Square heating body device of tungsten-molybdenum sintering furnace

A heating element and furnace square technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of high cost, small production capacity, large energy consumption, etc., and achieve the effects of low energy consumption, large production capacity, and reduced production consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

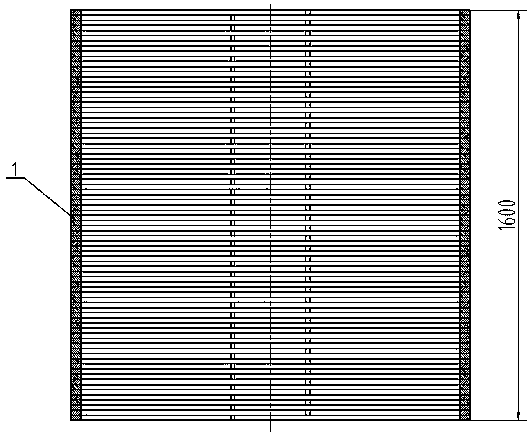

[0029] In order to overcome the existing problems of large energy consumption, small production capacity and high cost, the present invention provides such Figure 1-10 A square heating element device for a tungsten-molybdenum sintering furnace is shown. After changing the round heating element into a square heating element, the sintered tungsten and molybdenum products can be placed flat on the bottom support, which improves the maximum The bending deformation of the sintered material greatly reduces the straightening and leveling process of the tungsten and molybdenum products, and improves the product quality. The square heating element can increase the utilization rate of the furnace, with less energy consumption and large production capacity. The recovery rate of materials after the square heating element is scrapped can reach more than 70%, which can save a lot of valuable tungsten materials, greatly reduce production consumption and save production costs.

[0030] A sq...

Embodiment 2

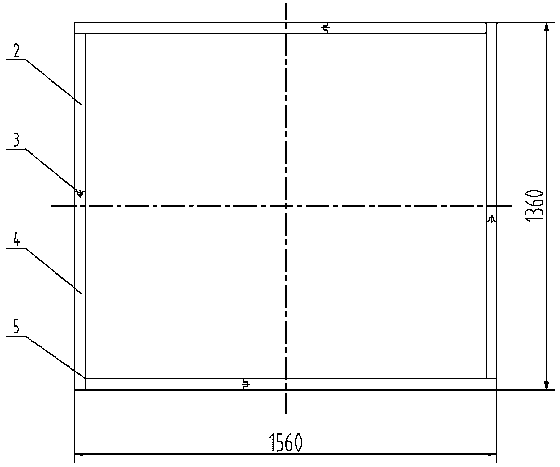

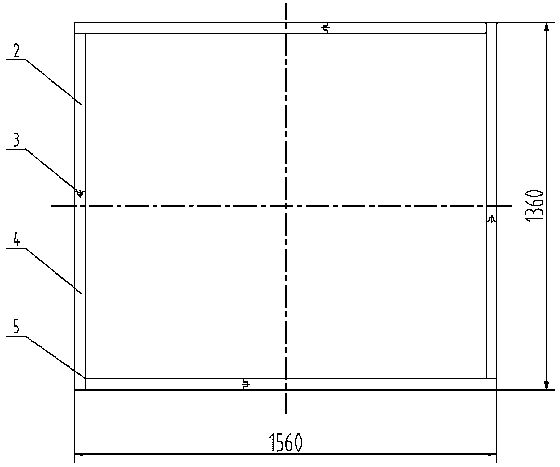

[0034] Based on Example 1, in this embodiment, the long tungsten bar 4 is longer than the short tungsten bar 2, and both the short tungsten bar 2 and the long tungsten bar 4 are cut from rolled tungsten plates.

[0035] The spigot 3 includes a convex slit 6 and a concave slit 7, the convex slit 6 and the concave slit 7 are respectively arranged on the long tungsten bar 4 and the short tungsten bar 2, and the two spigots are engaged, When the convex seam 6 and the concave seam 7 are engaged, an expansion joint is left.

[0036] The range of the expansion joint is 0.2-5mm.

[0037] In the present invention, the short tungsten bar 2 and the long tungsten bar 4 are engaged through the seam 3, and the seam 3 is divided into Figure 5 Shown male relief 6 and Figure 6 The concave stop 7, the convex stop 6 and the concave stop 7 should leave a certain amount of expansion joints when occlusal, so as to avoid the deformation of the tungsten strip when the induced magnetic field passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com