Fireproof precoated sand and preparation method thereof

A coated sand and refractory technology, which is applied in the field of coated sand, can solve problems such as sand sticking defects in castings, achieve the effects of avoiding veining defects, avoiding mechanical sand sticking, and improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

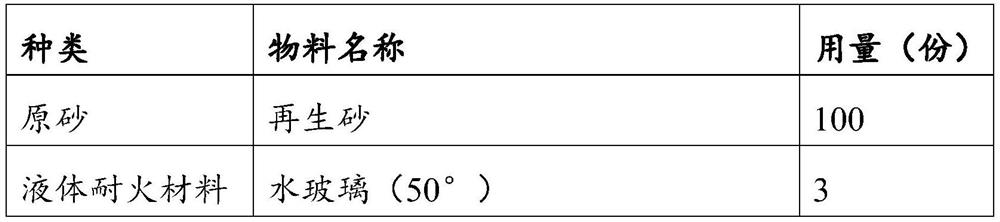

[0036] This embodiment provides a kind of refractory coated sand, which is formed by reacting the following materials in parts by weight:

[0037]

[0038]

[0039] The preparation technology of present embodiment coated sand, comprises the steps:

[0040] (1) Raw sand treatment:

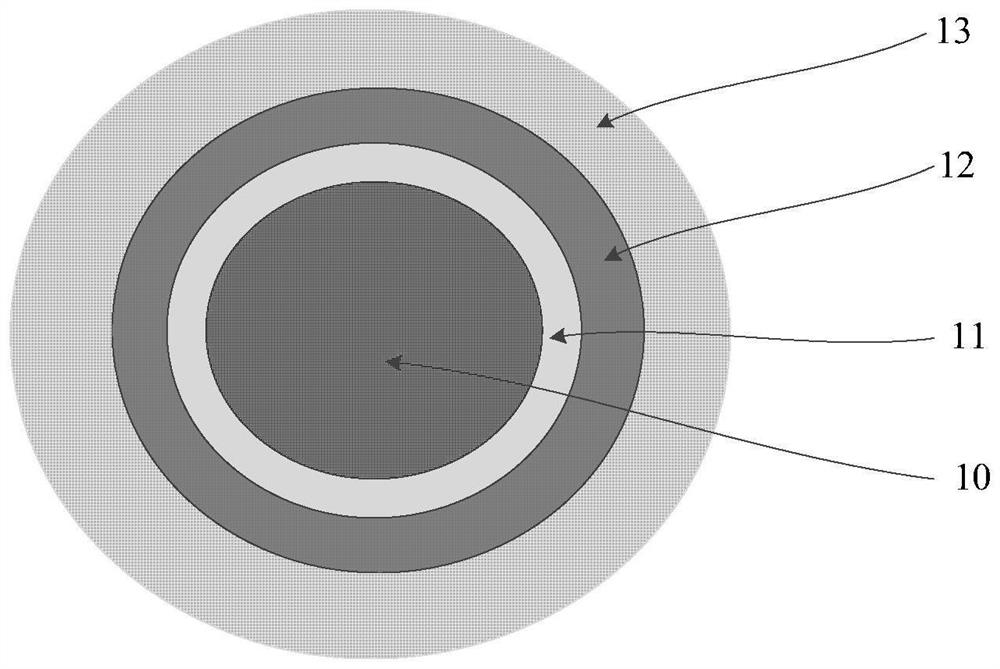

[0041]The raw sand is heated, and the heating temperature is required to be in the range of 180°C to 250°C. The heated raw sand enters the roller sand mixer, and then the liquid refractory material is added. Adjust the rotation speed of the wheel-type sand mixer to 20-30R / s, and stir at this speed for 60-80s to ensure that the active ingredients in the liquid refractory material are evenly coated on the surface of the silica sand particles, and completely solidified on the surface of the silica sand particles to form a hardened layer , to get the first refractory sand material, at this time the corresponding surface layer is called "refractory film layer".

[0042] (2) Sand coating:

[004...

Embodiment 2

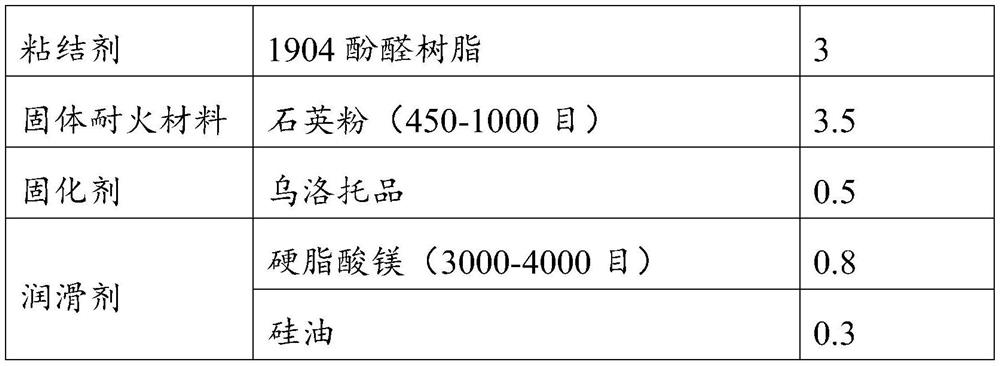

[0048] This embodiment provides a kind of refractory coated sand, which is formed by reacting the following materials in parts by weight:

[0049]

[0050] The preparation process of the refractory coated sand of this embodiment is basically the same as that of Embodiment 1.

Embodiment 3

[0052] This embodiment provides a kind of refractory coated sand, which is formed by reacting the following materials in parts by weight:

[0053]

[0054] The preparation process of the refractory coated sand of this embodiment is basically the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com