Non-mulching-film well pit type cured tobacco young seedling transplanting method

A technology of transplanting seedlings and plastic film wells, applied in fertilization methods, botany equipment and methods, horticulture, etc., can solve the problems of time-consuming and labor-consuming, slow progress, etc., to shorten the time of seedling cultivation, reduce the cost of seedling cultivation and investment in facilities, Improve the effect of comprehensive utilization benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In 2011, Songtao County and Yinjiang County, Tongren District, Guizhou Province, used the method of the present invention to demonstrate a total area of 50 acres, and the effect was obvious. The specific approach is:

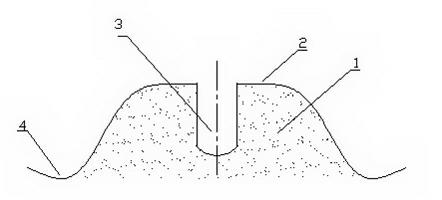

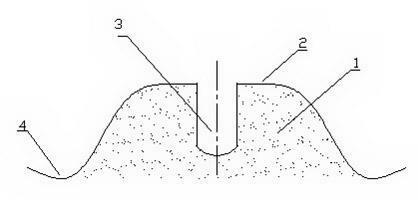

[0028] First carry out land preparation and ridging: 20 days before transplanting, do the land preparation and ridging, and apply the retting farm manure and special base fertilizer strips to the bottom of the ridge. The width of the bottom of the ridge is 70~80㎝ and the height is 25~30㎝. The ridge body is full and the ridge surface is finely broken.

[0029] Next, a cloudy day with a stable temperature of 13°C was selected as the best transplanting period for tobacco seedlings, and the best transplanting period for Tongren area was April 15-30.

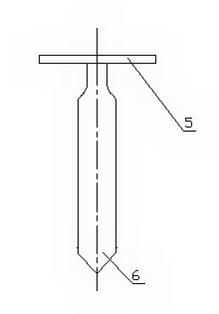

[0030] After that, make the transplanting well cellar. Before transplanting tobacco seedlings, press the determined transplanting plant spacing in the middle of the ridge, and use the punch tool to make the transpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com