Manufacturing method of bent bamboo furniture and bent bamboo rod pieces

A production method and a bending technology, which are applied in the direction of wood bending, manufacturing tools, wood processing appliances, etc., can solve the problems of low productivity of bent bamboo rods and bent bamboo boards, unsuitable molding process, etc., so as to save raw materials and not easily Molded deformation, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

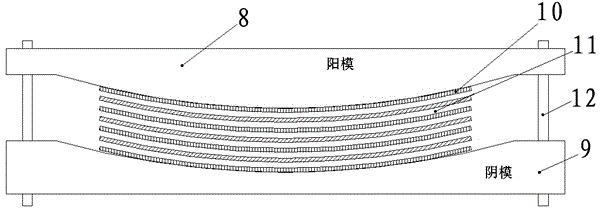

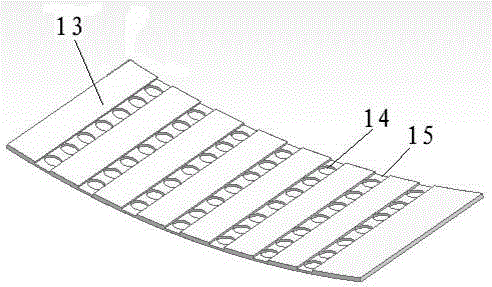

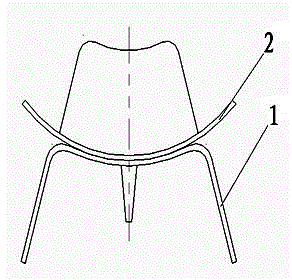

[0050] The accompanying drawings show a specific embodiment of the present invention, as can be seen from the accompanying drawings, the present invention relates to a production method of curved bamboo furniture, including the production of curved bamboo rods 1 and curved bamboo boards 2, as shown in the attached figure 1 Shown; Wherein, curved bamboo bar part 1 is made according to the following method:

[0051] Bamboo materials (such as Moso bamboo, Cizhu, etc.) are decomposed into long strips of bamboo filaments or bamboo strips with triangular or rectangular cross-sections after removing bamboo green and bamboo yellow that affect the bonding performance; then the strips of bamboo filaments or bamboo strips are dried to The moisture content is 8-15%; then use the method of spraying glue or dipping glue to apply adhesive to the surface of bamboo silk or bamboo strips; It is 20-30MPa. After the pre-compression is completed, the slabs are stacked layer by layer and placed in ...

Embodiment 2

[0065] Embodiment 2 is basically the same as Embodiment 1, except that the adhesive used for the curved bamboo rod and the curved bamboo board is a phenolic resin adhesive, so the heating and curing temperature of the curved bamboo rod slab is 125-135 ° C; the curved bamboo board is as follows The adhesive used in the preparation of the above method is a phenolic resin adhesive, so the temperature for thermal curing of the curved bamboo slab is 125-135°C.

[0066] It can be seen from the above embodiments that the present invention relates to a production method of curved bamboo furniture, including the production of curved bamboo rods and curved bamboo boards, wherein the curved bamboo rods are manufactured according to the following method:

[0067] Bamboo materials (such as Moso bamboo, Cizhu, etc.) are decomposed into long strips of bamboo filaments or bamboo strips with triangular or rectangular cross-sections after removing bamboo green and bamboo yellow that affect the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com