Box-type vacuum and atmosphere medium-frequency induction sintering furnace and using method

An induction sintering and vacuum technology, which is applied in the field of atmospheric medium frequency induction sintering furnace and box vacuum, can solve the problems of easy deformation, inconvenient processing and manufacturing, and inability to meet a large number of slab sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

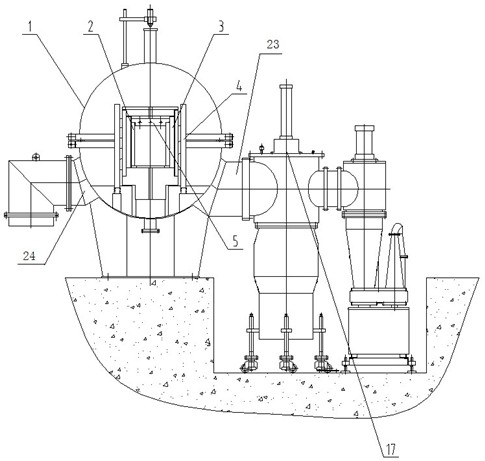

[0027] In order to overcome the problems that the existing vertical circular structure sintering furnace has a low space utilization rate during slab sintering, the slab is easily deformed during the sintering process, and it is not convenient for subsequent processing and manufacturing, the present invention provides such figure 1 A box-type vacuum and atmosphere medium-frequency induction sintering furnace is shown. By adopting a box-type structure furnace, the present invention places the sintered tungsten-molybdenum slab products horizontally on the discharge bottom support, and improves the bending of the sintered material to the greatest extent. Deformation, reducing the straightening and leveling process of tungsten and molybdenum products, and reducing production costs.

[0028] like figure 1 , figure 2 As shown, a box-type vacuum and atmosphere medium-frequency induction sintering furnace includes a furnace shell 1, a furnace core assembly located inside the furnace...

Embodiment 2

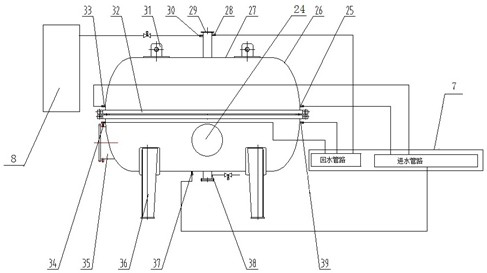

[0031] Preferably, on the basis of Embodiment 1, in this embodiment, the furnace shell 1 is a horizontal circular double-layer water-cooling jacket structure, which is welded by the head 26, the cylinder body 27 and the flange 32, so that The central position of the cylinder 27 top of the furnace shell 1 is respectively provided with an observation window temperature measuring hole 29, an upper furnace body drain 28, and an air inlet 30, and the two sides of the cylinder 27 top of the furnace shell 1 are respectively provided with There are lifting lugs 31, and the two ends of the sealing head 26 are respectively provided with the upper furnace body water inlet I25 and the upper furnace body water inlet II33 near the upper part of the flange 32, and the two ends of the sealing head 26 are close to the lower part of the flange 32 The lower furnace body drain port I34 and the lower furnace body drain port II39 are respectively provided. The head 26 below the lower furnace body dr...

Embodiment 3

[0044] A method for using a box-type vacuum and atmosphere medium-frequency induction sintering furnace, using any one of the above-mentioned box-type vacuum and atmosphere medium-frequency induction sintering furnaces, the specific process is:

[0045] S1: put the material to be sintered into the uniform temperature zone of the intermediate frequency induction sintering furnace, cover the furnace top cover 5, and complete the charging of the box-type vacuum intermediate frequency induction sintering furnace;

[0046] S2: Turn on the intermediate frequency induction sintering furnace;

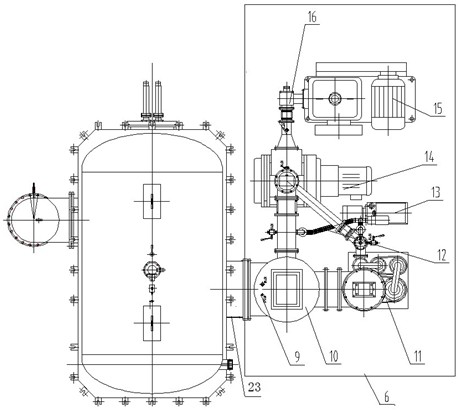

[0047] When vacuum sintering is selected as the working mode, the slide valve pump 15 is first turned on to evacuate the furnace shell 1, the oil increasing pump 11 and the diffusion pump 10; When the vacuum of the increase pump 11 and the diffusion pump 10 reaches 20Pa, turn on the heating power supply of the oil increase pump 11 and the diffusion pump 10 to heat the oil temperature in the pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com