Flue-cured tobacco mulch pyramidic hole transplanting method and structure after flue-cured tobacco mulch pyramidic hole field-planting

A square cone, plastic film technology, applied in the field of tobacco planting science, can solve the problems of time-consuming and labor-intensive transplanting of tobacco seedlings, time-consuming and labor-intensive problems of planting large nests, time-consuming and labor-intensive problems of small arched sheds, etc. The effect of small seedlings and reduction of transplanting labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

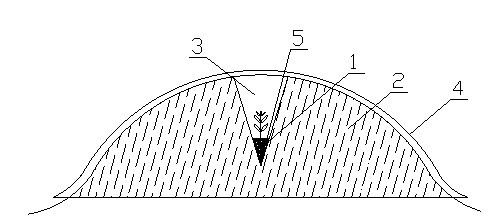

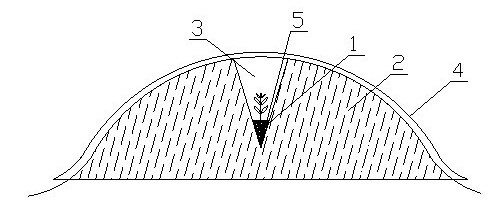

[0034] Example: as figure 1 Shown, planting of the present invention comprises the following steps

[0035] 1. Seedling operation

[0036] 1. For the seedling cultivation of tobacco seedlings, conventional floating seedling trays are used for seedling cultivation;

[0037] 2. Standards for transplanting seedlings: age of seedlings is 45-50 days; the stems are light green, with a circumference of about 1.5cm and a height of 4-5cm; the number of leaves is 5-6, and the leaf color is light green; no pests and diseases; take tobacco seedlings Tobacco seedlings with matrix that do not disperse from the root matrix 1 .

[0038] 2. Field operations

[0039] 1. Base fertilizer application: base fertilizer is applied to the bottom of the ridge before ridge formation;

[0040] 2. Ridging: Ridge 2 is raised 10-20 days before transplanting, the height of ridge 2 is 25-30 cm, the ridge body is straight and full, and the soil on the ridge surface is flat and fine;

[0041] 3. Punching:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com