Traction joint and method preventing steam from entering rubber sleeve cable

A technology for pulling joints and pulling wires, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of gaps in the coating layer, large infiltrating area, and increasing the risk of water seepage. The method is simple and the application range is wide. , the effect of reducing the permeable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

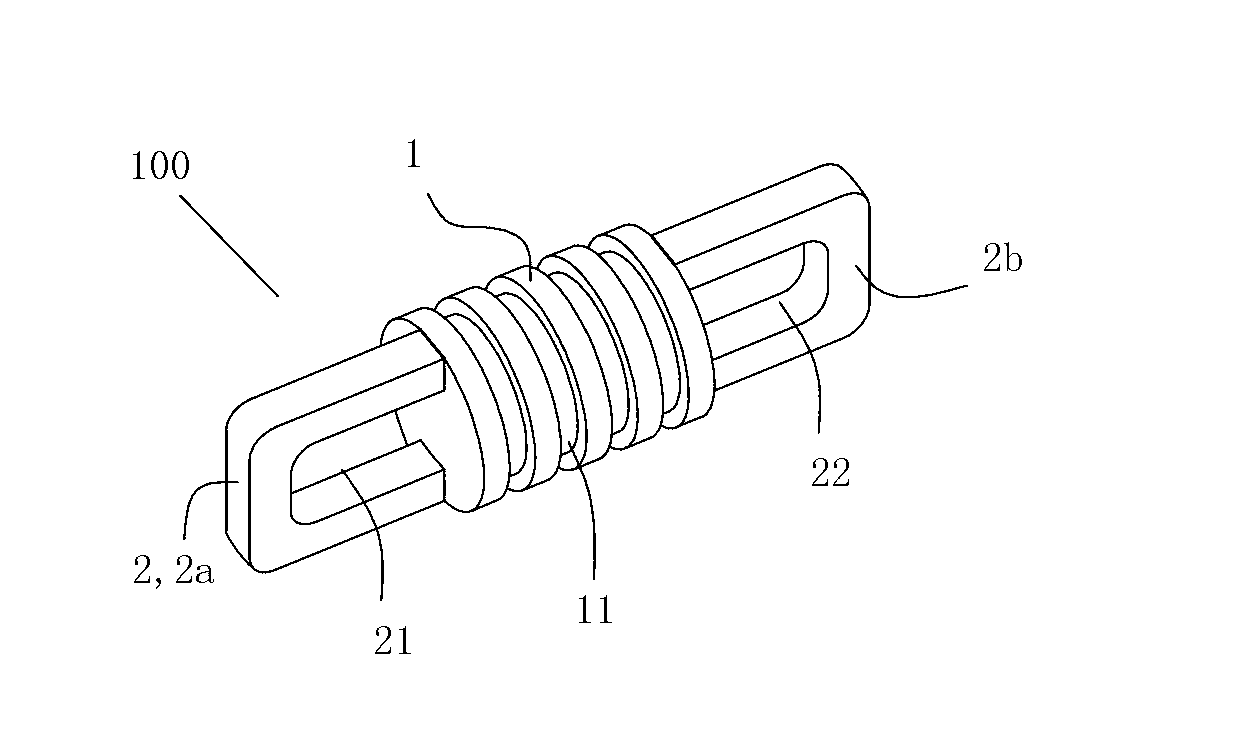

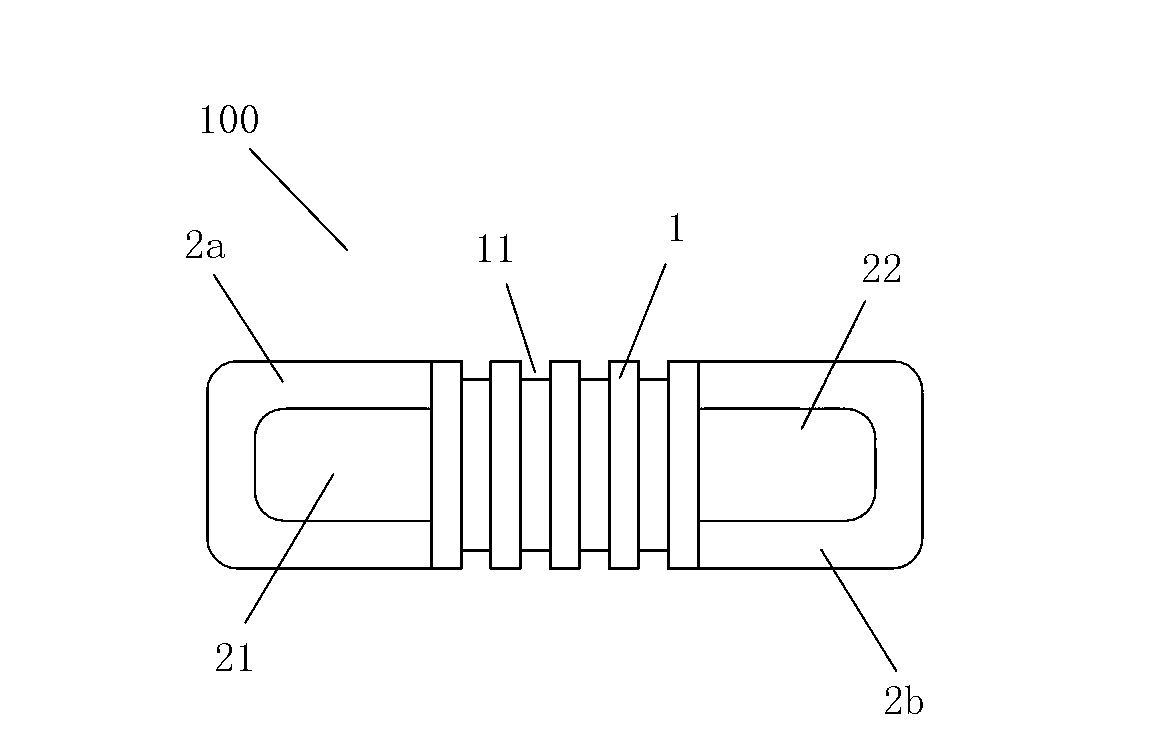

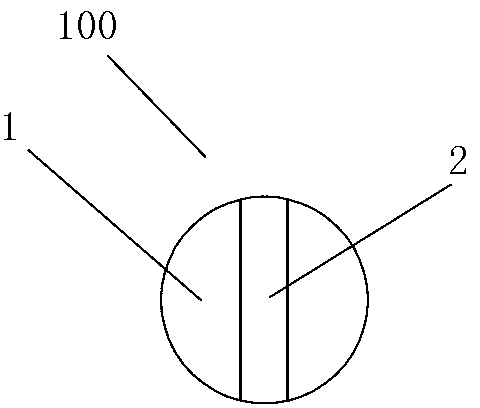

[0031] See Figure 1 to Figure 4, the traction joint 100 of the present invention is a steel integral piece, including a main body 1 and connecting parts 2 located on the left and right sides of the main body 1 . The main body 1 is in the shape of a cylinder whose axis is arranged along the left and right directions. The diameter of the main body 1 is 1 to 12 mm smaller than the diameter of the wire to be extruded. When the wire diameter of the outgoing line is 12 to 15 mm, the diameter of the main body 1 is 1 to 2 mm smaller than the wire diameter of the wire to be extruded; when the wire diameter of the wire to be extruded is 15 to 20 mm, the diameter of the main body 1 1 to 3 millimeters less than the diameter of the line to be extruded; when the diameter of the line to be extruded is 20 to 25 millimeters, the diameter of the main body 1 is 1 to 5 millimeters less than the diameter of the line to be extruded; When the wire diameter of the wire is 25 to 35 mm, the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com