Preparation and using methods of ultra-infiltrating strain-resistant stainless steel fiber felt for emulsion separation

A technology of emulsion separation and stainless steel, applied in the direction of anodic oxidation, nanotechnology, etc., can solve the problems of unfavorable large-scale production and application, expensive reagents, complicated preparation process, etc., to improve the anti-dynamic droplet penetration pressure and anti-static The ability of liquid column pressure, the effect of improving anti-fouling and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

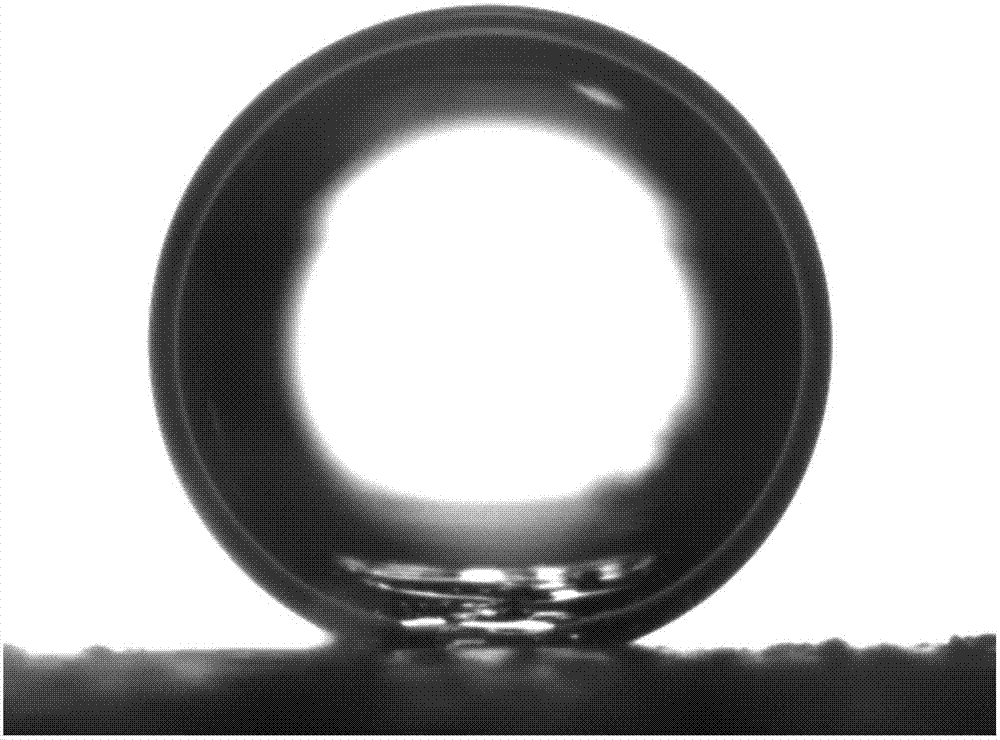

[0027] A method for preparing a super-wetting and stain-resistant stainless steel fiber felt for emulsion separation according to the present invention, the method comprises first adopting double anode electroplating to realize the coating of micron-sized copper particles on the surface of the stainless steel fiber, and then adopting electrochemical oxidation to obtain micronized copper hydroxide Nanoscale composite structures. Specific steps are as follows:

[0028] 1. Sample pretreatment: Cut the stainless steel fiber felt into small pieces of the required size, ultrasonically clean them with acetone for 10 minutes, wash them with absolute ethanol and deionized water for 5 minutes each, take them out, and dry them.

[0029] 2. Double anode copper plating: prepare 0.2~0.8mol / L CuSO 4 ·5H 2 O, 1.0~1.5mol / L H 2 SO 4 , 0.02-0.05g / L chloride ion and 0.03-0.06g / L polyethylene glycol (2000-10000) acidic electroplating solution, placed in the electroplating tank. Place the pret...

Embodiment example 1

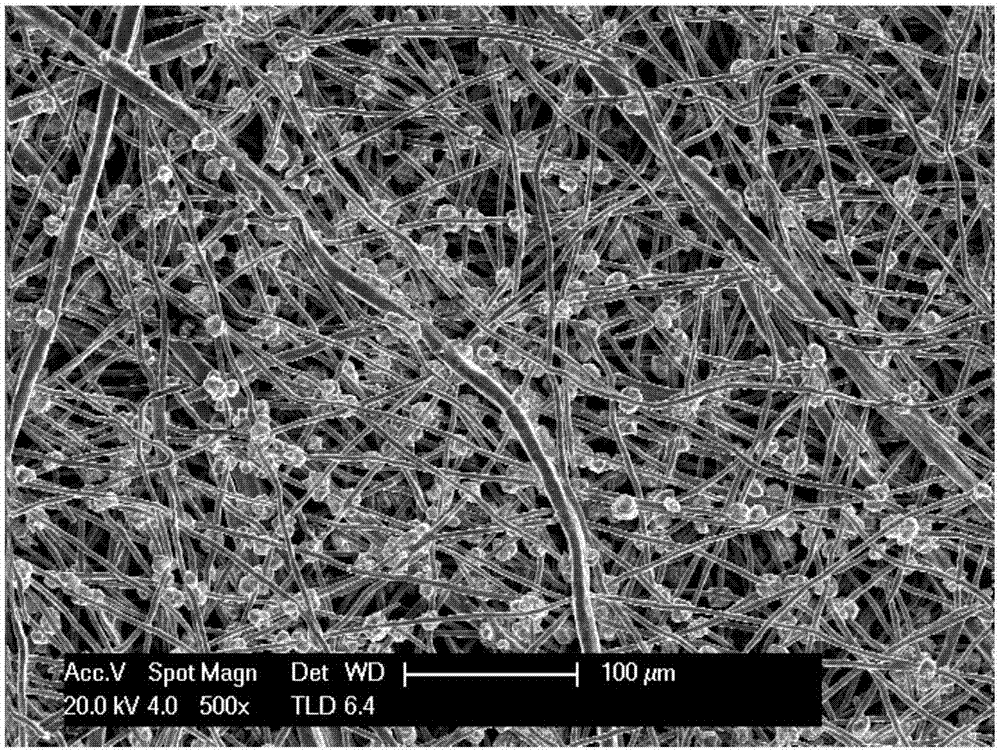

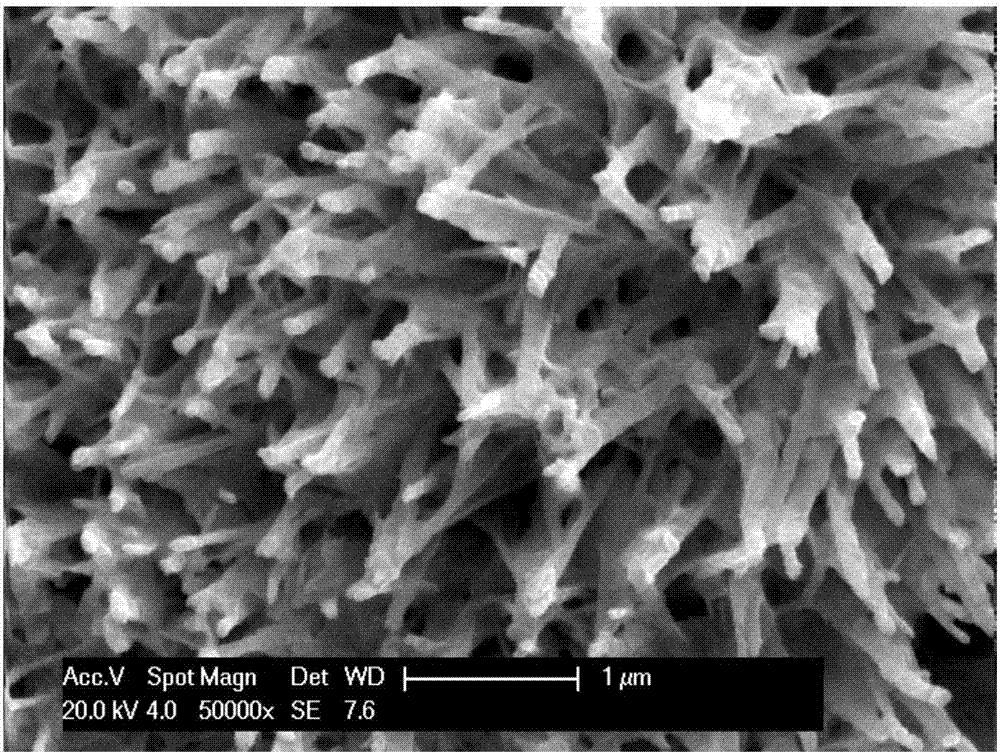

[0032] Cut the stainless steel fiber felt into small pieces of 5cm×5cm, first use acetone to ultrasonically clean it for 10 minutes, then wash it with absolute ethanol and deionized water for 5 minutes respectively, take it out and dry it. The scanning electron microscope photos of the cleaned stainless steel fiber felt are as follows: figure 1 shown. Prepare 0.8mol / L CuSO 4 ·5H 2 O, 1.1mol / L H 2 SO 4 , 0.02g / L chloride ion and 0.03g / L polyethylene glycol mixed aqueous solution is placed in the electroplating tank. The pretreated stainless steel felt is used as the cathode, and two pure copper sheets of the same size are used as the anode, and the distance between the cathode and the anode is 5cm, placed in the electroplating tank, and the constant current density is 80mA / cm 2 , electroplating 10min. After electroplating, the samples were taken out, washed with ethanol and deionized water, and dried in an oven at 50°C. After electroplating, micron-sized copper particles...

Embodiment example 2

[0034] Cut the stainless steel fiber mat into small pieces of 5cm×5cm, first use acetone to ultrasonically clean it for 10 minutes, then wash it with absolute ethanol and deionized water for 5 minutes respectively, take it out and dry it. Prepare 0.5mol / L CuSO 4 ·5H 2 O, 1.2mol / L H 2 SO 4 , 0.04g / L chloride ion and 0.05g / L polyethylene glycol mixed aqueous solution, placed in the electroplating tank. The pretreated stainless steel fiber felt is used as the cathode, and two pure copper sheets of the same size are used as the anode, and the distance between the cathode and the anode is 3cm, placed in the electroplating tank, and the constant current density is 40mA / cm 2 , Plating 0.5h. After electroplating, the samples were taken out, washed with ethanol and deionized water, and dried in an oven at 50°C. Configure 1mol / L NaOH aqueous solution. At room temperature, the electroplated and activated stainless steel fiber felt is used as the anode, and two pure copper sheets of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com