Manufacturing method of industrial logistics supporting plate by using wood plastic die-casting

A production method and pallet technology, which is applied in the directions of biological packaging, sustainable packaging industry, sustainable manufacturing/processing, etc., can solve the problems of easy bending deformation, easy rust, low load strength of the pallet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

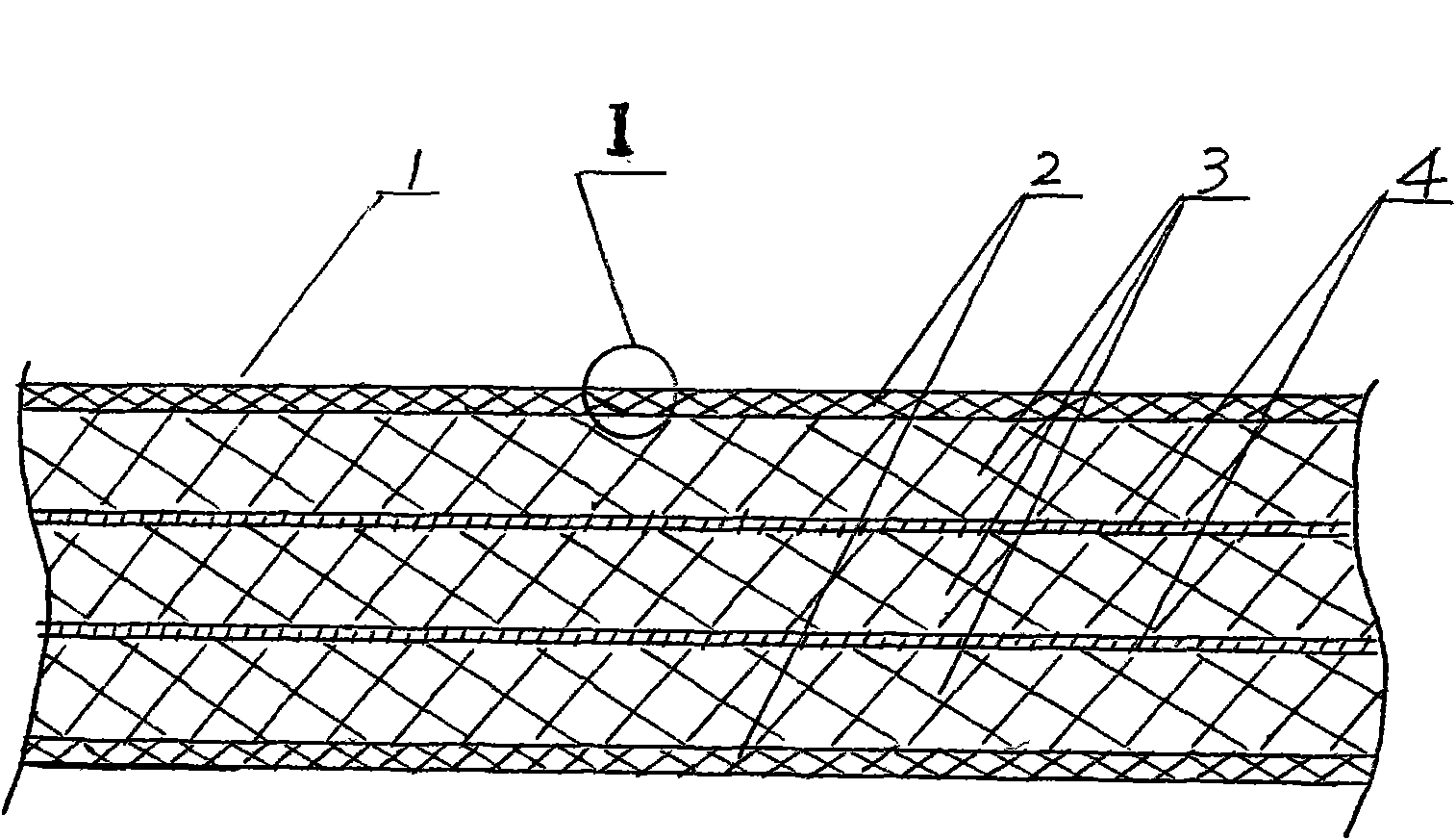

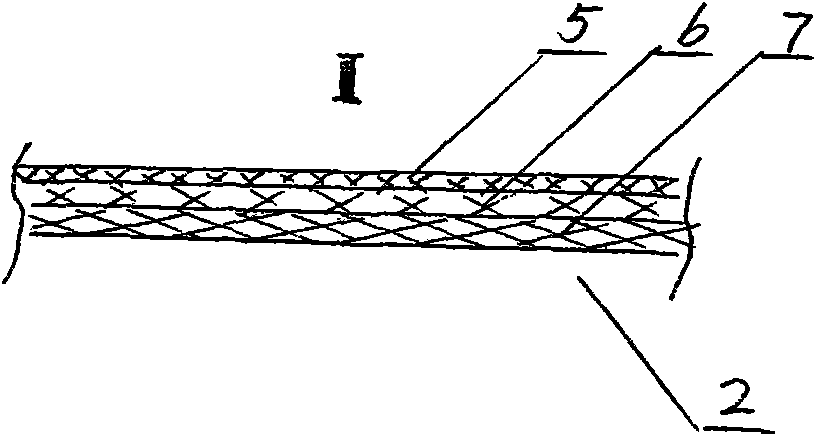

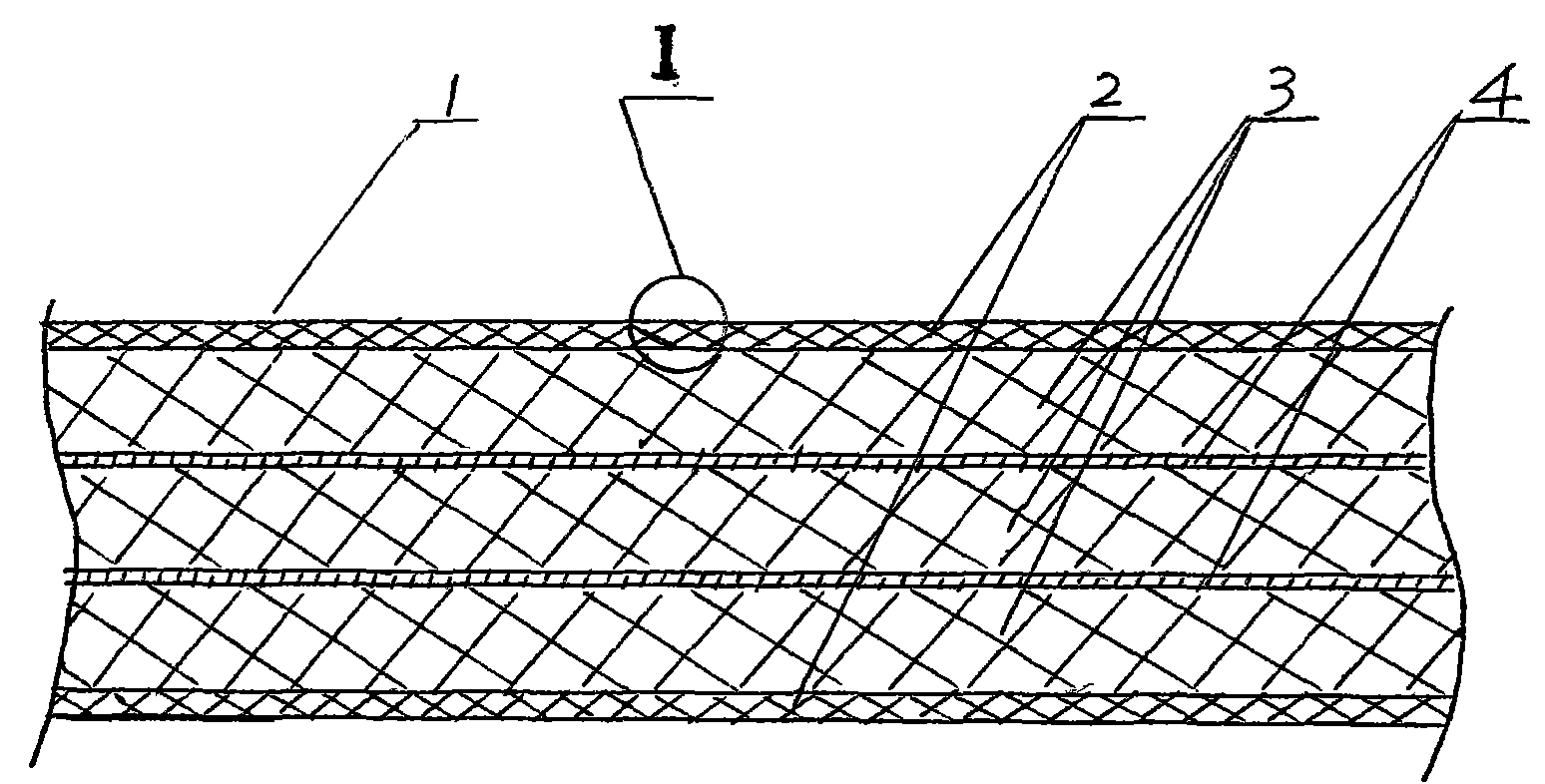

[0008] Made as attached figure 1 and 2 Take the flat logistics pallet 1 shown as an example. First, mix the ingredients, crush the waste bamboo and wood into needle-like chips, crush the waste rubber into powder, and crush the waste and old plastics into flakes or granules. , rubber powder, plastic fragments or granules are mixed according to the proportion of 25%, 15% and 60% by weight respectively to prepare the core material, and the weight of the pallet product is calculated according to the requirements. The weights corresponding to the weight percentages of the above three materials respectively. Then choose the corresponding mold and lay materials into the mold. First, lay the bottom fabric, that is, lay a layer of kraft paper, a layer of plastic cloth, and a layer of glass fiber cloth in turn; Steel mesh, another layer of core material, another piece of steel mesh, and then the fabric, that is, one layer of glass fiber cloth, one layer of plastic cloth, and one layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com