Food residue disposal

A technology of catering waste and processing machine, which is applied in the direction of grain processing, press, material forming press, etc. It can solve the problems of polluting the environment, catering waste cannot be processed in time, and oil and water cannot be separated, so as to reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

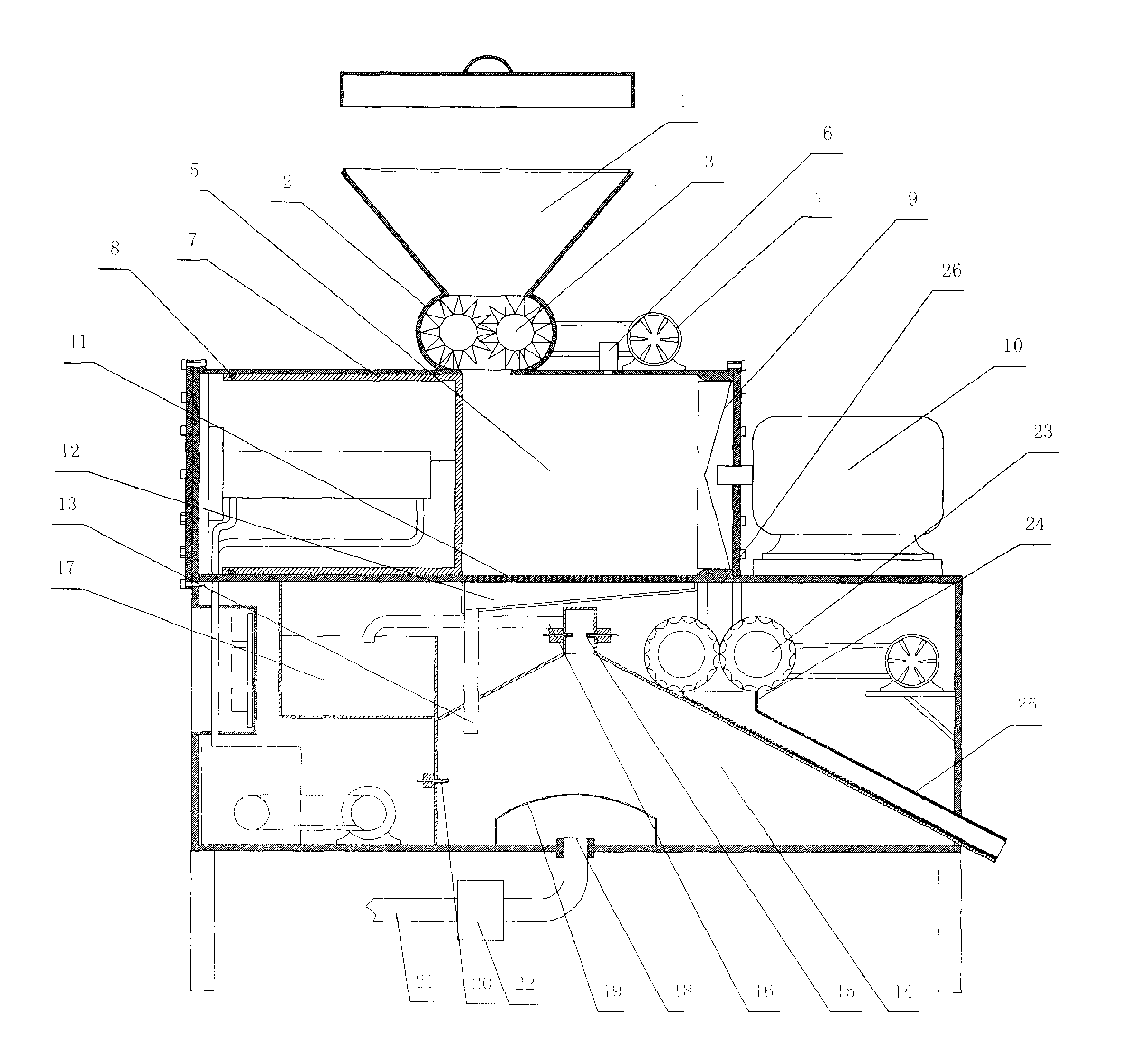

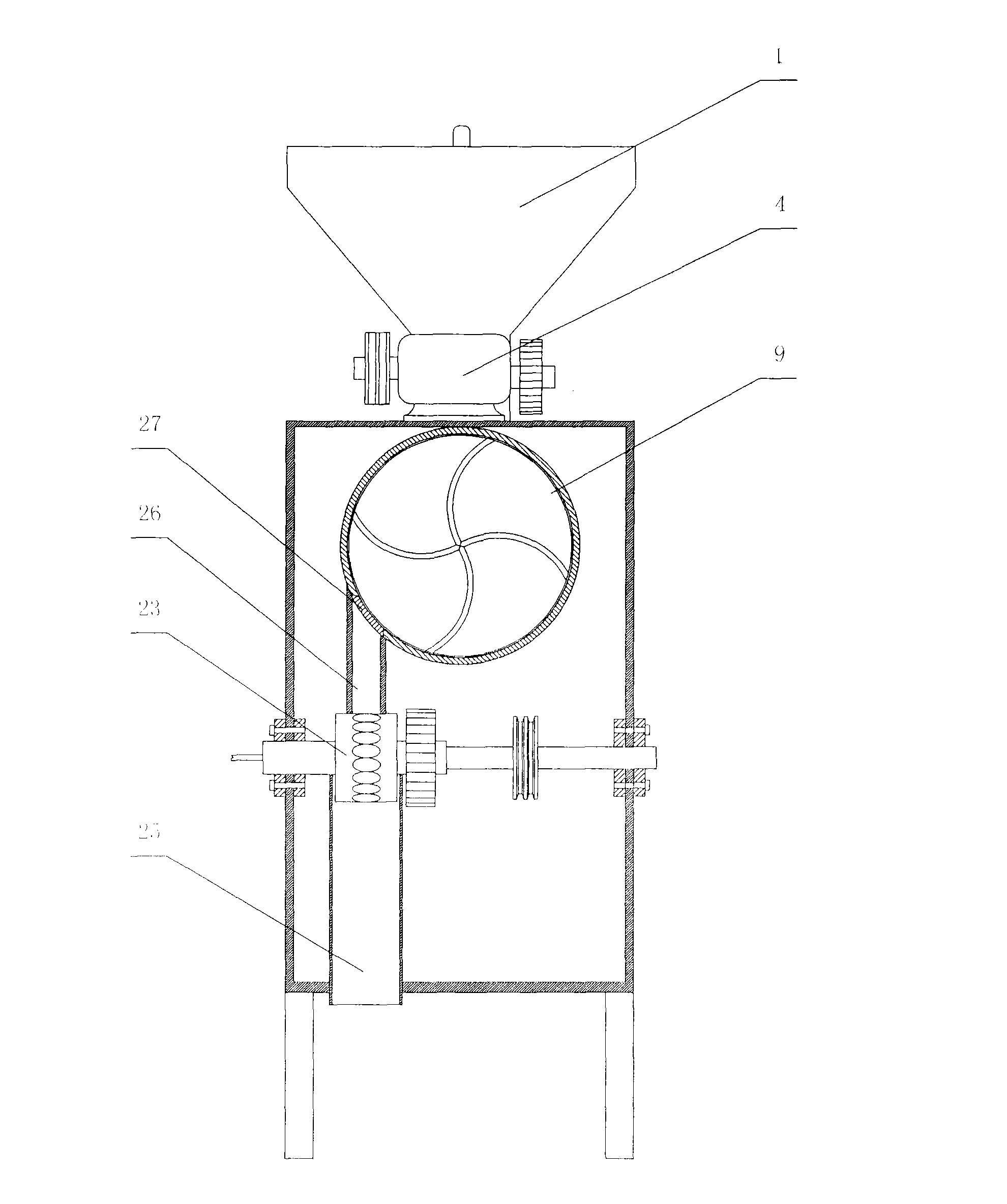

[0021]Implementation case: a food waste processing machine, including a frame, on which a crushing device 2, a squeezing device 5, a solid forming device, and an oil-water separation device 14 are arranged; the upper end of the crushing device 2 is provided with a feed hopper 1, and the crushing device 2 is provided with a pair of rolling shaft devices 3 that rotate relatively inwardly. One end of the rolling shaft devices 3 is respectively provided with gears that cooperate with each other, and the other end of one of the rolling shaft devices is connected to a driving device 4. There are pointed conical teeth intersecting each other on the top respectively. When the food waste reaches a certain position in the feeding hopper 1 and the sensor installed in the feeding hopper 1 senses it, the driving device 4 starts to move and drives the crushing device 2 to work. , the tapered teeth set on the rolling shaft body rotate inward, and the food waste in the feeding hopper 1 is brou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com