Preparation method of graphical three-dimensional graphene/polyurethane flexible conductive film

A polyurethane flexible and conductive film technology, applied in cable/conductor manufacturing, carbon-silicon compound conductors, circuits, etc., can solve the problems of unstable excellent properties of structural graphene films, weak material tensile properties, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

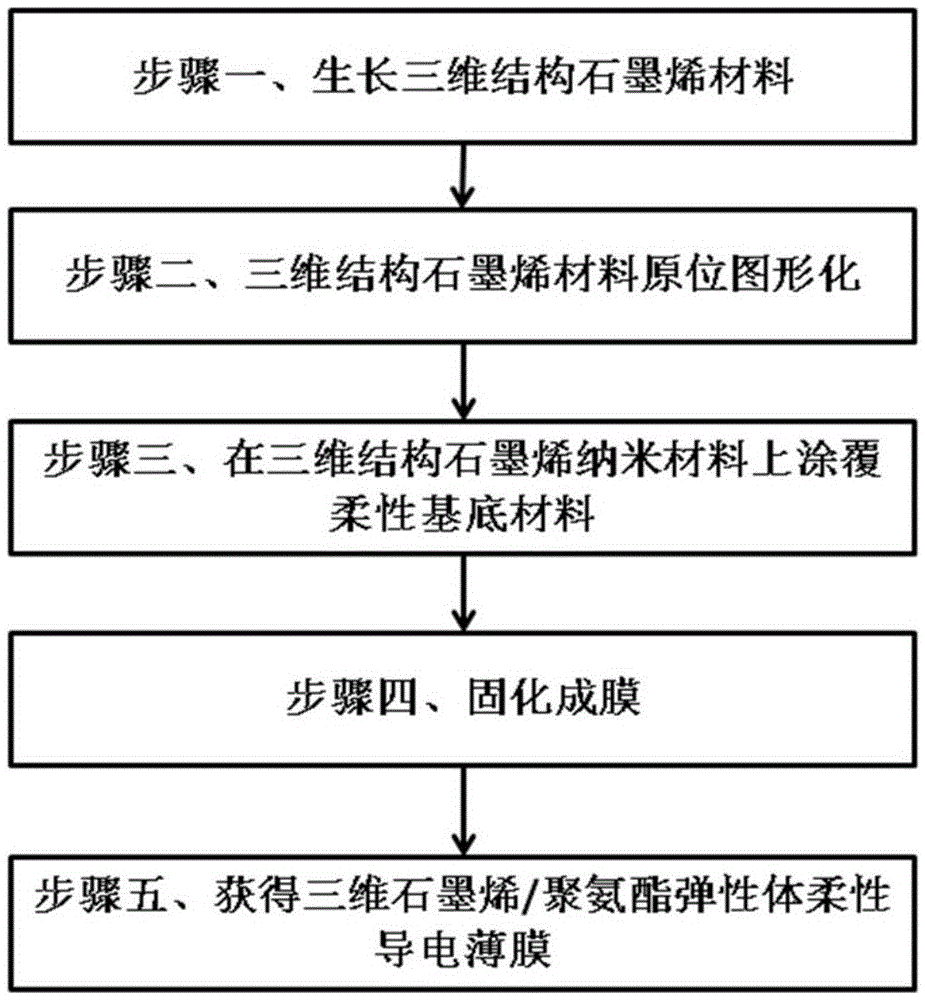

[0029] A kind of preparation method of patternable three-dimensional graphene / polyurethane flexible conductive film, the technological preparation process of this method is as follows figure 1 Specifically, the following steps are included:

[0030] Step 1, by CVD method on the growth substrate 1 such as figure 2 Three-dimensional structured graphene materials with different thicknesses were grown on 2 as shown image 3 shown.

[0031] Specific steps: place the growth substrate 1 of the graphene film in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 5 minutes, and dry it with nitrogen; put the pretreated growth substrate into the vacuum chamber of the tubular CVD system for Three-dimensional graphene growth, the growth conditions are normal pressure, temperature 750°C, hydrogen 15sccm, methane 22.5sccm, growth time 30min, and the number of graphene nanowalls obtained is 5-10 layers.

[0032] Step 2: In-situ patterning of the three-dimensional structure...

Embodiment 2

[0039] A kind of preparation method of patternable three-dimensional graphene / polyurethane flexible conductive film, the technological preparation process of this method is as follows figure 1 Specifically, the following steps are included:

[0040] Step 1, by PECVD method on the growth substrate 1 such as figure 2 Three-dimensional structured graphene materials with different thicknesses were grown on 2 as shown image 3 shown.

[0041] Specific steps: place the growth substrate 1 of the graphene film in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 10 minutes, and dry it with nitrogen; put the pretreated growth substrate into the vacuum chamber of the tubular PECVD system Three-dimensional graphene growth, the growth conditions are normal pressure, temperature 600°C, hydrogen gas 20 sccm, methane 30 sccm, growth time 60 min, and the number of graphene nanowall layers obtained is 10-20 layers.

[0042] Step 2: In-situ patterning of the three-dimensio...

Embodiment 3

[0049] A kind of preparation method of patternable three-dimensional graphene / polyurethane flexible conductive film, the technological preparation process of this method is as follows figure 1 Specifically, the following steps are included:

[0050] Step 1, by MPECVD method on the growth substrate 1 such as figure 2 Three-dimensional structured graphene materials with different thicknesses were grown on 2 as shown image 3 shown.

[0051] Specific steps: place the growth substrate 1 of the graphene film in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 10 minutes, and dry it with nitrogen; put the pretreated growth substrate into the vacuum chamber of the tubular MPECVD system Three-dimensional graphene growth, the growth conditions are normal pressure, temperature 600°C, hydrogen gas 20 sccm, methane 30 sccm, growth time 60 min, and the number of graphene nanowall layers obtained is 3-10 layers.

[0052] Step 2: In-situ patterning of the three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com