Furniture metal door plate

A door panel and metal technology, which is applied in the field of furniture door panels, can solve the problems that the connectors and aluminum alloy side strips are difficult to connect firmly, affect the performance of the door panel, and destroy the integrity of the door panel, etc., so that the appearance of the door panel has no exposed accessories and is rich in options. sex, gap tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0029] The structure and manufacturing process of the novel furniture metal door panel provided by the invention are as follows:

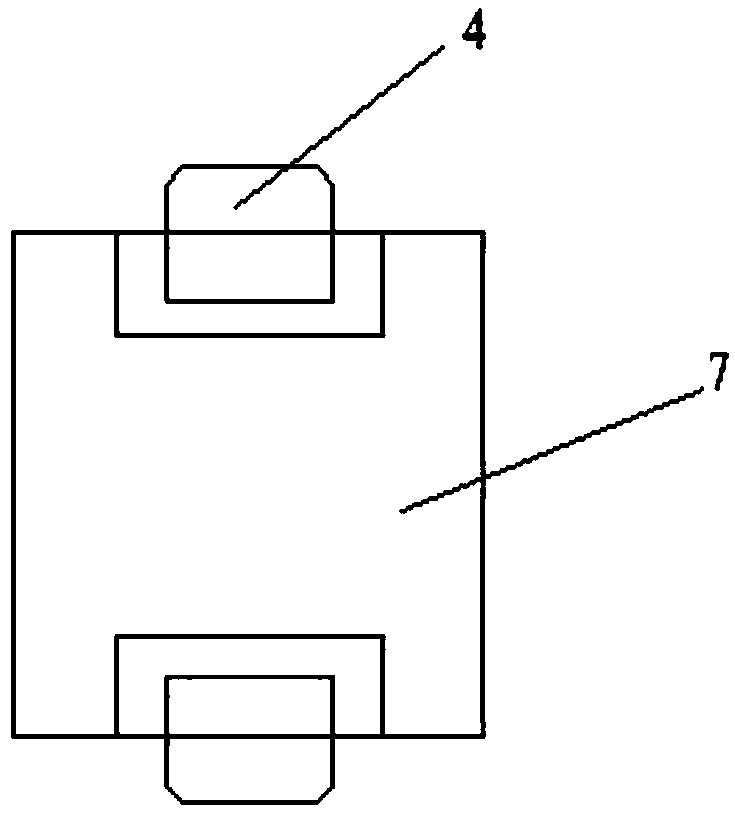

[0030] The furniture metal door panel includes a door panel body 1 and an aluminum alloy frame 2 .

[0031] First process the edge strip of aluminum alloy;

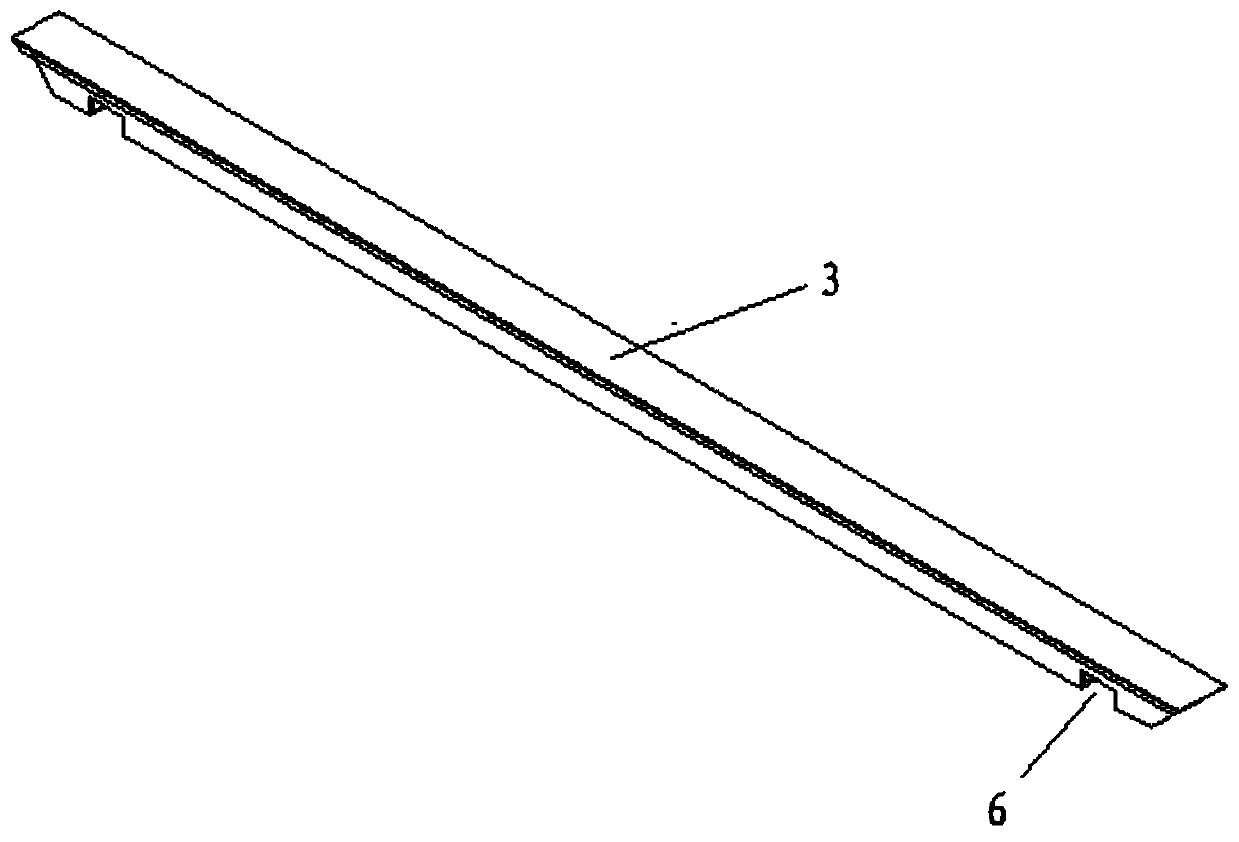

[0032] The regular size of the aluminum alloy side bar 3 is 4 meters long. It needs to be sawed off according to the length, and then a 45-degree bevel is sawed at both ends with a 45-degree saw, so that the four sawn aluminum alloy bars can be connected end to end. A rectangular closed frame is formed, that is, the aluminum alloy frame 2. The following design solution solves the problem of connection and fixation of the aluminum alloy frame 2 without screws and without exposure.

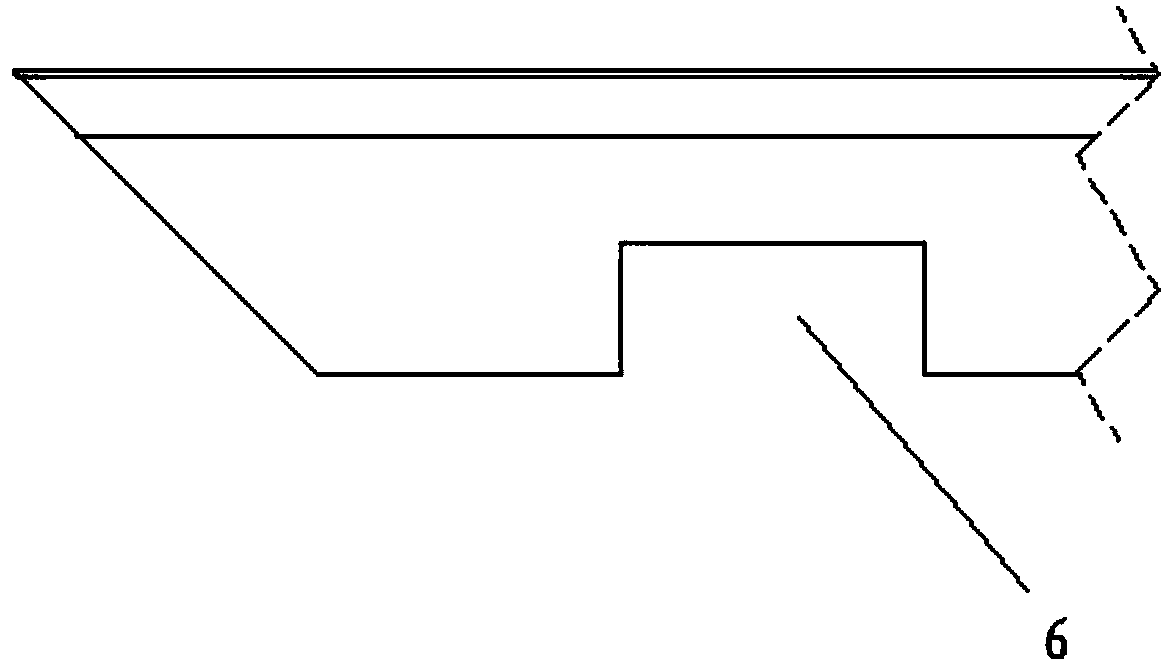

[0033] Such as figure 1 , figure 2 As shown, a rectangular notch 6 is separated by an alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com