Dye-based ink and ink cartridge

A dye ink and dye technology, applied in the direction of ink, printing, household appliances, etc., can solve the problems of destroying dye chromophores, dye fading, easy plugging, etc., and achieves good film-forming gloss, film-forming strength, and good The effect of blocking the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

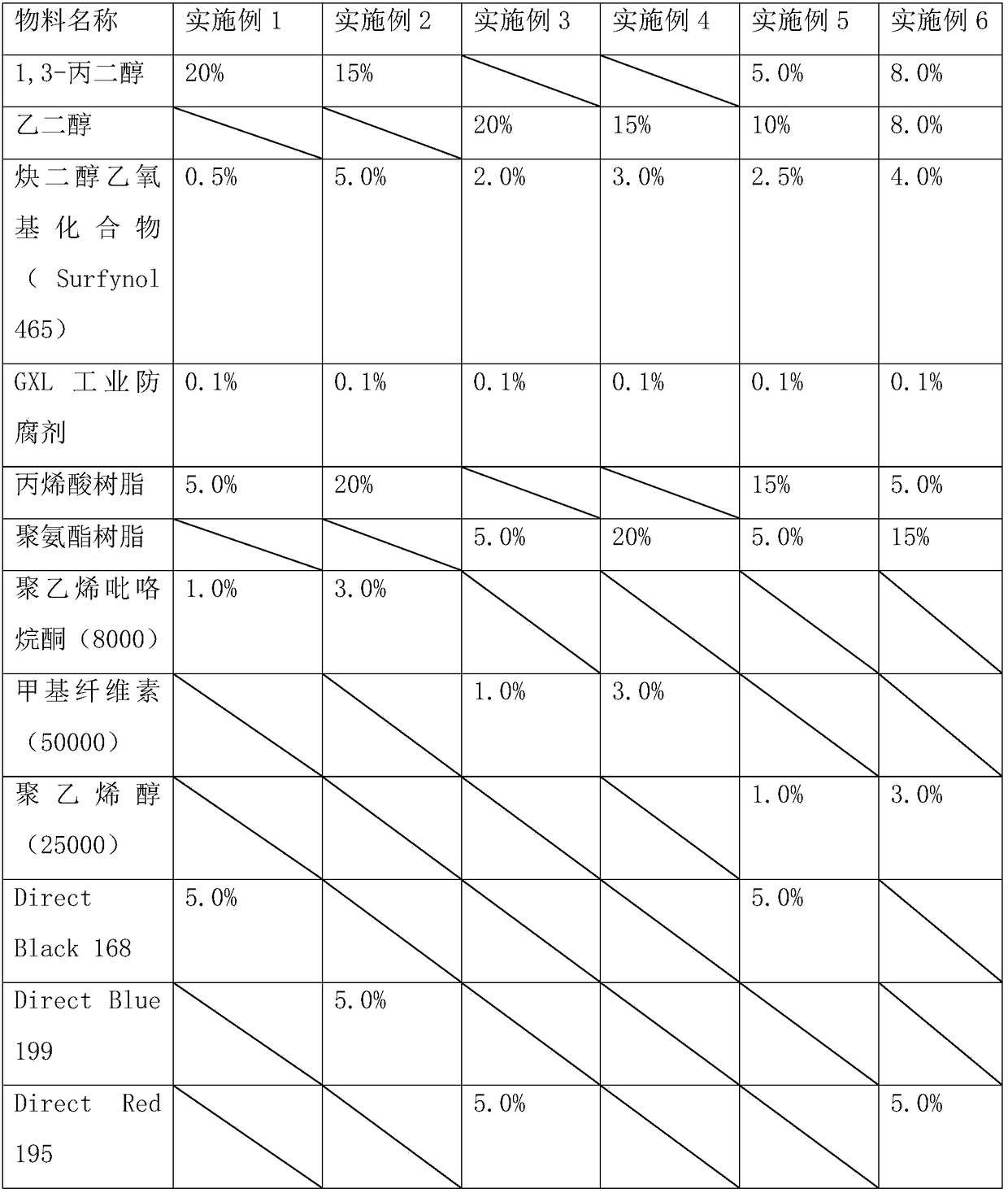

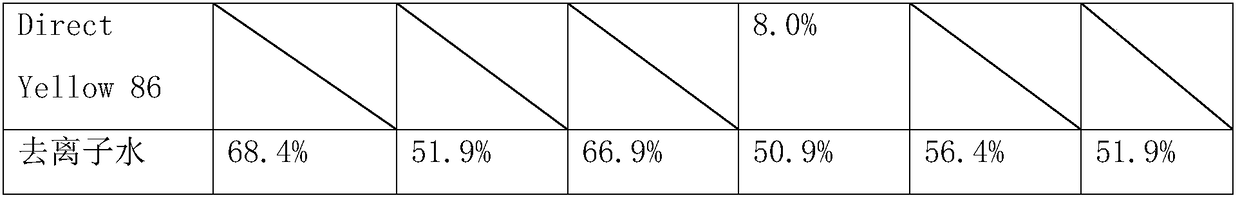

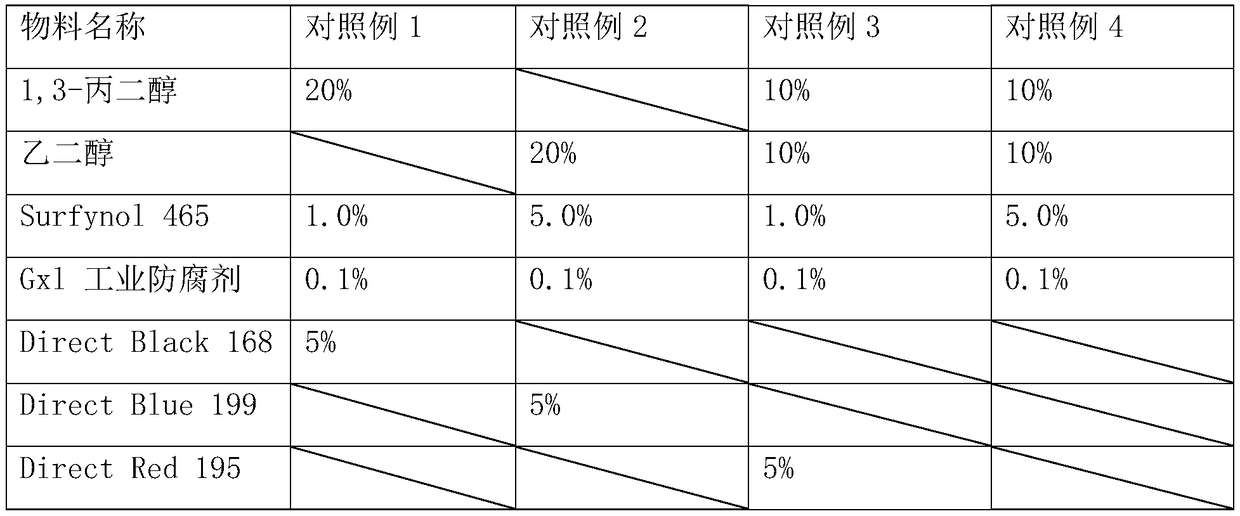

[0028] The formulations of Examples 1-6 are shown in Table 1.

[0029] Table 1

[0030]

[0031]

[0032] Among them, Surfynol 465 is Surfynol 465 Surfactant produced by American Air Chemical Company. GXL is the PROXELTM GXL industrial preservative produced by American Orin Company. The acrylic resin is Joncry HPD 96 produced by BASF D. BASF, Germany. The polyurethane resin is Takelac W-6355 produced by Mitsui Chemicals, Japan. The number average molecular weight of polyvinylpyrrolidone is 8,000, the number average molecular weight of methylcellulose is 50,000, and the number average molecular weight of polyvinyl alcohol is 25,000. The contents in Table 1 are all mass percentages (the same below).

Embodiment 1

[0033] The preparation method of the dye ink of Example 1: S1: Add 20% of 1,3 propylene glycol and 68.4% of deionized water to the container and mix, then add 0.5% of surfactant Surfynol 465, and then add 0.1% of GXL For industrial preservatives, place the container on a magnetic stirrer and stir at a speed of 160 revolutions per minute to 250 revolutions per minute. Wait until the solution is stirred until it becomes clear. S2: Add 5.0% acrylic resin and 1.0% polyvinylpyrrolidone to the container, and continue to stir the solution until it is clear. S3: Add 5% Direct Black 168 to the container, and after stirring for 1 hour, filter with a vinylidene fluoride membrane with a pore size of 1.2 μm to prepare a black dye ink 1.

[0034] Fill the prepared dye ink 1 into the printer EPSON STULUS PHOTO T50 ink cartridge and set it aside.

[0035] With reference to the preparation method of Example 1, the dye inks 2, 3, 4, 5, and 6 of Examples 2-6 were prepared and filled into the EPSON S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com