Modular building component and on-site hoisting building method

A building and assembly technology, applied in building construction, construction, etc., can solve the problems of time-consuming and laborious labor intensity, difficult quality control, lag in production process, etc., and achieve the effect of saving labor, simple structure, and easy on-site construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

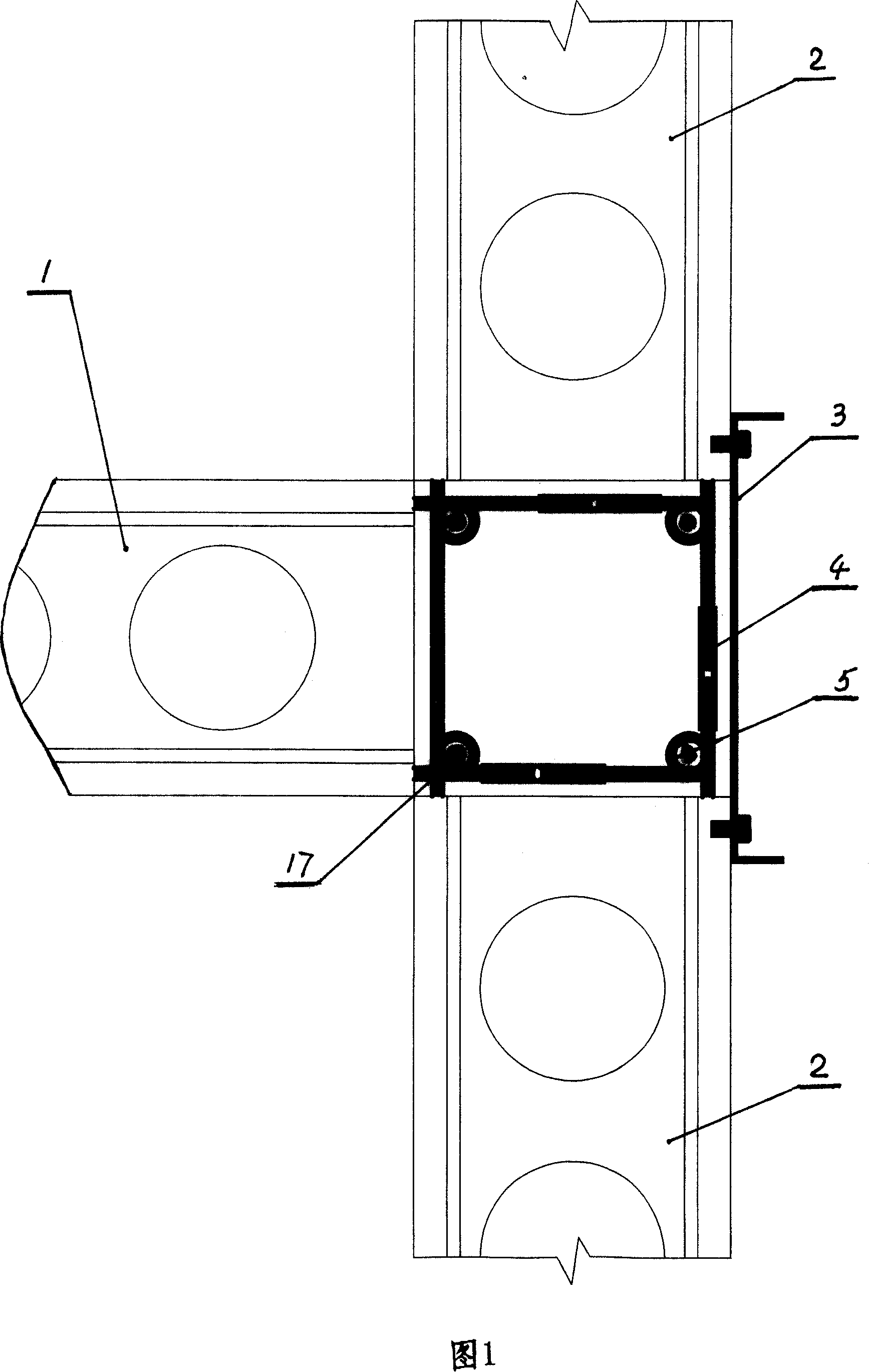

[0025] Referring to Figure 1, at the site, looking at the connection structure of the three wall panels from top to bottom, there are ring beam grooves on the three wall panels, and a square column at the connection of the three wall panels, and the belts fixed by the wall panels ( The stirrup bars 5 around the rings are connected as a whole through the horizontal position of the connecting sleeve 4, and the vertical ribs 17 of the structural columns are inserted in the rings of the upper and lower corresponding stirrup bars 5, and the formwork 3 is fixed outside the outer wall panel 2. Concrete 11 and stirrup bars 5 are added to form a connecting structural column with pouring and stamping, so that three boards are connected together to form a whole.

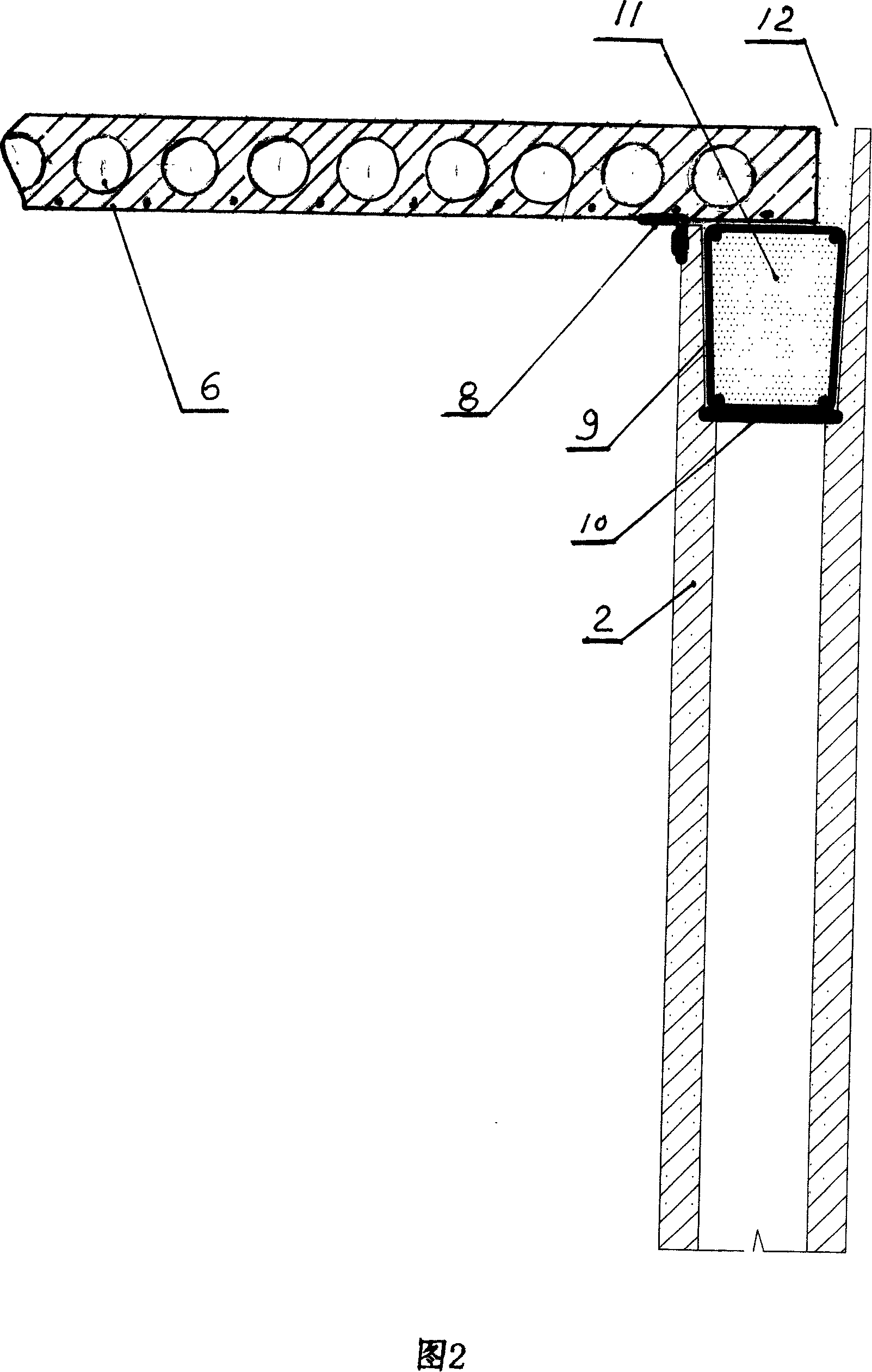

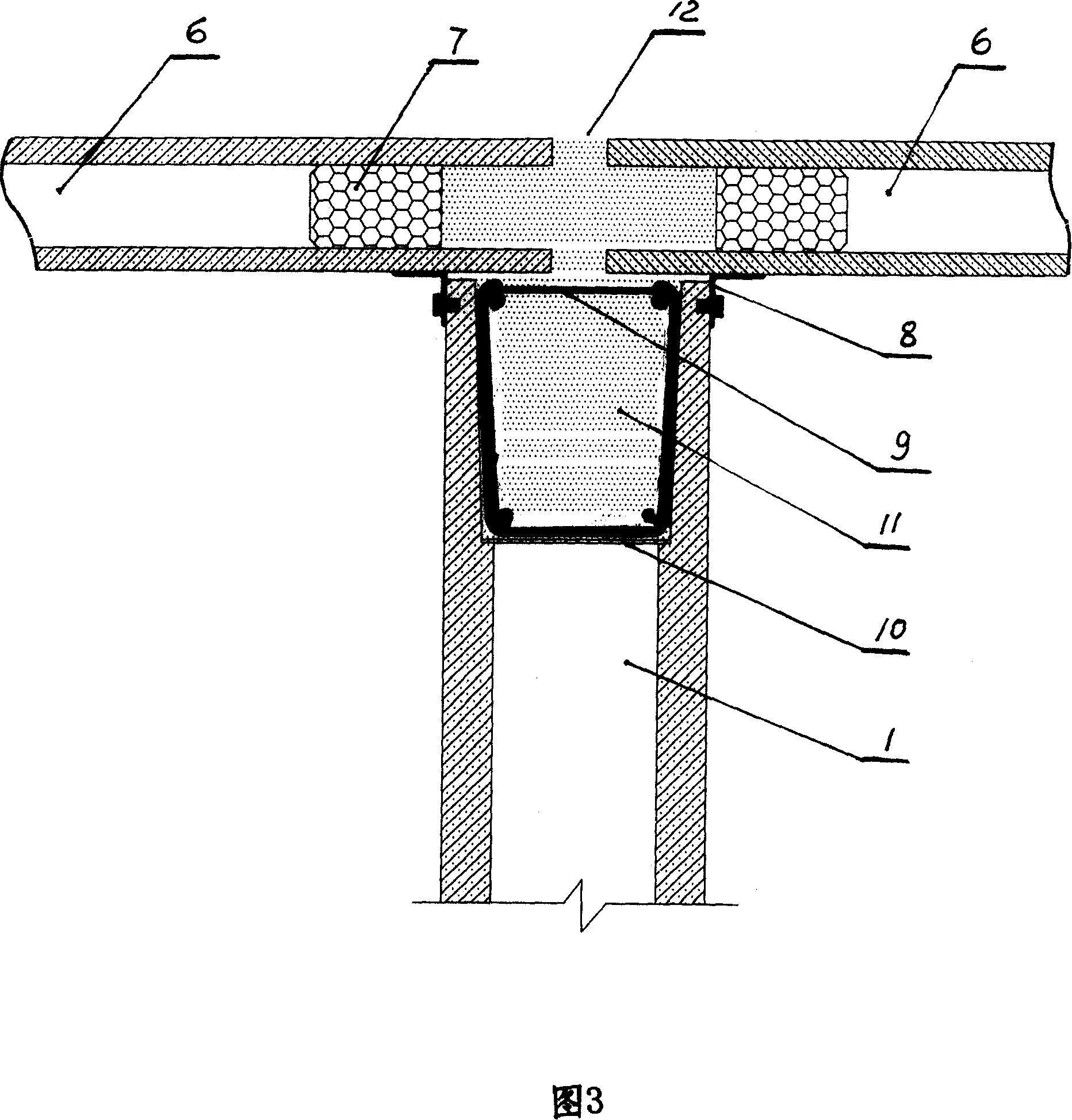

[0026] Referring to Fig. 2, it is the connection structure between the outer wall panel 2 and the floor slab 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com