Lightweight high-strength ceramsite and preparation method thereof

A technology of high-strength ceramsite and preparation process, applied in the field of light-weight and high-strength ceramsite, can solve the problems of low added value, high cost, land occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

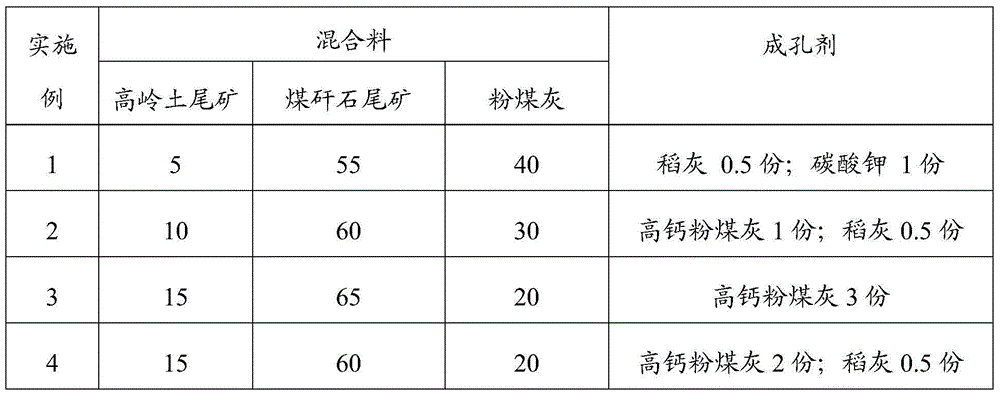

[0017] A light-weight high-strength ceramsite, including a mixture and a pore-forming agent with a mass ratio of 100:1.5-3;

[0018] Described compound comprises each component of following parts by weight:

[0019] 5-15 parts of kaolin tailings, 55-65 parts of coal gangue and 20-40 parts of fly ash.

[0020] The pore-forming agent is a mixture of one or more of carbonates, rice ash, high-calcium fly ash, etc. in any proportion.

[0021] In order to describe the present invention better, special enumerate following embodiment:

[0022]

[0023] The preparation technology of described lightweight high-strength ceramsite, comprises the following steps:

[0024] (1) kaolin tailings, coal gangue, and fly ash are mixed, ground, and passed through a 0.16mm sieve to obtain a mixture;

[0025] (2) Add a pore-forming agent into the mixture, mix evenly, add water to stir and shape to the required size to obtain ceramsite raw material;

[0026] The pore-forming agent is a mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com