Prefabricated beam-column joint and construction method thereof

A technology of beam-column joints and construction methods, which is applied in the direction of architecture and building construction, can solve the problems of heavy construction workload, collisions, and uneconomical problems, and achieve the goals of simplifying construction procedures, increasing construction speed, and improving connection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

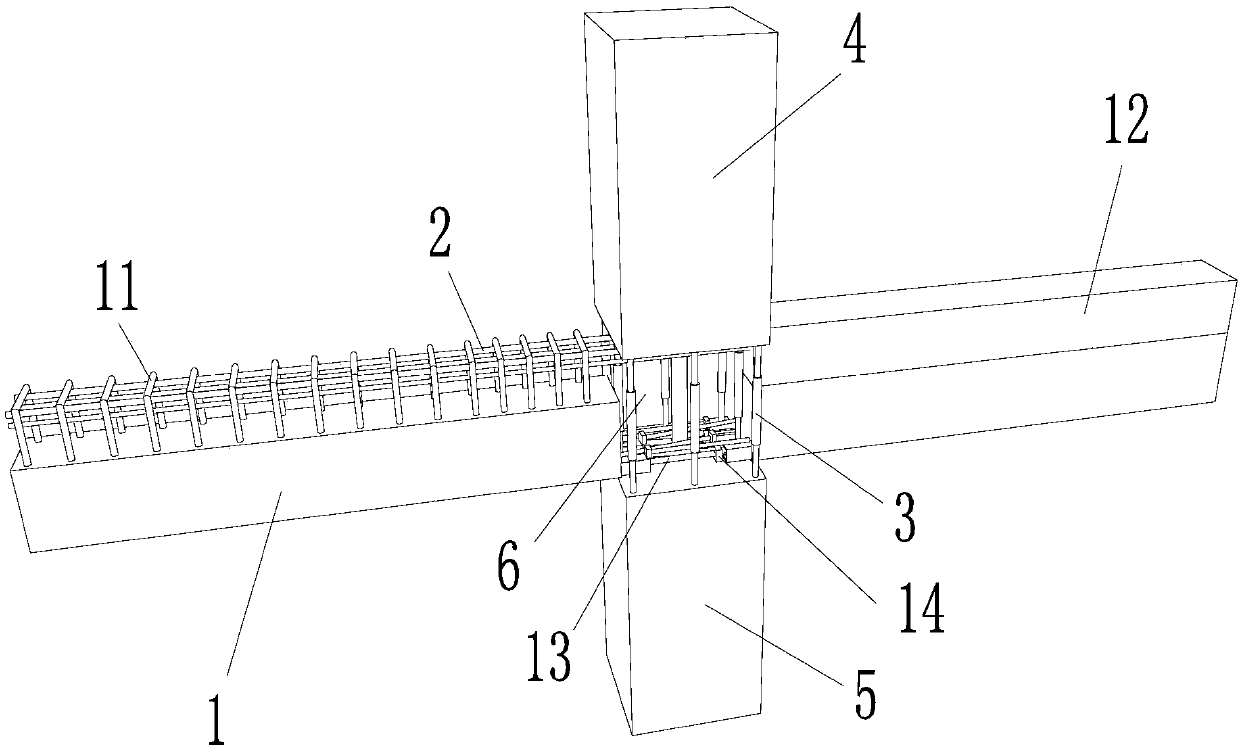

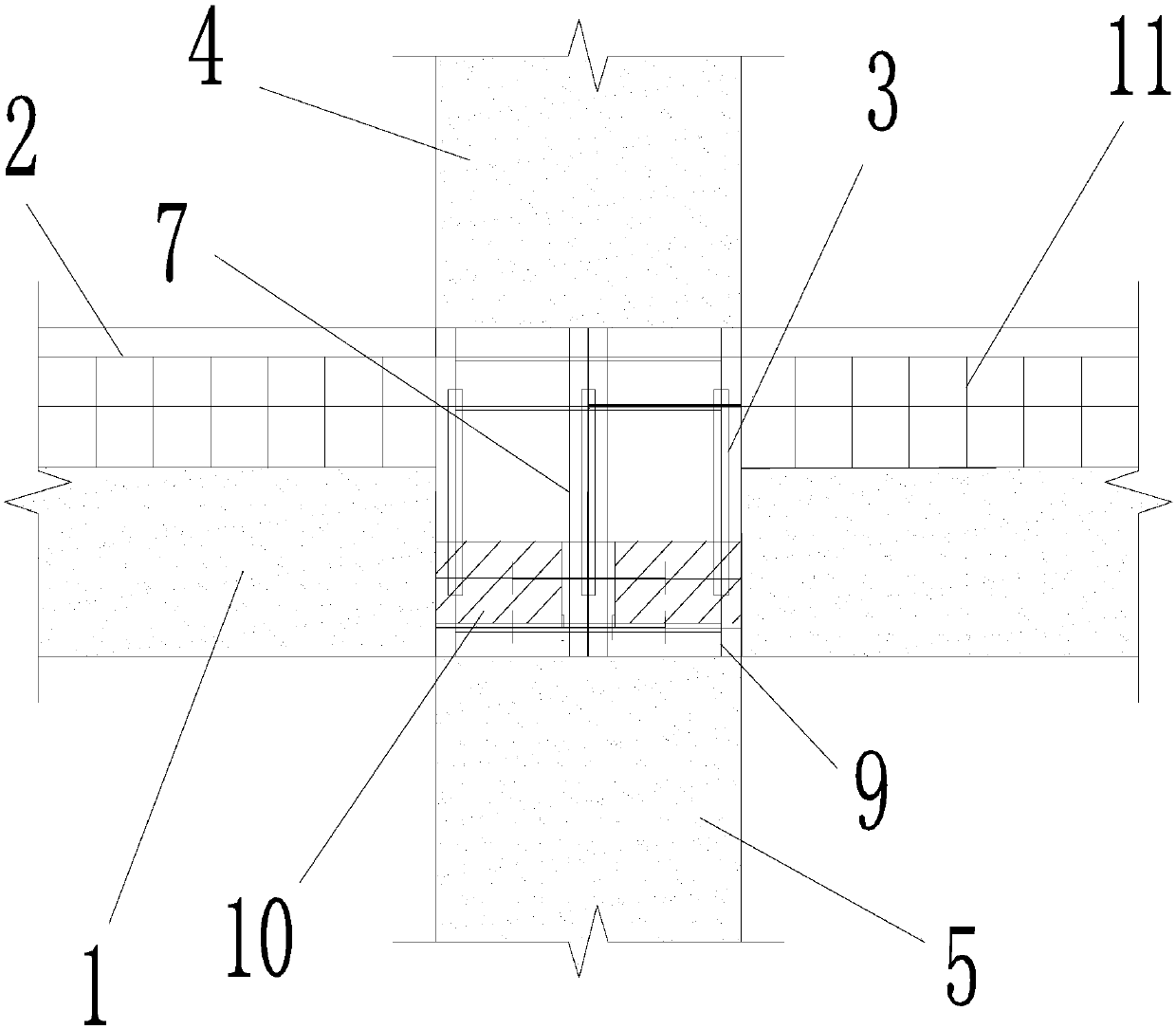

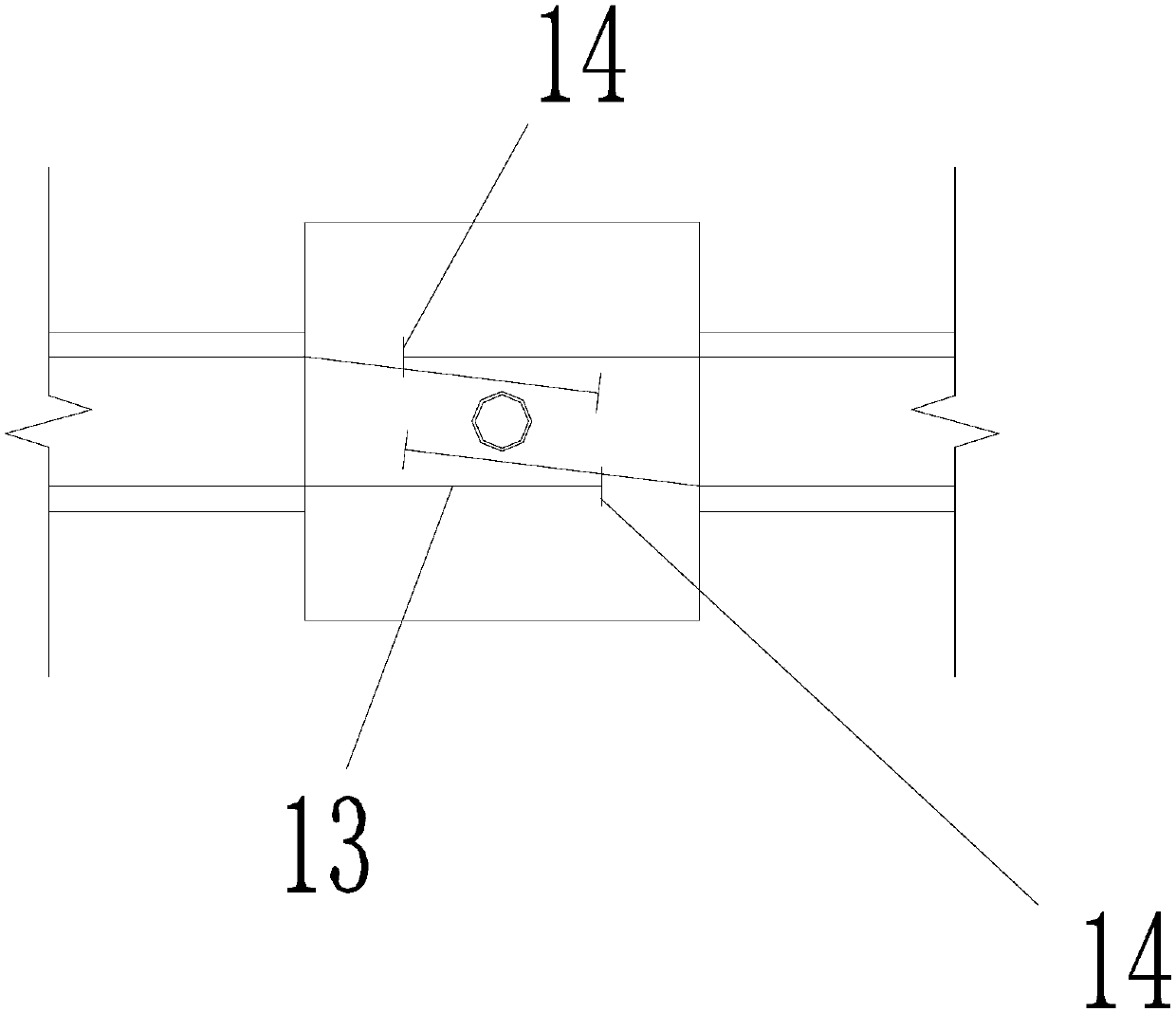

[0047] A prefabricated beam-column joint, including a prefabricated beam, a prefabricated column, a beam connecting bar and a joint reinforcement sleeve. The prefabricated column includes a prefabricated upper column and a prefabricated lower column. Between the upper column and the prefabricated lower column; a node area is formed between the prefabricated upper column, the prefabricated lower column and two sections of prefabricated beams, and the node area is filled with concrete to form the node section;

[0048] The prefabricated upper column is provided with pre-embedded steel pipes along the length direction of the prefabricated upper column and the reserved longitudinal reinforcement of the upper column along the length direction of the prefabricated upper column. Exit the bottom surface of the prefabricated upper column and enter the node segment;

[0049] The prefabricated lower column is provided with the reserved longitudinal reinforcement of the lower column along...

Embodiment 2

[0057] A construction method for prefabricated beam-column joints, comprising the following steps:

[0058] Fabrication of prefabricated beams: bury embedded channel steel at the bottom of the prefabricated beams, set reserved stirrups on the top of the prefabricated beams, set the reserved stirrups along the width direction of the prefabricated beams, and the prefabricated beams are divided into two sections;

[0059] Fabrication of prefabricated upper columns: embedded steel pipes are buried at the bottom of prefabricated upper columns, and the embedded steel pipes run through the prefabricated upper columns. The prefabricated upper columns are embedded with reserved longitudinal ribs for upper columns, and the reserved longitudinal ribs for upper columns are set and protruded along the length direction of prefabricated upper columns. on the bottom of the prefabricated upper column;

[0060] Making the prefabricated lower column: the top of the prefabricated lower column is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com