Mass concrete circulating cooling water automatic control cooling system and method

A large-volume concrete and circulating cooling water technology, which is applied in infrastructure engineering, architecture, building construction, etc., can solve the problems of large temperature difference and inability to cool down, so as to reduce the temperature difference, reduce labor costs, and reduce the risk of gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

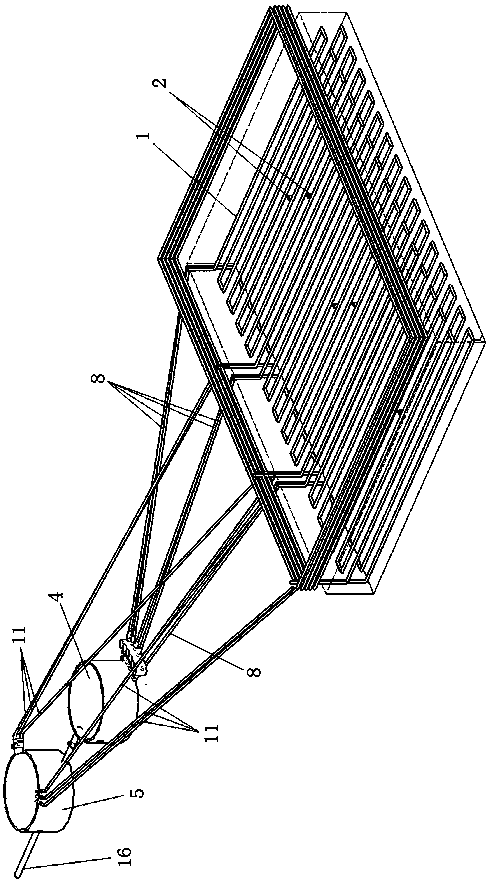

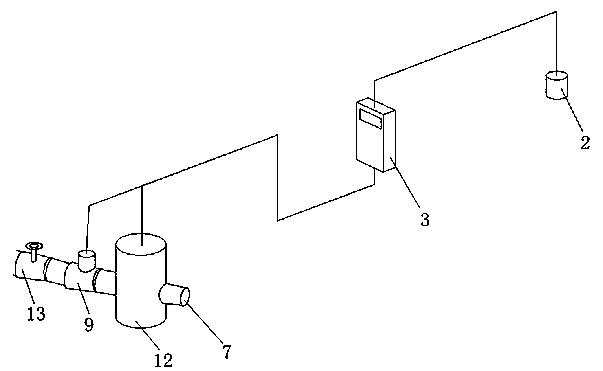

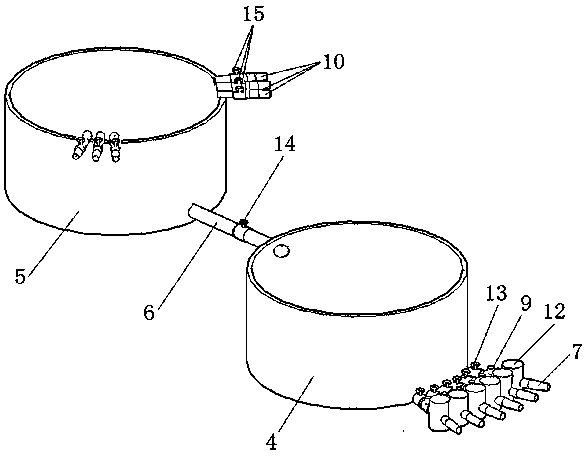

[0030] This embodiment provides a large-volume concrete circulating cooling water automatic control cooling system, such as figure 1 and figure 2 As shown, it includes a water collection tank, a cooling pipe 1, a temperature measuring element 2, a circulation mechanism connecting the water collection tank and the cooling pipe 1, and a temperature switch 3 connected with the temperature measurement element 2 and the circulation mechanism; the cooling pipe 1 is pre-buried in layers In the mass concrete, and each layer of cooling pipe 1 is composed of a plurality of mutually independent sub-pipes to divide the mass concrete into multiple areas; each sub-pipe is provided with a temperature measuring element 2; the temperature switch 3 is used to The temperature in the mass concrete measured by the temperature measuring element 2 controls the opening and closing of the circulation mechanism and the size of the water delivery after opening.

[0031] In the large-volume concrete ci...

Embodiment 2

[0045] This embodiment provides a method for automatically controlling the temperature reduction of circulating cooling water for large-volume concrete. The method is implemented based on the system for automatically controlling the cooling water for large-volume concrete circulating cooling water described in Example 1, and includes the following steps:

[0046] S1, the temperature measuring element 2 detects the temperature in the mass concrete, and feeds back the detected value to the temperature control switch 3;

[0047] S2, if the detected value is greater than the preset value of the temperature control switch 3, the temperature control switch 3 opens the solenoid valve 9, and controls the opening degree of the solenoid valve 9, and the cooling water flows into the sub-pipe.

[0048] Further, the following steps carried out after S2 are also included:

[0049] S3, after the temperature measuring element 2 detects that the temperature in the mass concrete drops below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com