Wafer drying machine and implementation method

A realization method and wafer technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of wafer scratches, unqualified wafer surface quality, etc., and achieve the effect of rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

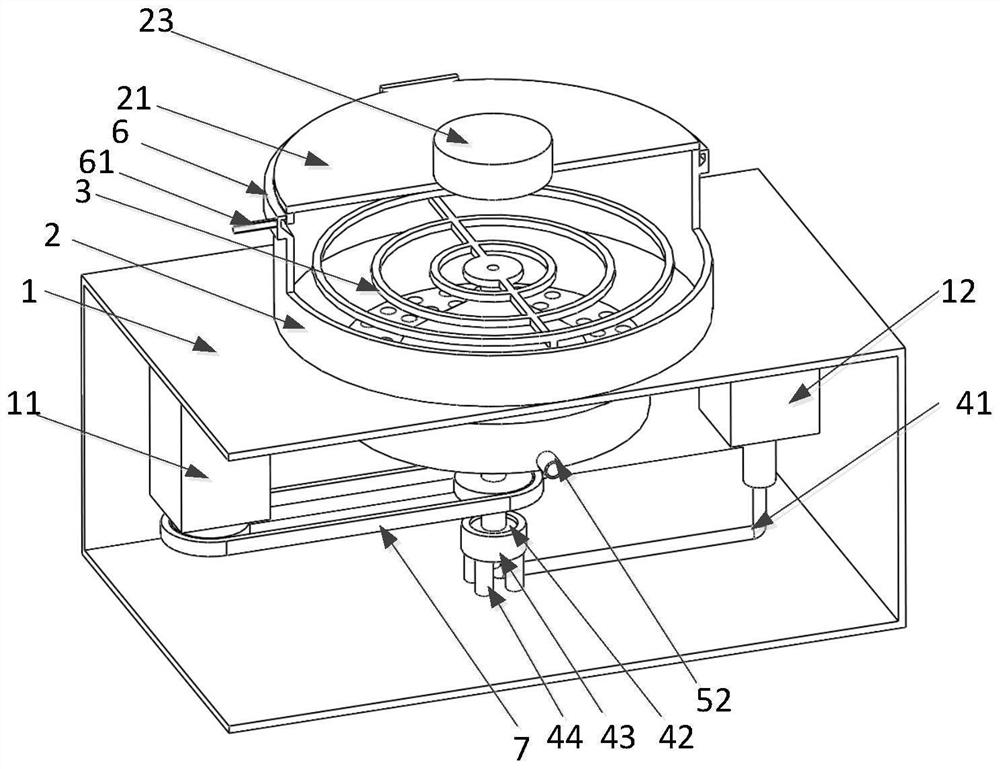

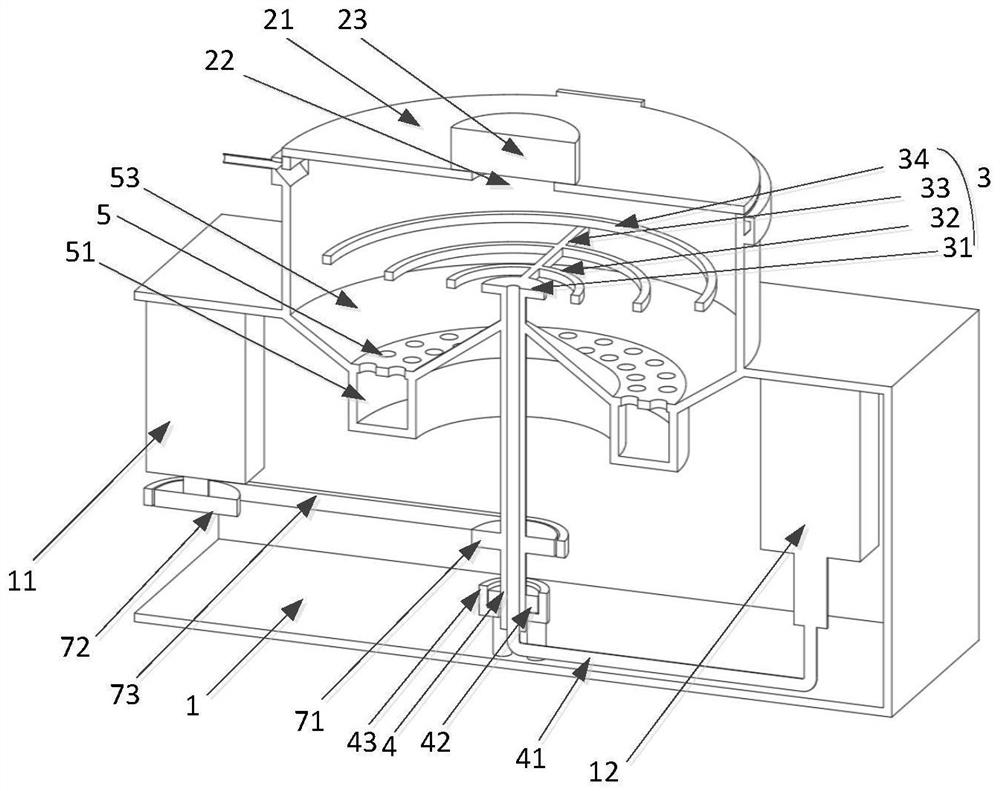

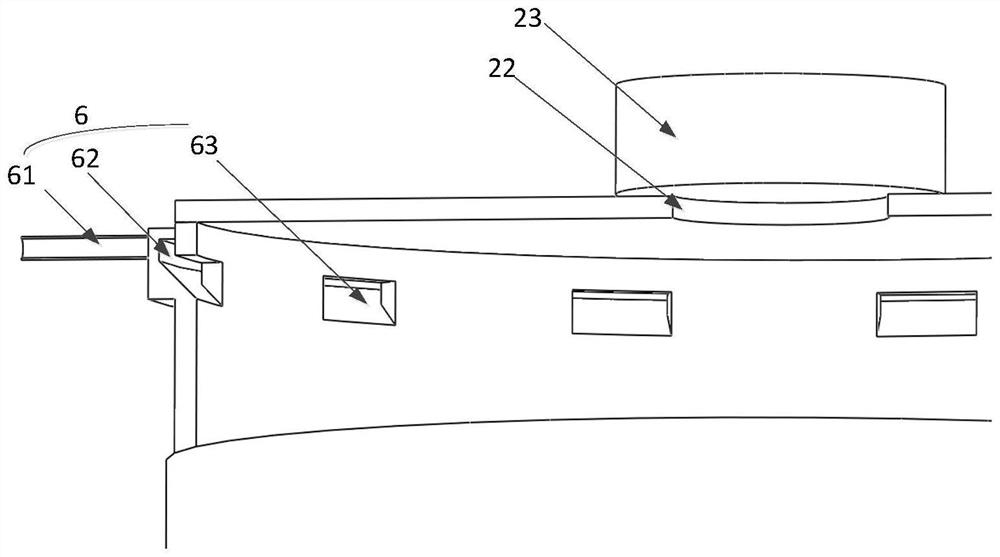

[0050] like Figure 1-2 As shown, a wafer drying machine includes a box body 1 and a barrel body 2 arranged on the top of the box body 1. A barrel cover 21 is hinged on the top of the barrel body 2, and a camera 23 with a lens facing downward is arranged in the middle of the barrel cover 21. The middle part of the cylinder body 2 is provided with a tray 3, the bottom of the tray 3 is connected with a rotating shaft 4, and the lower end of the rotating shaft 4 is rotatably connected to the bottom wall of the box body 1; the bottom of the cylinder body 2 is provided with a water outlet 5, and the bottom of the water outlet 5 is provided with a ring The water tank 51 is provided with a drainage pipe 52 on the water tank 51; the outer wall of the cylinder body 2 is provided with an annular air passage 6 that is conductive with the inner side of the cylinder body 2, and the air passage 6 is provided with a blowing pipe 61, and the blowing pipe 61 is connected with a blower; A power...

Embodiment 2

[0057] like Figure 4 As shown, a method for implementing a wafer spinner based on Embodiment 1 includes the following steps:

[0058] (1) Open the cylinder cover, place the wafer on the tray, and start the vacuum pump to adsorb the wafer;

[0059] (2) Close the cylinder cover, and start the power member to drive the shaft to rotate through the transmission assembly;

[0060] (3) Drive the tray to rotate through the rotating shaft, the wafer rotates with the drag tray, and the water droplets on the wafer are thrown onto the inner wall of the cylinder based on centrifugal force;

[0061] (4) The air is blown into the air path along the air blowing pipe by the blower, and the air is blown onto the wafer;

[0062] (5) The water droplets are introduced into the water tank through the water outlet hole and discharged through the drain pipe;

[0063] (6) When the preset time is reached, the power element and the blower are turned off, and the image data of the wafer is collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com