Composite inorganic hydrous salt phase-change material and preparation method of inorganic composite phase-change plate

A technology of inorganic hydrated salts and phase change materials, applied in the field of composite building decoration materials, can solve the problems of supercooling and application of bound solid-liquid phase change materials, etc., and achieve the effects of good toughness, small degree of supercooling and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

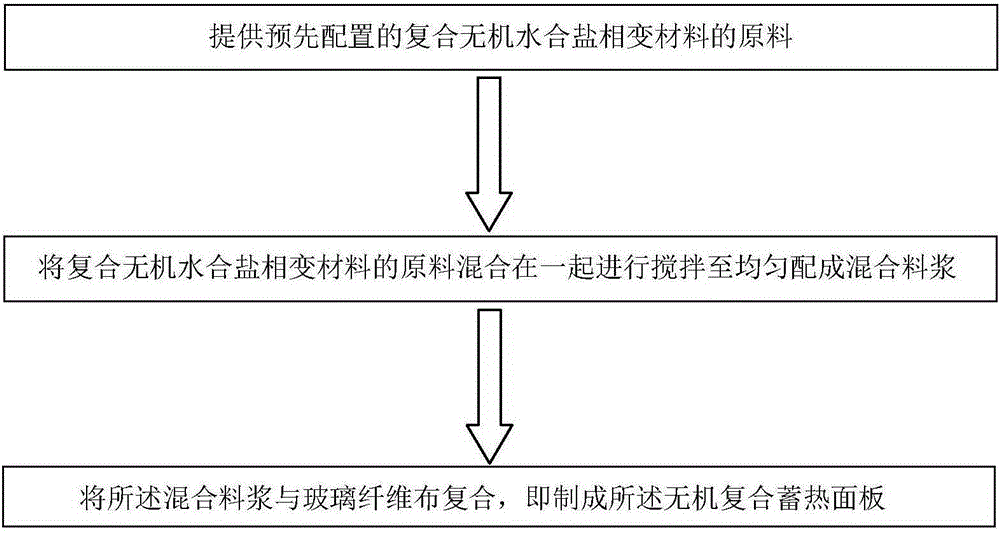

[0035] Based on the above-mentioned composite inorganic hydrated salt phase change material, the present invention also provides a high-performance inorganic composite phase change plate applied to interior decoration, and its preparation method is as follows: figure 1 Shown, specifically include the following:

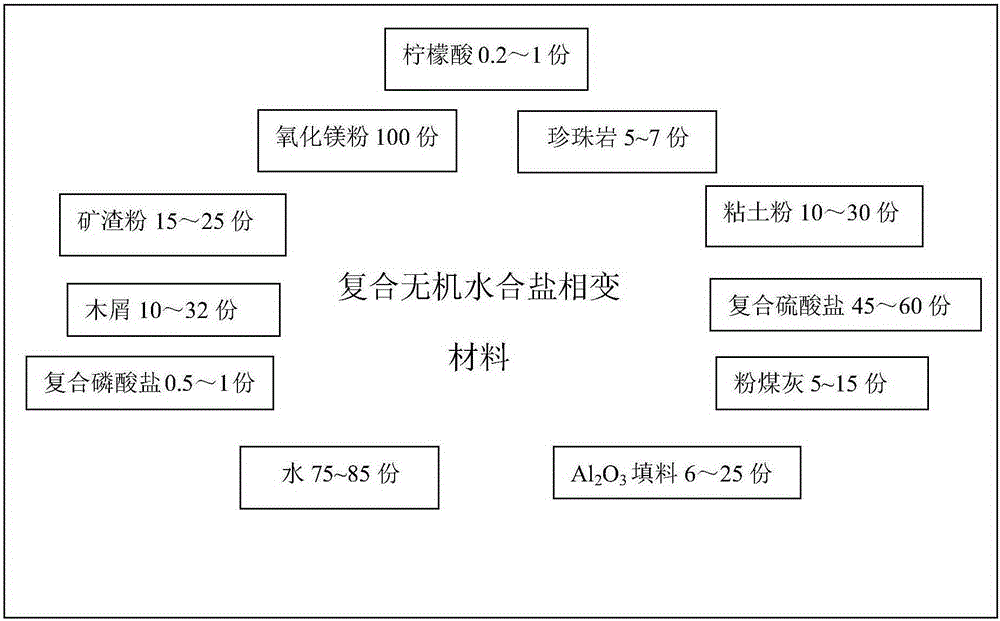

[0036] Step S1, providing pre-configured raw materials for composite inorganic hydrated salt phase change materials, the weight ratio of the raw materials is: 100 parts of magnesium oxide powder, 10-30 parts of clay powder, 15-25 parts of slag powder, Al 2 o 3 6-25 parts of filler, 45-60 parts of compound sulfate, 10-32 parts of sawdust, 0.5-1 part of compound phosphate, 5-7 parts of perlite, and 75-85 parts of water. Its ratio is as follows figure 2 shown.

[0037] Phase change materials are a class of materials that can absorb heat (cold) from the environment during their own phase transition, and release heat (cold) to the environment when needed, thereby achie...

Embodiment 1

[0060] An inorganic composite phase change board, comprising the following raw materials in parts by weight: 100 parts of magnesium oxide powder, 20 parts of laterite powder, 5 parts of attapulgite, 10 parts of fly ash, 10 parts of kaolin, 60 parts of composite sulfate, wood chips 30 parts, 0.5 parts of citric acid, 0.5 parts of calcium dihydrogen phosphate, 75 parts of water, and 0.6 parts of foaming agent.

[0061] Mix the raw materials of the above-mentioned inorganic composite phase change plate (except the foaming agent) together, then add water (the ratio of the weight of the added water to the weight of the magnesium oxide powder is 75:100) and stir until it is uniformly formed When mixing the slurry, when stirring, the stirring time is controlled within 12 to 18 minutes according to the characteristics of the slurry, and the stirring temperature of the slurry is controlled above 10°C and below 25°C. Then use a foaming machine to make a stable foam from the foaming agen...

Embodiment 2

[0067] An inorganic composite phase change plate, comprising the following raw materials in parts by weight: 100 parts of magnesium oxide powder, 20 parts of laterite powder, 5 parts of attapulgite, 10 parts of fly ash, 10 parts of bauxite, 5 parts of kaolin, compounded 60 parts of sulfate, 30 parts of wood chips, 0.5 parts of citric acid, 0.5 parts of calcium dihydrogen phosphate, 80 parts of water, and 0.6 parts of foaming agent.

[0068] The inorganic composite phase change plate obtained according to Example 2 has a thickness of 9mm and a density of 1.2g / cm 3 , The dry flexural strength is 33.5mPa, the wet flexural strength is 29.5mPa, and the softening coefficient is 0.88. After soaking in water for three months, the softening coefficient is 0.87.

[0069]Using Example 2 for indoor partition boards, its excellent phase-change energy storage performance greatly reduces the energy consumption of heating and air-conditioning equipment, and controls the humidity well to ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com