Square-shaped tungsten molybdenum induction sintering furnace

An induction sintering and tungsten-molybdenum technology, which is applied in the field of square tungsten-molybdenum induction sintering furnaces, can solve the problems of easy deformation of slabs, low space utilization, and low efficiency, so as to reduce straightening and leveling procedures, reduce energy consumption, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

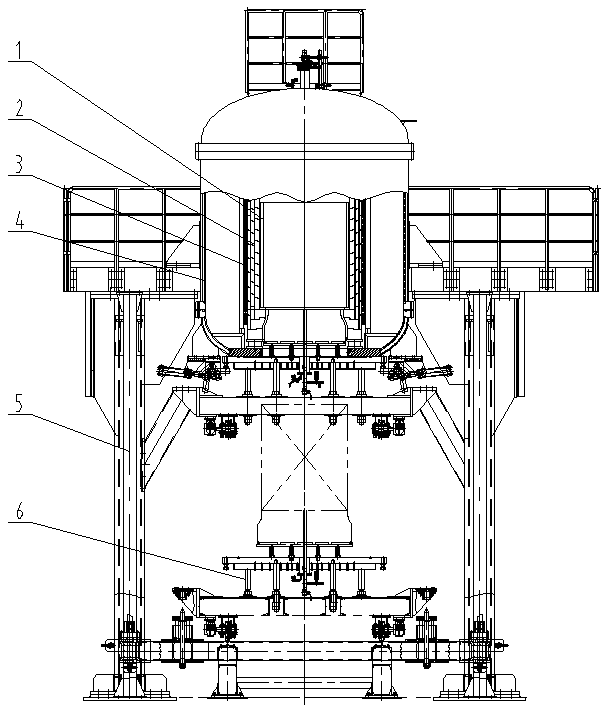

[0030] In order to overcome the problems of low space utilization, high energy consumption, low efficiency, high cost and easy deformation of the slab during the sintering process of the existing slab, the present invention provides such as Figure 1-8 A square tungsten-molybdenum induction sintering furnace is shown. In the present invention, the heating element, refractory device and induction coil all adopt a rectangular structure. This structure allows the sintered tungsten-molybdenum slab products to be placed horizontally on the bottom support. The bending deformation of the sintered material is improved to the greatest extent, the straightening and leveling process of tungsten and molybdenum products is greatly reduced, the production cost is reduced, and the influence of heating and pressure processing on the product quality during the calibration process is avoided.

[0031] A square tungsten-molybdenum induction sintering furnace, comprising a heating element 1, a ref...

Embodiment 2

[0035] Based on Embodiment 1, in this embodiment, the furnace body 4 is a cylindrical furnace body.

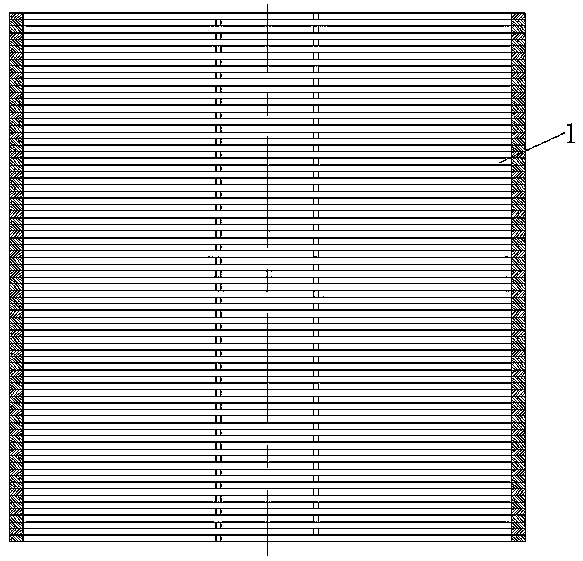

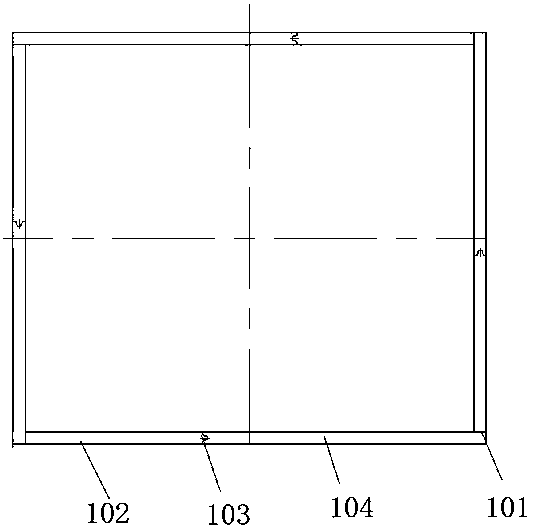

[0036] The material of the heating body 1 is made of tungsten products, and the heating body 1 is composed of a short tungsten bar 102, a seam 103 and a long tungsten bar 104; the short tungsten bar 102 is connected with the long tungsten bar 104 through the seam 103, and the short tungsten Strips 102 and long tungsten strips 104 are spliced to form a layer of square-shaped tungsten strips. The four corners of the square-shaped tungsten strips are the corners of the heating element 101. Each spliced tungsten strip is stacked layer by layer to form the heating element 1. The joints with the short tungsten bars 102 are staggered from each other; there is a gap of 5-25 mm between the heating element 1 and the refractory material 102 .

[0037] In the present invention, the spliced tungsten strips of each layer are stacked layer by layer to form a square heating element 1. W...

Embodiment 3

[0041] On the basis of Embodiment 1, in this embodiment, the induction coil 3 is at least composed of a copper tube 301, a Bakelite column 302, a lead-out electrode 303 and an electrode flange 304, and the copper tube 301 is wound into a coil shape, The bakelite columns 302 are evenly distributed on the outer surface of the copper pipe 301 wound into a coil shape and the copper pipe 301 is fixed; the copper pipe 301 and the electrode flange 304 are connected through the lead-out electrode 303; the induction coil 3 and the refractory device 2 There is an expansion joint of 5-30mm in between.

[0042] In the present invention, when the induction coil 3 is fixed by using the bakelite columns 302, the bakelite columns 302 are evenly distributed, and the spacing is between 240-560 mm, which ensures that the fixed induction coil 3 is stable and reliable. When the induction coil 3 is energized and heated, it needs to feed cooling water into the copper pipe 301. The quality requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com