A kind of high-toughness environment-friendly peelable glue and preparation method thereof

An environmentally friendly, high-toughness technology, used in epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problems of poor impact resistance and vibration resistance, difficult to degrade, easy to crack, etc., to achieve a wide range of applications, film forming. Good strength and small elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

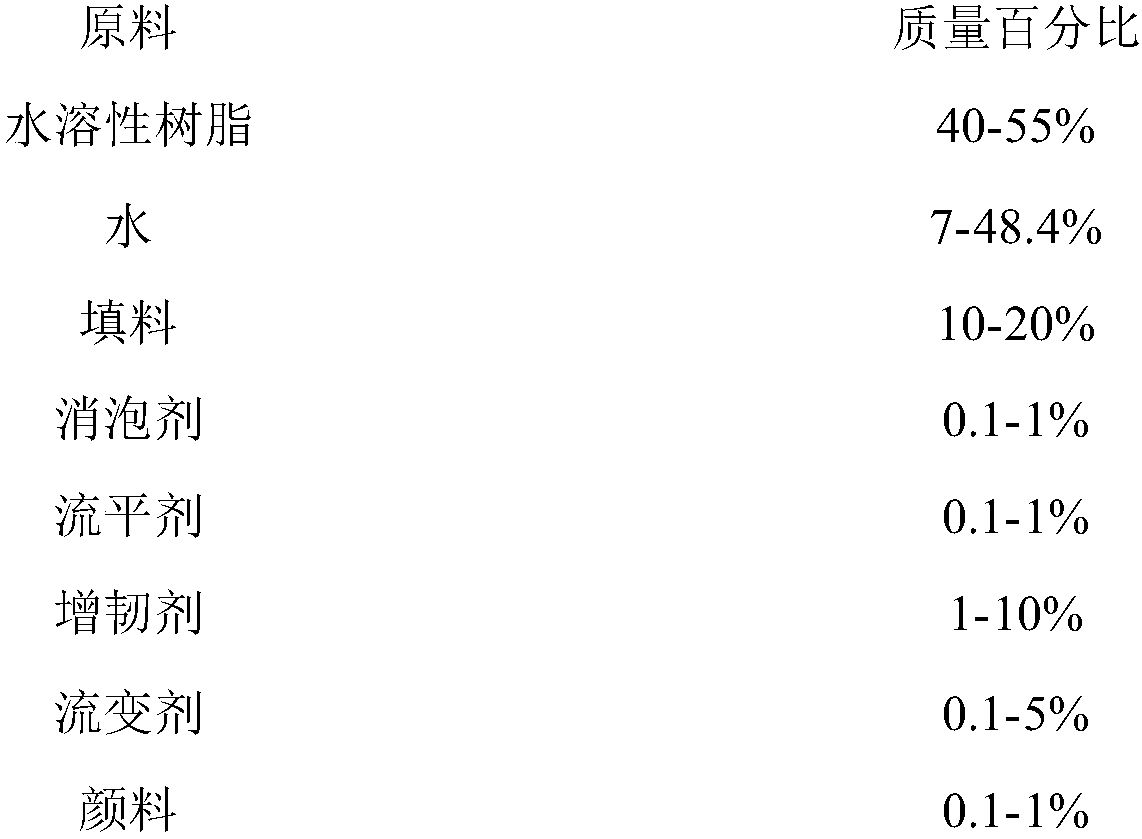

[0028] A high-toughness environment-friendly peelable rubber, which is prepared from the following raw materials (measured per 100kg of peelable rubber produced):

[0029] raw material

Dosage(kg)

Waterborne Polyacrylic Resin

40

water

48.4

10

Polyether type defoamer

0.3

Polyacrylic leveling agent

0.1

Carboxylated nitrile rubber

1

rheological agent

0.1

Phthalocyanine blue

0.1

[0030] The sources of raw materials used are as follows: the water-soluble resin is Korean Hanwha water-based polyacrylic acid solid resin, the model is Soluryl-160; the defoamer is the polyether defoamer of Wancheng Group, the model is XWC-753N; It is the product of Shanghai Dapan Chemical Co., Ltd., the model is DP-260; the carboxylated nitrile rubber is the product of Saikede Rubber and Plastic Company, the model is LR-899; the rheological agent is silica, Cabot silica TS- 720.

[0031] ...

Embodiment 2

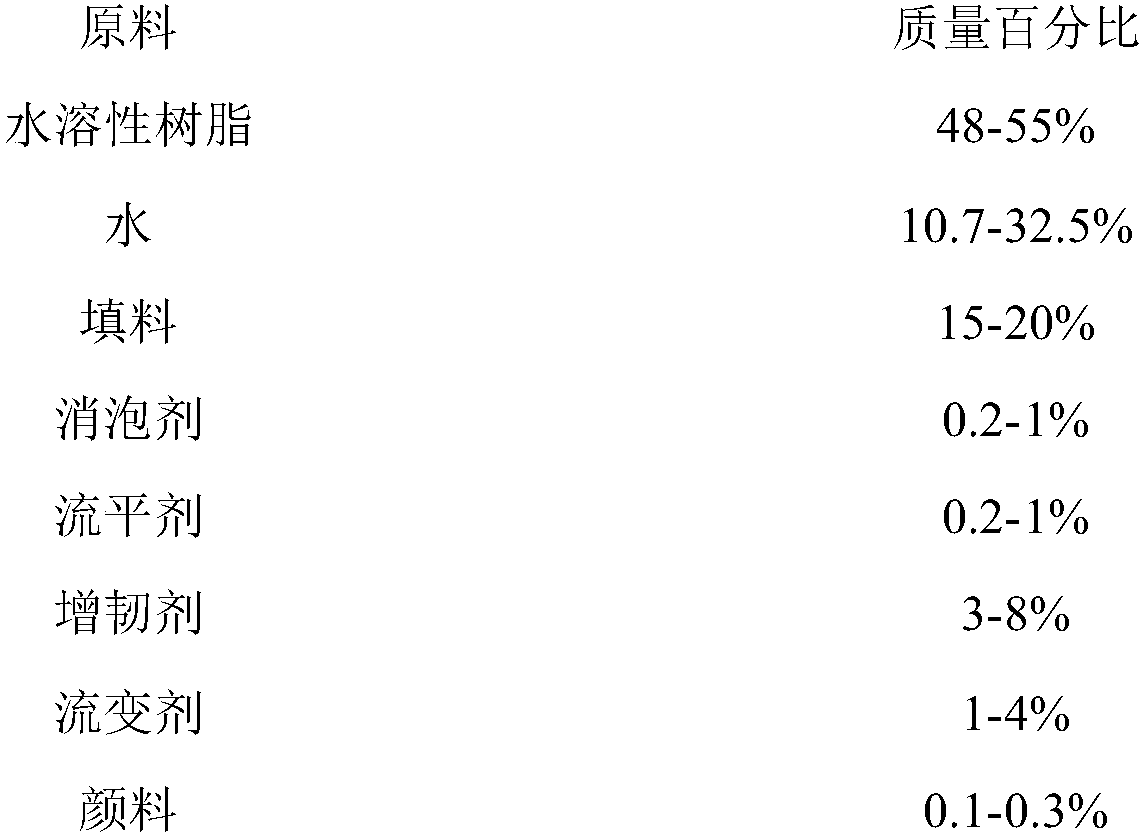

[0036] A high-toughness environment-friendly peelable rubber, which is prepared from the following raw materials (measured per 100kg of peelable rubber produced):

[0037]

[0038]

[0039] The sources of the raw materials used are as follows: the water-based epoxy resin is the product of Guangzhou Hongyu Trading Co., Ltd., the model is HY-100; the silicone defoamer is the product of Guangzhou Yuheng Chemical Materials Co., Ltd., the model is Y-698 / 699; The acrylic leveling agent is the product of Shanghai Dapan Chemical Co., Ltd., the model is DP-260; the carboxylated nitrile rubber is the product of Saikede Rubber and Plastic Company, the model is LR-899; the rheological agent is white carbon black, Cabot Silica TS-720.

[0040] The preparation method of the above-mentioned high-toughness environment-friendly peelable adhesive comprises the following steps:

[0041] (1) Take each component in proportion,

[0042] (2) Water-based epoxy resin is dissolved in part of wa...

Embodiment 3

[0045] A high-toughness environment-friendly peelable rubber, which is prepared from the following raw materials (measured per 100kg of peelable rubber produced):

[0046] raw material

Dosage kg

Waterborne polyurethane resin

55

water

7

20

Polyether type defoamer

1

Polyacrylic leveling agent

1

10

rheological agent

5

Phthalocyanine blue

1

[0047] The sources of raw materials used are as follows: water-based polyurethane resin is the product of Dongguan Mirenzhan Chemical Co., Ltd., model is MR-701; polyether type defoamer is the product of Weifang Dadong Chemical Co., Ltd., model is DEFOAMER NXZ; The leveling agent is the product of Shanghai Dapan Chemical Co., Ltd., the model is DP-260; the polyvinyl alcohol is the product of Beijing Guohao Chemical Company, the model is GH-JY; the rheological agent is white carbon black, Cabot White Carbon Black TS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com