Heat-storage heat-preserving building block and manufacturing and installation method

A technology of thermal insulation block and installation method, which is applied in the direction of building materials, etc., can solve the problems of waste of land resources, large wall thickness, poor thermal insulation, etc., and achieve an effect that is conducive to popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

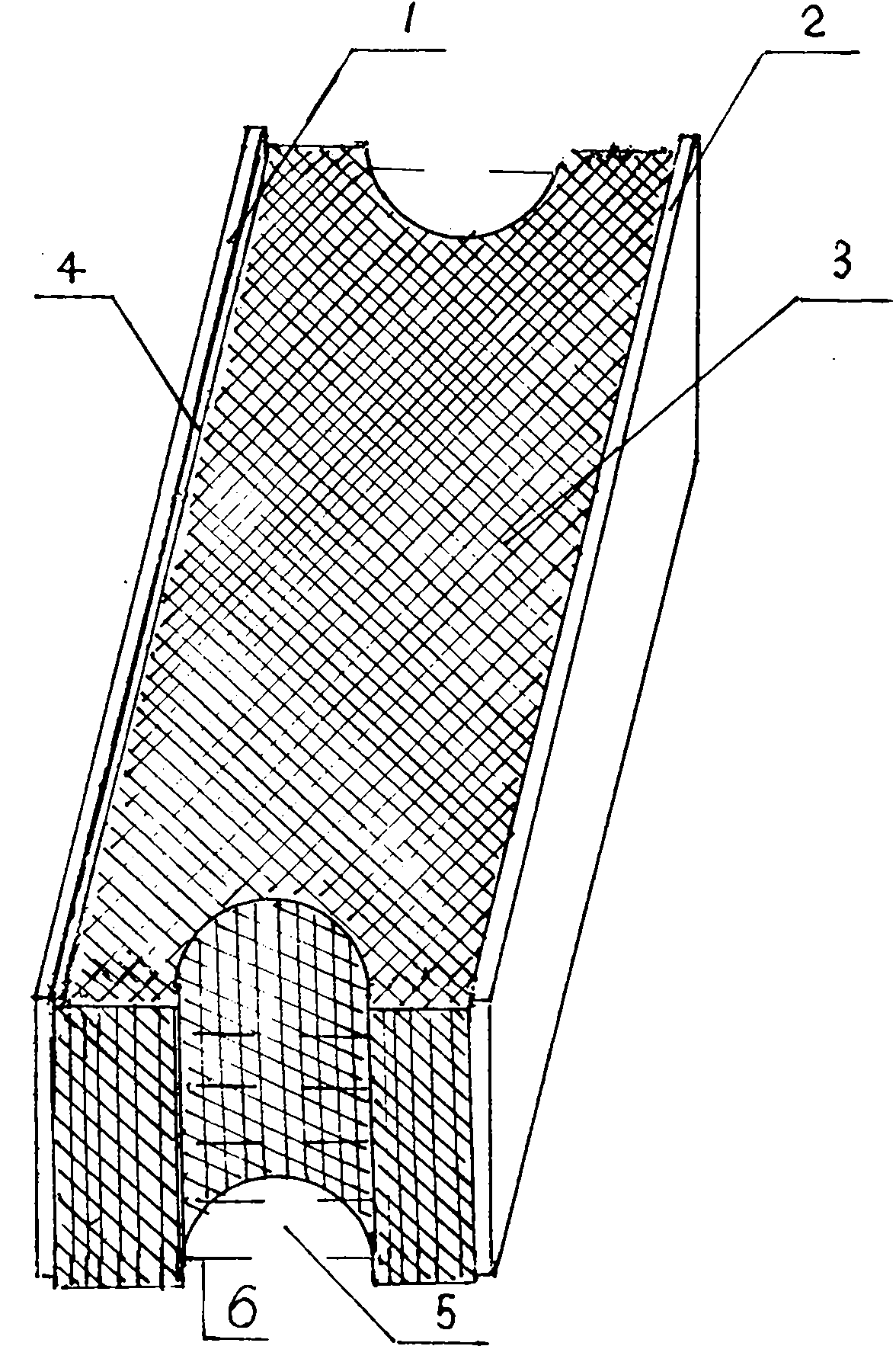

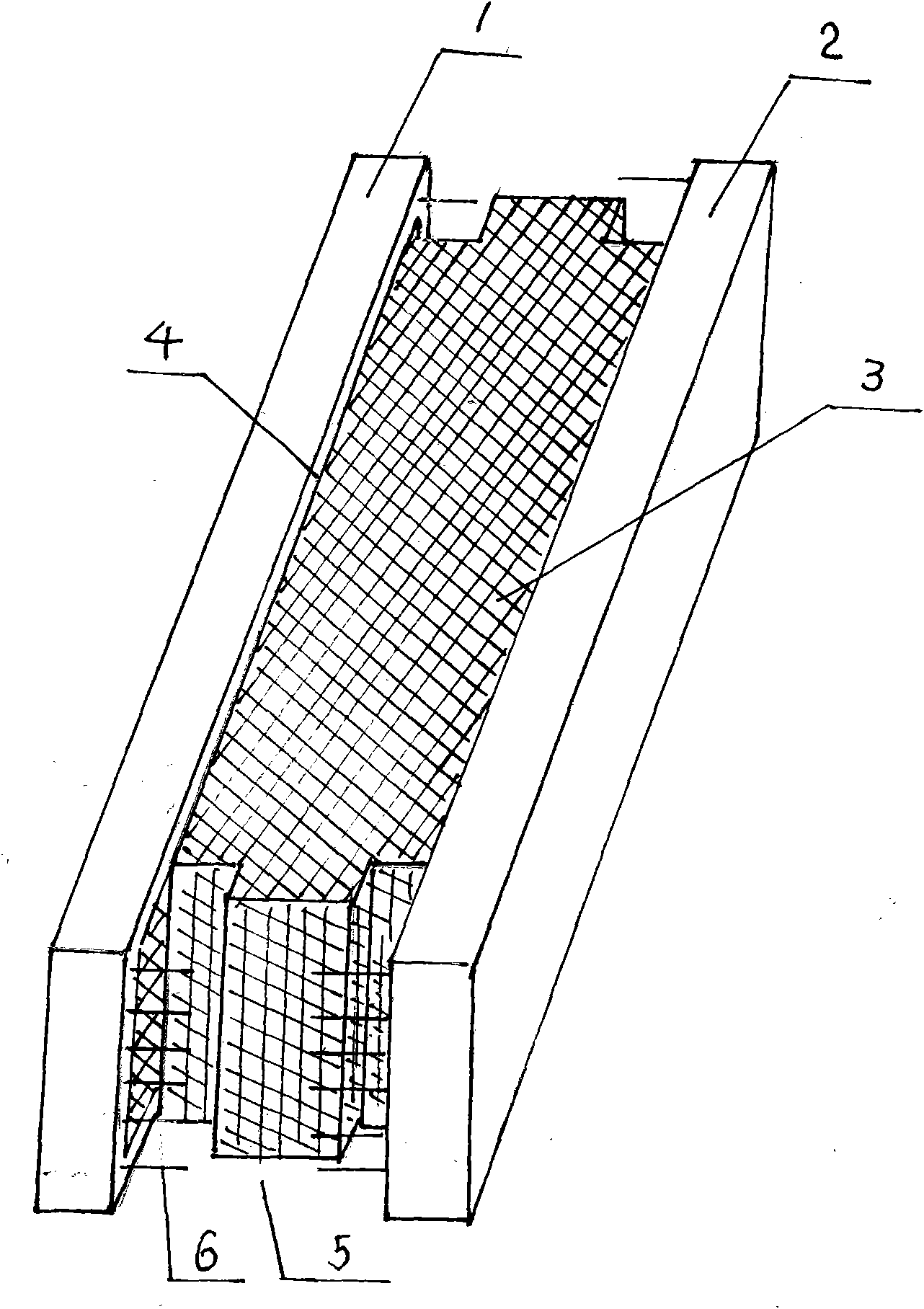

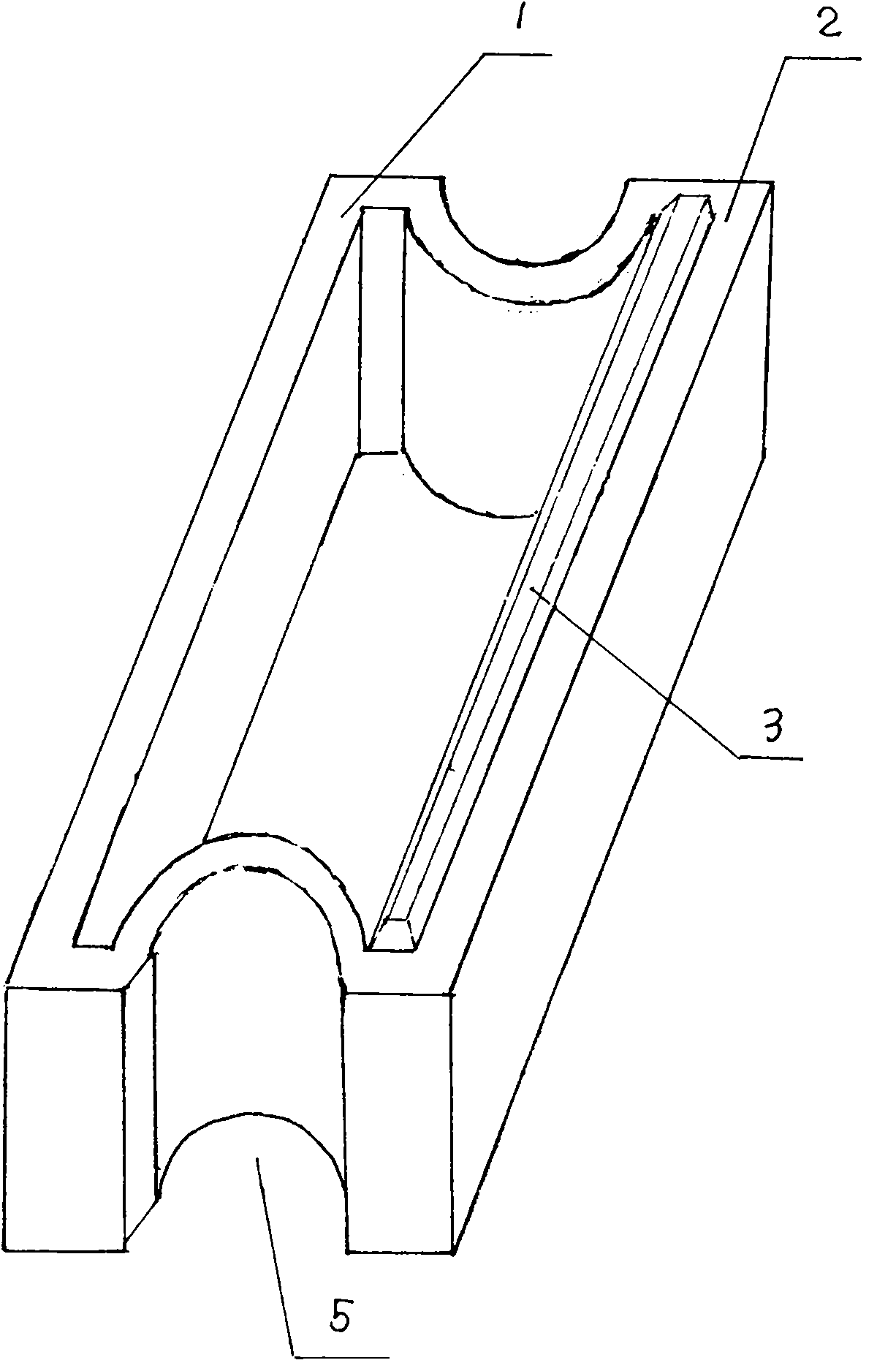

[0020] Manufacture of blocks by step-by-step method: when manufacturing a rectangular box shell, support a mold with a length of 1200mm, a width of 350mm, and a height of 50mm on the platform, and apply a release agent inside; use 42.5 grades of cement and coarse sand , calcium-based bentonite, polymer emulsion, according to the weight ratio 1:1:0.1:0.1, add appropriate amount of short chemical fiber, water reducer, defoamer, water, and stir to form a thick slurry; firstly wipe it into the mold 0.5mm by hand Thick thick slurry, laying alkali-resistant glass fiber mesh cloth as the outer reinforcement layer, then pouring 10mm thick thick slurry into the mold, laying two cold-drawn steel meshes welded with prefabricated iron of X-shaped connecting bridge bars It is the inner reinforcement layer, and then smeared into the mold with a thick slurry of 0.5mm thick, and made a box shape with a height of 50mm around it as the shell 1 and 2; after drying and demoulding, the connecting b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com