Single layer FRP concrete composite bridge slab construction method

A technology of FRP board and construction method, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of increasing the amount of FRP materials, not being able to fully play the role, and using a large amount of FRP materials, so as to achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

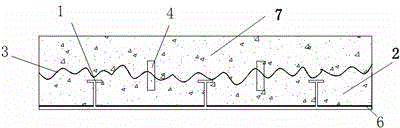

[0027] The single-layer FRP-concrete composite bridge deck of the present embodiment is as figure 1 and figure 2 As shown, it includes an FRP slab 1, on which concrete 5 is poured, and the concrete 5 includes a first layer of concrete 2 and a second layer of concrete 7 poured in sequence, and there is an interface 3 between the first layer of concrete and the second layer of concrete , the interface is pierced with connecting steel bars 4 at intervals.

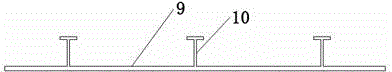

[0028] Such as image 3 As shown, the FRP board includes an FRP board bottom plate 9 and an FRP board rib 10 , wherein the cross section of the FRP board rib 10 is T-shaped, and epoxy resin glue is coated on its surface.

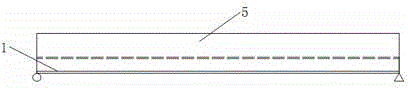

[0029] Such as Figure 4 As shown, the FRP slab 1 and the concrete 5 poured on it together form a single-layer FRP-concrete composite bridge deck, and the composite slab is erected on a steel beam 8 .

[0030] figure 1 The thickness of the bottom plate of the middle FRP plate is 10mm, the height of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com