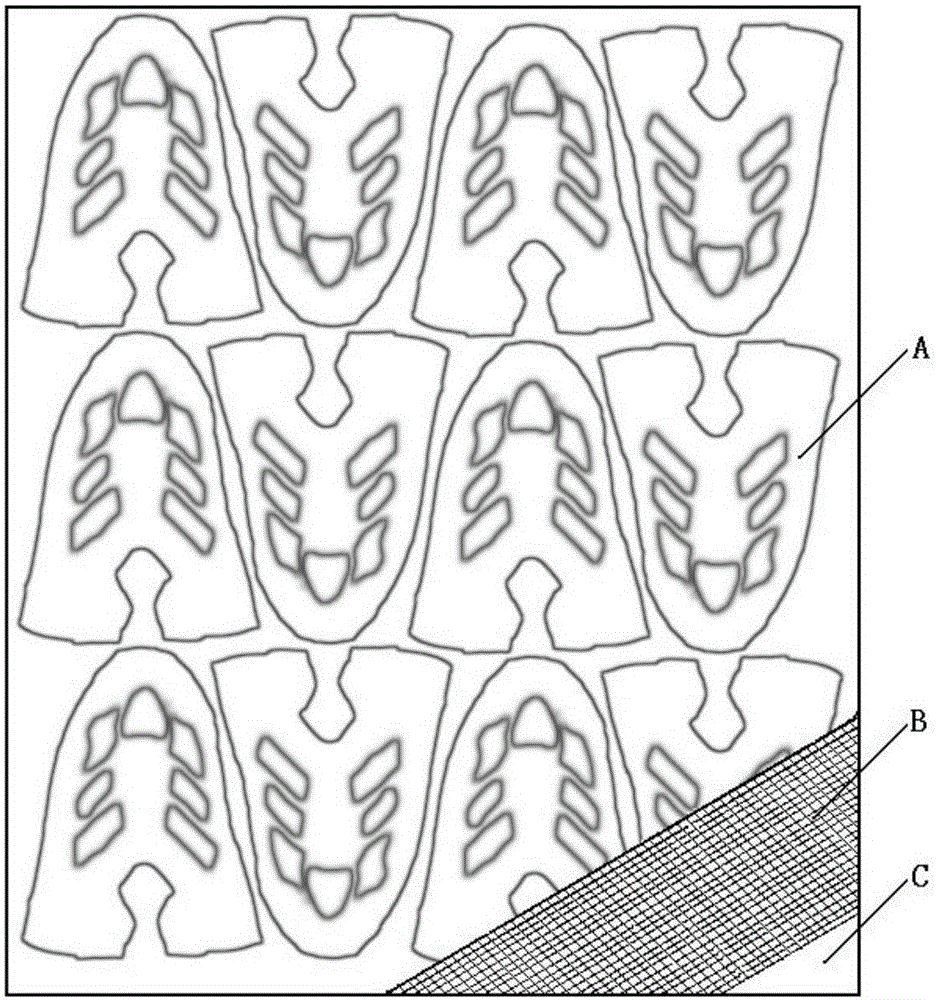

[0034] About the novel vamp material mentioned in the background technology such as figure 1 As shown, it is a new type of multi-layer composite belt outline pattern fabric. When cutting this material, it is required that the knife die will completely match the outer contour line printed on the surface layer A of the fabric pattern. Because the contours printed on the surface may be inconsistent in length, length and angle, it is impossible to cut by setting a fixed distance between die stepping and a fixed angle of die disc rotation, and each cutting requires precise alignment. This kind of material is not limited to the three layers shown in the figure, but may also be two or more layers, because the surface is printed with the commonality of the contour of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com