Preparation method of polymethyl methacrylate based cell gradient material

A technology of polymethyl methacrylate and gradient materials, which is applied in the field of gradient materials, can solve the problems of not using adhesive-free cell gradient materials, and achieve the effects of environmental protection, simple process, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

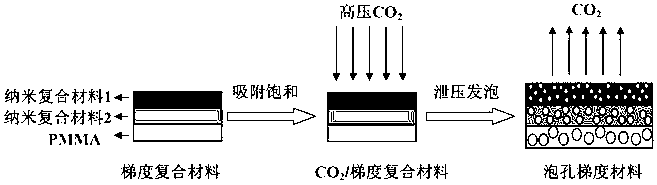

Method used

Image

Examples

specific example 1

[0028] 1. Disperse 0.5wt.% silver nanoparticles and 0.5wt.% carbon nanotubes evenly into the PMMA matrix to prepare Ag / PMMA and CNTs / PMMA nanocomposites.

[0029] 2. Laminate CNTs / PMMA, Ag / PMMA and pure PMMA sheets, melt and hot press at 210°C to form a gradient composite material.

[0030] 3. Put the prepared gradient composite material in the autoclave, blow it with a small amount of carbon dioxide for 3 minutes, then raise the temperature of the autoclave to 95°C, then use the syringe pump to inject carbon dioxide to 20MPa, and saturate at constant temperature and pressure for 6h. Gradient composite materials saturated with carbon dioxide adsorption are obtained.

[0031] 4. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, remove the heating device after 60 seconds, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

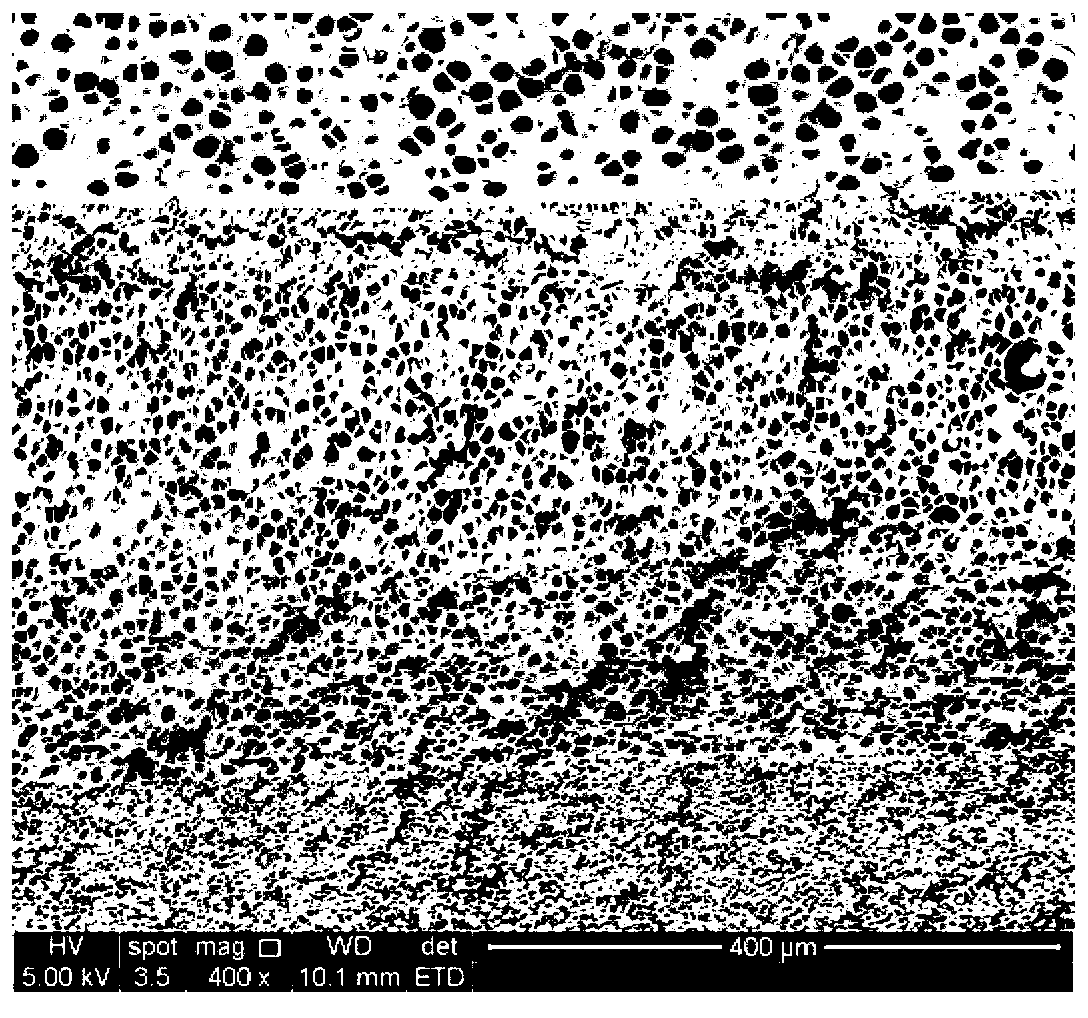

[0032] The cell structure of the cell gradient material is as follows fi...

specific example 2

[0034] 1. 0.5wt.% silver nanoparticles and 1wt.% silver nanoparticles were evenly dispersed in the PMMA matrix to prepare Ag / PMMA nanocomposites with different contents.

[0035] 2. Laminate 0.5wt%Ag / PMMA, 1wt.%Ag / PMMA and pure PMMA sheets, melt and hot press at 210°C to form a gradient composite material.

[0036] 3. Put the prepared gradient composite material in the autoclave, blow a small amount of carbon dioxide into the autoclave for 3 minutes, then raise the temperature of the autoclave to 50°C, and then use a syringe pump to inject carbon dioxide to reach 12MPa, and saturate at constant temperature and pressure for 6h to obtain Gradient Composite Materials Saturated by Carbon Dioxide Adsorption.

[0037] 4. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, remove the heating device after 180s, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

[0038] The cell structure of the cell gra...

specific example 3

[0040] 1. 1wt.% silver nanoparticles and 1wt.% carbon nanotubes were evenly dispersed into PMMA matrix to prepare Ag / PMMA and CNTs / PMMA nanocomposites.

[0041] 2. Laminate CNTs / PMMA, Ag / PMMA and pure PMMA sheets, melt and hot press at 210°C to form a gradient composite material.

[0042] 3. Put the prepared composite material in the autoclave, blow it with a small amount of carbon dioxide for 3 minutes, then raise the temperature of the autoclave to 65°C, and then use a plug pump to inject carbon dioxide to reach 7.5MPa, and saturate at constant temperature and pressure for 6h, to obtain Gradient Composite Materials Saturated by Carbon Dioxide Adsorption.

[0043] 4. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, remove the heating device after 10 seconds, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

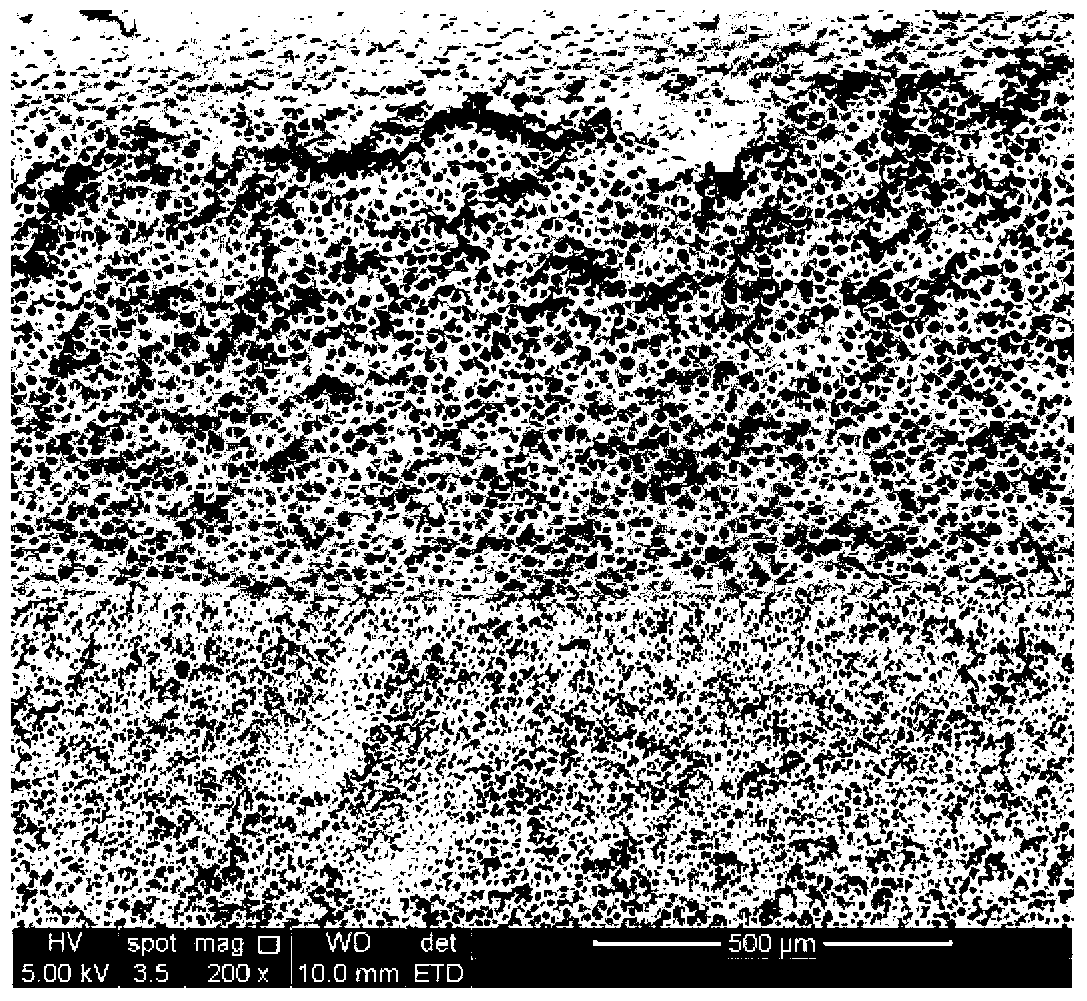

[0044] The cell structure of the cell gradient material is as follows image 3 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com