Square induction coil for 2500 DEG C tungsten-molybdenum sintering furnace

A technology for induction coils and sintering furnaces, which is applied to coil devices, induction heating, furnaces, etc., can solve the problems of low space utilization, low efficiency, and large energy consumption of circular coils, and achieve reduction in straightening and leveling processes and improvement The effect of product quality and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In order to overcome the problems of low space utilization rate of existing circular coils, large energy consumption and low efficiency during use, the present invention provides a square induction coil for 2500°C tungsten-molybdenum sintering furnace. The square induction coil provided by the present invention The utilization rate of the furnace can be increased, the energy consumption is small, and the production capacity is large.

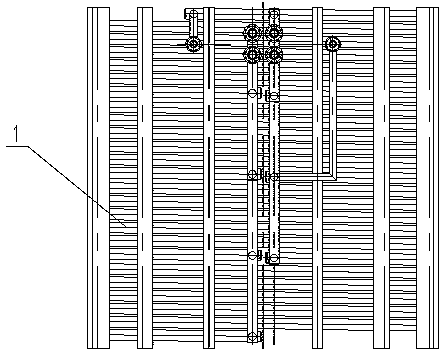

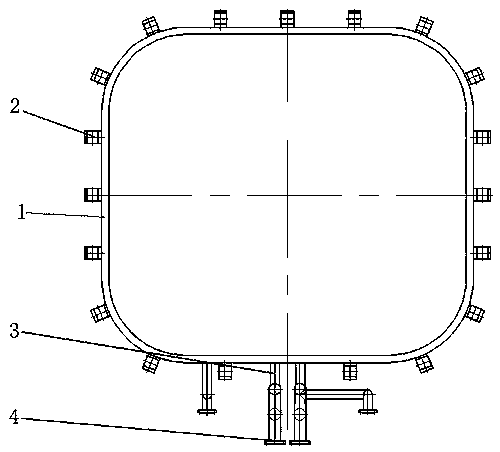

[0027] A square induction coil for a 2500°C tungsten-molybdenum sintering furnace, including a copper tube 1, a bakelite column 2, a lead-out electrode 3 and an electrode flange 4; the copper tube 1 is wound into a square coil shape, and the bakelite Columns 2 are evenly distributed on the outer surface of the copper pipe 1, the distance between two adjacent bakelite columns 2 is 240-560mm, the outer surface of the copper pipe 1 is provided with a lead-out electrode 3, and the lead-out electrode 3 is connected to the electrode flange 4; th...

Embodiment 2

[0032] On the basis of Embodiment 1, in this embodiment, the four corners around the coiled copper tube 1 wound into a square are copper tube rounded corners 7 .

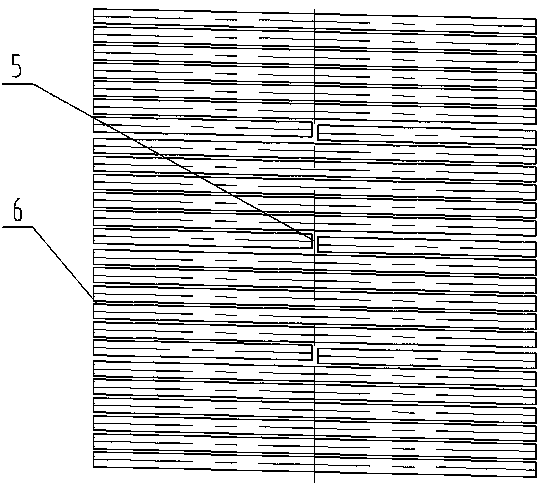

[0033] The copper tube turn spacing 5 of the copper tube 1 is 5-35mm.

[0034] The copper pipe 1 and the bakelite column 2 are fixed by copper studs.

[0035] The cooling water quality requirements: water inlet temperature ≤25±5°C, PH value between 6-9, resistivity 30×10³Ω.cm hardness not greater than 10 degrees, wherein 1 liter of water contains 10mg of oxidation Calcium, the total solid content does not exceed 250mg / L, and the outlet water temperature should be controlled below 45 degrees Celsius.

[0036] The square induction coil provided by the present invention is composed of a copper pipe 1 and a bakelite column 2 . Copper pipe 1 passes a special mold to make the section into Figure 8 The copper tubing shown is 1 wound into Figure 4 coil shape shown, and guarantees that during winding, Figure 8 The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com