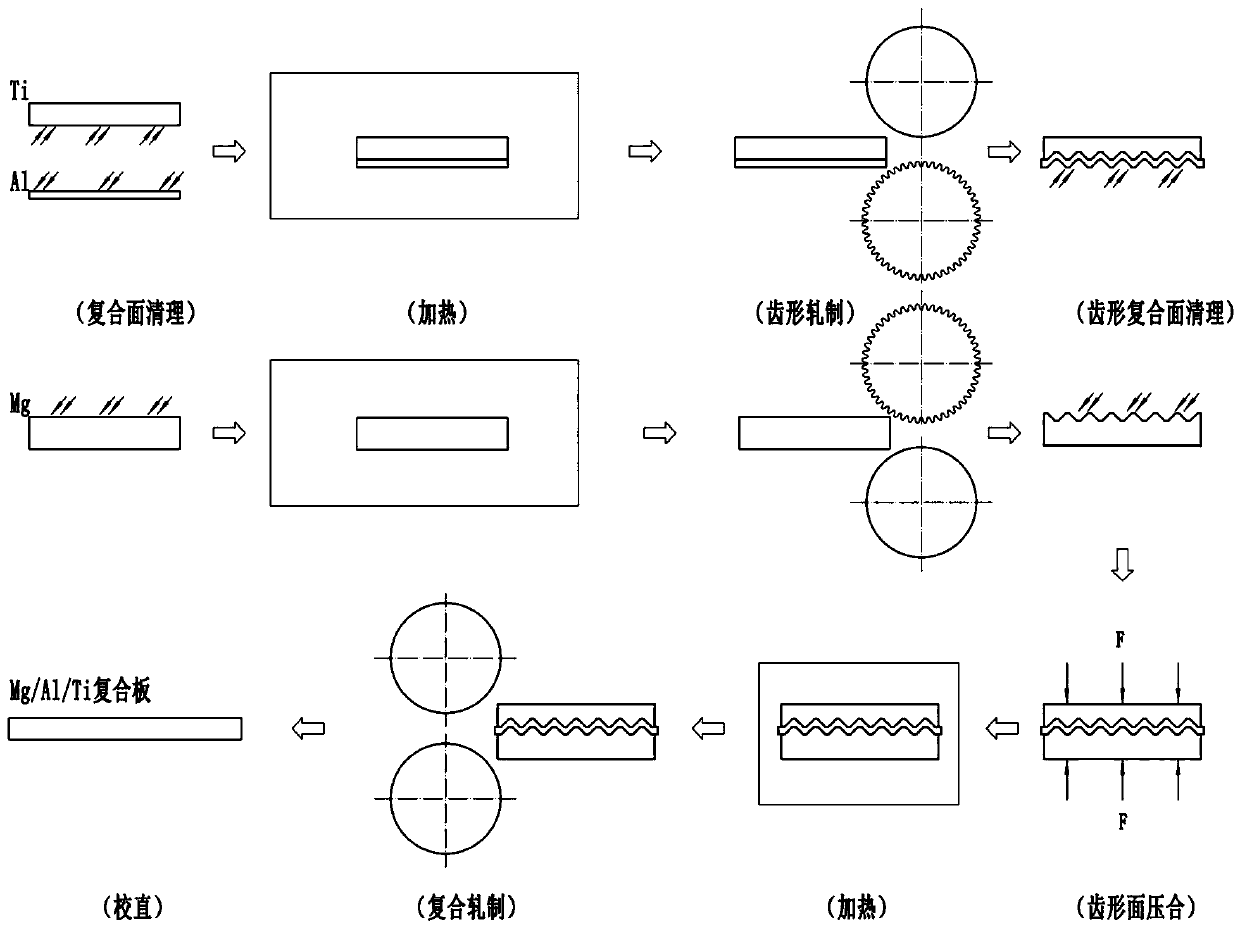

Rolling preparing method of tooth-shaped junction surface of titanium/aluminum/magnesium composite board

A composite plate and composite surface technology, which is applied in the field of rolling and preparation of toothed junction surfaces, can solve the problems of large deformation resistance, low interface strength, affecting the composite effect of titanium/aluminum, etc., and achieves good vibration damping performance and electromagnetic shielding performance. Good interface quality and the effect of increasing the composite contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: AZ31 magnesium alloy + 3003 aluminum alloy + TC4 titanium alloy composite plate rolling (thick plate).

[0026] Take a piece of 3mm thick AZ31 magnesium alloy, 2mm thick 3003 aluminum alloy and 1mm thick TC4 titanium alloy, and the length and width dimensions are 90mm×45mm;

[0027] Grind the composite surface of the three alloys with a wire brush until the roughness is uniform, clean the polished surface with alcohol and dry it;

[0028] Lay the composite surfaces of TC4 titanium alloy and 3003 aluminum alloy plates together, heat them to 450°C, keep them warm for 8 minutes, and then roll them together on a rolling mill with toothed rolls. The preheating temperature of the rolls is 150°C. The lower amount is 8%, and the composite surface of TC4 and 3003 after rolling is a toothed surface;

[0029] The AZ31 magnesium alloy sheet is heated to 300°C, held for 10 minutes and rolled on a rolling mill with toothed rolls, the preheating temperature of the rolls...

Embodiment 2

[0033] Embodiment 2: AZ91 magnesium alloy+6062 aluminum alloy+TC4 titanium alloy composite plate rolling (thick plate).

[0034] Take a piece of 3mm thick AZ91 magnesium alloy, 2mm thick 6062 aluminum alloy and 1mm thick TC4 titanium alloy, and the length and width dimensions are 90mm×45mm;

[0035] Grind the composite surface of the three alloys with a wire brush until the roughness is uniform, clean the polished surface with alcohol and dry it;

[0036] Lay the composite surface of TC4 titanium alloy and 6062 aluminum alloy sheet together, heat it to 550°C, keep it warm for 8 minutes, and roll it on a rolling mill with toothed rollers. The preheating temperature of the roll is 150°C, and the total pressure The lower amount is 8%, and the composite surface of TC4 and 6062 after rolling is a toothed surface;

[0037] The AZ91 magnesium alloy plate is heated to 350°C, and after 10 minutes of heat preservation, it is rolled on a rolling mill with toothed rolls, the preheating t...

Embodiment 3

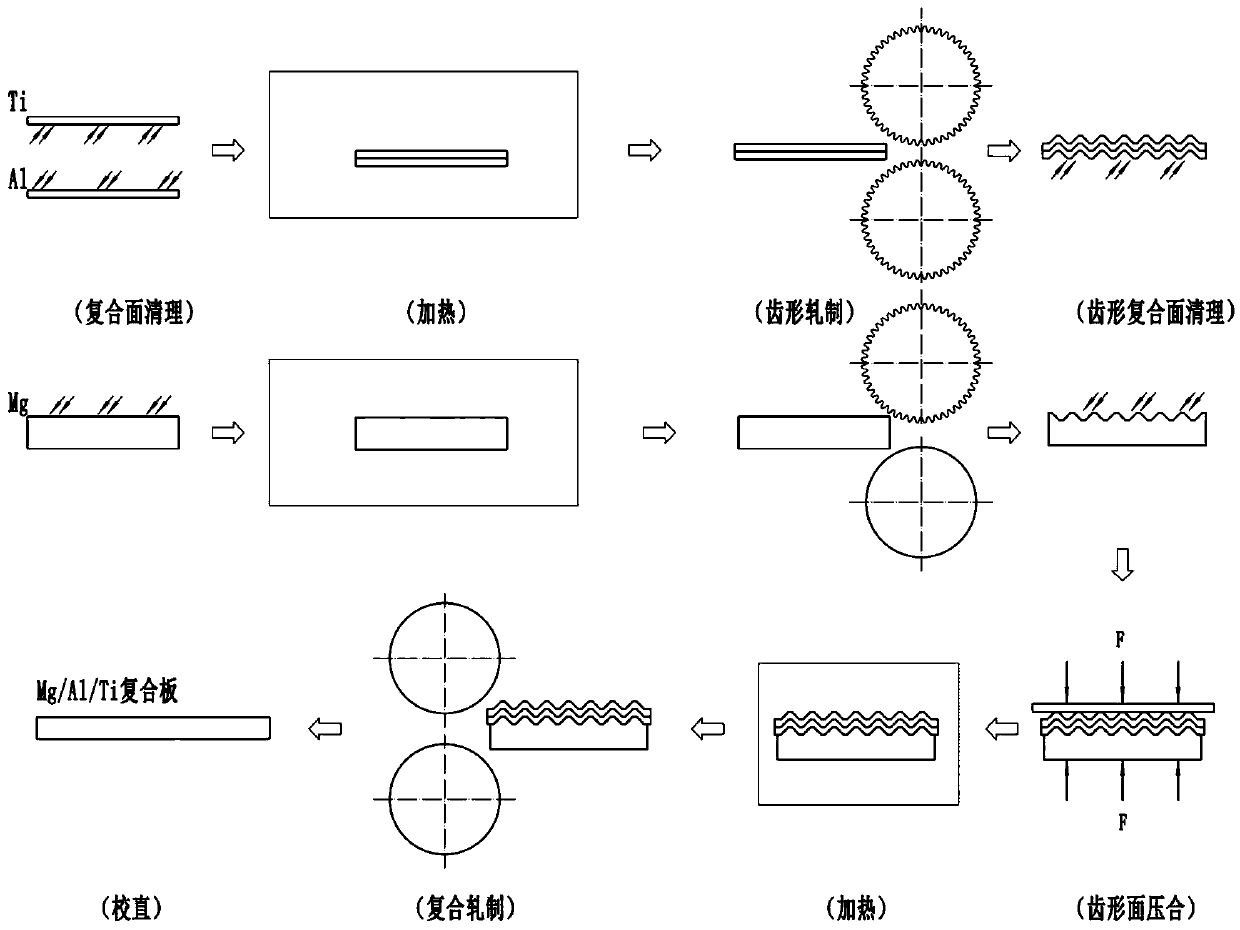

[0041] Embodiment 3: AZ31 magnesium alloy+6062 aluminum alloy+TC4 titanium alloy composite plate rolling (thin plate).

[0042] Take one piece of 3mm thick AZ31 magnesium alloy, 1mm thick 6062 aluminum alloy and TC4 titanium alloy, the length and width dimensions are 90mm×45mm;

[0043] Grind the composite surface of the three alloys with a wire brush until the roughness is uniform, clean the polished surface with alcohol and dry it;

[0044] Lay the composite surface of TC4 titanium alloy and 6062 aluminum alloy sheet together, heat it to 550°C, keep it warm for 8 minutes, and roll it on a rolling mill with two toothed rollers. The preheating temperature of the roll is 150°C. The total reduction is 10%, and both sides of the TC4 and 6062 composite plates are toothed after rolling;

[0045] The AZ31 magnesium alloy sheet is heated to 300°C, held for 10 minutes and rolled on a rolling mill with toothed rolls, the preheating temperature of the rolls is 150°C, and the reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com