Optical alignment method for shipbuilding central axis

A lighting and shafting technology, which is applied in shipbuilding, ship parts, ships, etc., can solve the problems of slowing down the loading speed of superstructures, reducing the strength of hull structures, wasting labor costs and material costs, and achieving the goal of improving shipbuilding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The lighting process method of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

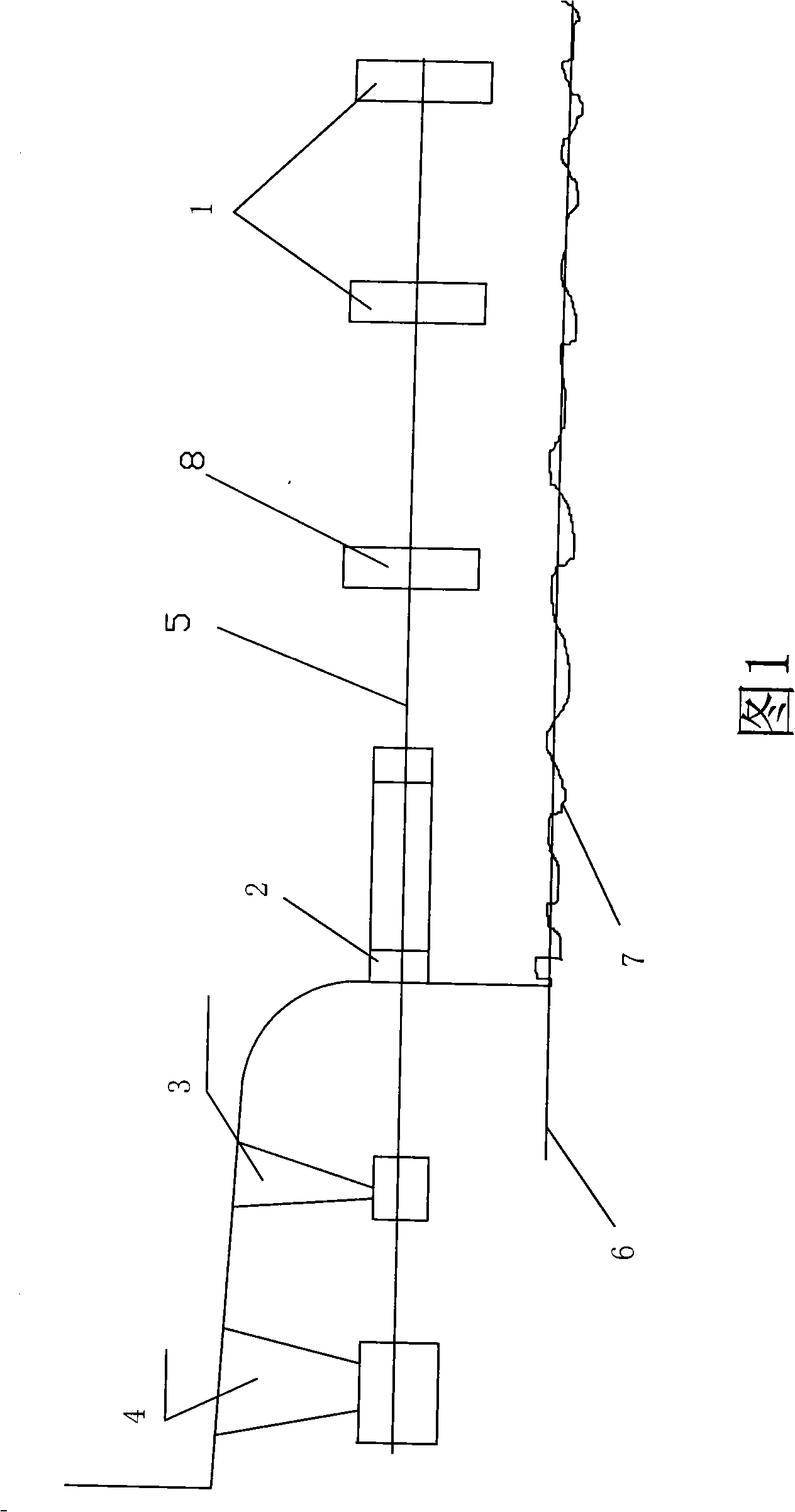

[0027] Taking a 75,000-ton bulk carrier as an example, the main engine is hoisted first and then the lighting process is used as an example to illustrate the practical application of the shafting lighting method in shipbuilding of the present invention. The bulk carrier includes four main engines and two gearboxes. The total weight of the above components reaches 200 tons. After being installed on the ship, the hull will sink and deform due to its own weight. The above deformation must be prevented and corrected during the ship construction process , to meet the design requirements of the ship. Under the premise that it is difficult to change the hull structure and the total amount of the main engine, it is necessary to change the construction sequence of the ship to achieve the above purpose. In the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com