A kind of graphene conductive thermal conductive coating and preparation method thereof

An electrical and thermal conductivity, graphene technology, applied in the field of materials, can solve the problems of low service life, poor bonding performance between paint and substrate, low electrical and thermal conductivity, etc., and achieves good anti-rust performance, high bonding strength, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

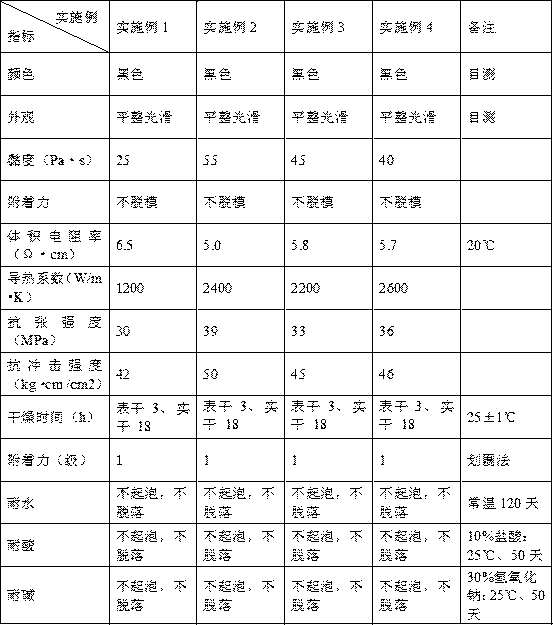

Examples

Embodiment 1

[0047] The graphene conductive and thermally conductive coating described in this embodiment is composed of the following components by weight: 1 part of graphene, 2 parts of carbon nanotubes, 2 parts of sodium silicate, 1 part of paint oil, 1 part of tung oil, and 0.3 part of maleic anhydride , 3 parts of dispersant sodium lignosulfonate, 1 part of acrylic resin, 0.05 part of cobalt drier, 1 part of silane coupling agent, 0.2 part of silicon dioxide, 0.2 part of compound auxiliary ethylene glycol, 0.5 part of lignocellulose , 1.5 parts of zeolite powder, 1 part of thermally conductive metal silver powder, and 40 parts of 60% ethanol.

[0048] A method for preparing a graphene conductive and thermally conductive coating, specifically comprising the following steps:

[0049] (1) Add lacquer oil, tung oil, maleic anhydride and acrylic resin respectively and heat to 65°C, 500r / min and stir evenly for 20min, keep warm for later use;

[0050] (2) Graphene, carbon nanotubes, sodium...

Embodiment 2

[0055] The graphene conductive and thermally conductive paint described in this embodiment is composed of the following components by weight: 10 parts of graphene, 5 parts of carbon nanotubes, 5 parts of sodium silicate, 3 parts of paint oil, 3 parts of tung oil, and 1.5 parts of maleic anhydride , 5 parts of dispersant sodium lauryl sulfate, 3 parts of acrylic resin, 0.5 part of zinc drier, 3 parts of titanate coupling agent, 1 part of silicon dioxide, 1 part of compounding aid 1,2-propanediol, 2 parts of hydroxypropyl methylcellulose, 2 parts of zeolite powder, 8 parts of thermally conductive metal copper powder, 60 parts of 80% ethanol.

[0056] A method for preparing a graphene conductive and thermally conductive coating, specifically comprising the following steps:

[0057] (1) Add lacquer oil, tung oil, maleic anhydride and acrylic resin respectively and heat to 75°C, stir evenly at 1000r / min for 40min, keep warm for later use;

[0058] (2) Graphene, carbon nanotubes, s...

Embodiment 3

[0063] The graphene conductive and thermally conductive paint described in this embodiment is composed of the following components by weight: 5 parts of graphene, 3 parts of carbon nanotubes, 3 parts of sodium silicate, 2 parts of paint oil, 2 parts of tung oil, and 1 part of maleic anhydride , 4 parts of dispersant (sodium lignosulfonate, sodium lauryl sulfate, mass ratio 3:1), 2 parts of acrylic resin, composite drier (cobalt drier, zinc drier, mass ratio 1: 1) 0.2 part, 2 parts of silane coupling agent, 0.6 part of silicon dioxide, 0.6 part of composite auxiliary agent 1,3-propanediol, 1.3 part of sodium carboxymethyl cellulose, 1.8 part of zeolite powder, 4 parts of thermally conductive metal aluminum powder, 50 parts of 70% ethanol.

[0064] A method for preparing a graphene conductive and thermally conductive coating, specifically comprising the following steps:

[0065] (1) Add lacquer oil, tung oil, maleic anhydride and acrylic resin respectively and heat to 70°C, 800...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com