Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

A technology of aluminum-based silicon carbide and composite materials, which is applied in the direction of electrical components, circuits, and electrical solid devices, can solve the problems of uneven mixing, large surface, and uneven distribution of reinforcement phases, and achieve good thermal conductivity and reduce packaging quality. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Preparation of Graphene Reinforced AlSiC Composites for Electronic Packaging

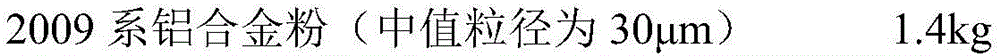

[0071] The composition of the graphene-enhanced aluminum silicon carbide electronic packaging composite material is:

[0072]

[0073]

[0074] The preparation method of graphene reinforced phase aluminum silicon carbide electronic packaging composite material comprises the following steps:

[0075] 1. Uniformly disperse 1000g graphene into 1000ml absolute ethanol solution by ultrasonic (ultrasonic frequency 50Hz, ultrasonic 40min) to prepare graphene ethanol dispersion;

[0076] 2. Weigh 1.4kg of aluminum alloy powder and 1.3kg of silicon carbide, put them into the mixer in turn, mix at 500rpm for 30min; mix at 850rpm for 1h, and obtain a homogeneously mixed aluminum-silicon carbide powder;

[0077]3. Under the condition of 900rpm, atomize and spray 30ml of graphene ethanol dispersion into the prepared aluminum silicon carbide uniform mixed powder, and then mix at 900rpm f...

Embodiment 2

[0082] Example 2 Preparation of Graphene Reinforced AlSiC Composites for Electronic Packaging

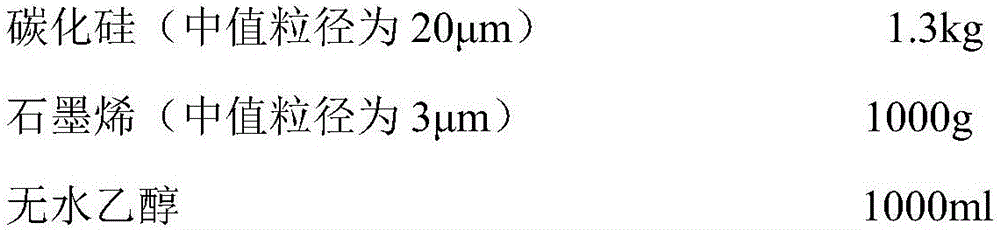

[0083] The composition of the graphene-enhanced aluminum silicon carbide electronic packaging composite material is:

[0084]

[0085]

[0086] The preparation method of graphene reinforced phase aluminum silicon carbide electronic packaging composite material comprises the following steps:

[0087] 1. Uniformly disperse 1000g graphene into 1000ml absolute ethanol solution by ultrasonic (ultrasonic frequency 70Hz, ultrasonic 35min) to prepare graphene ethanol dispersion;

[0088] 2. Weigh 1.3kg of aluminum alloy powder and 1.65kg of silicon carbide, put them into the mixer in turn, mix at 600rpm for 1h; after mixing at 950rpm for 2h, a uniform aluminum-silicon carbide mixed powder is obtained;

[0089] 3. Under the condition of 950rpm, atomize and spray 45ml of graphene ethanol dispersion into the prepared aluminum silicon carbide uniform mixed powder, and then mix for 2 h...

Embodiment 3

[0093] Example 3 Preparation of Graphene Reinforced AlSiC Composites for Electronic Packaging

[0094] The composition of the graphene-enhanced aluminum silicon carbide electronic packaging composite material is:

[0095]

[0096] The preparation method of graphene reinforced phase aluminum silicon carbide electronic packaging composite material comprises the following steps:

[0097] 1. Uniformly disperse 1000g graphene into 1000ml absolute ethanol solution by ultrasonic (ultrasonic frequency 80Hz, ultrasonic 35min) to prepare graphene ethanol dispersion;

[0098] 2. Weigh 1kg of aluminum alloy powder and 1.95kg of silicon carbide, put them into the mixer in turn, mix at 600rpm for 1h; after mixing at 1000rpm for 2h, a homogeneously mixed aluminum-silicon carbide powder is obtained;

[0099] 3. Under the condition of 1000rpm, atomize and spray 30ml of graphene ethanol dispersion into the prepared aluminum silicon carbide uniform mixed powder, and then mix at 1000rpm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com