Preparation method of multi-layered wet gradient shell fabric

A gradient and fabric technology, applied in the field of textiles, can solve the problems of high moisture content in the outer layer, low moisture content in the inner layer, reverse osmosis into the fabric, etc., achieve good moisture conductivity, improve comfort, and improve air permeability and moisture permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

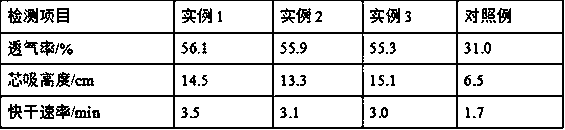

Examples

example 1

[0026] Take 50g of polypropylene filaments, 40g of acrylic filaments, and 5g of spandex staple fibers, mix them evenly, and send them to the opener for opening. After combing through a carding machine, lay the web. 60g / m 2 , to obtain the inner layer moisture-absorbing net, take 50g bamboo fiber and 40g fine denier polyester filament, respectively send them to the opening machine to open, and after carding, take the bamboo fiber as the weft thread and the fine denier polyester filament as the warp thread Laying the net, controlling the surface density of the fiber net to be 50g / m 2 , to obtain a moisture-conducting fiber web, take 40g of triangular cross-section polyester fiber, 50g of cross-section polyester fiber, respectively sent to the opening machine to open, and after carding through the carding machine, take the triangular cross-section polyester fiber as the weft, and take the cross-section polyester fiber as the weft. The polyester fiber is warp laid, and the surfac...

example 2

[0028] Take 55g of polypropylene filaments, 45g of acrylic filaments, and 5g of spandex staple fibers, mix them evenly, and send them to the opener for opening. After combing through a carding machine, lay the web. 80g / m 2 , to obtain the inner layer moisture-absorbing net, take 55g bamboo fiber and 45g fine denier polyester filament, send them into the opening machine to open respectively, and after combing through the carding machine, take the bamboo fiber as the weft thread and the fine denier polyester filament as the warp thread Laying the net, controlling the surface density of the fiber net to be 60g / m 2 , to obtain a moisture-conducting fiber web, take 45g triangular cross-section polyester fiber, 55g cross-section polyester fiber, and send them into the opening machine to open respectively, and after carding, take the triangular cross-section polyester fiber as the weft, and take the cross-section polyester fiber as the weft. The polyester fiber is warp laid, and the...

example 3

[0030] Take 60g of polypropylene filaments, 50g of acrylic filaments, and 6g of spandex staple fibers, mix them evenly, and send them to the opener for opening. After combing through a carding machine, lay the web. 100g / m 2 , to obtain the inner layer moisture-absorbing net, take 60g bamboo fiber and 50g fine denier polyester filament, respectively send them into the opening machine to open, and after carding, take the bamboo fiber as the weft thread and the fine denier polyester filament as the warp thread Laying the net, controlling the surface density of the fiber net to be 70g / m 2 , to obtain a moisture-conducting fiber web, take 50g of triangular cross-section polyester fiber, 60g of cross-section polyester fiber, respectively sent to the opening machine to open, and after carding through the carding machine, take the triangular cross-section polyester fiber as the weft, and the cross-section polyester fiber as the weft. The polyester fiber is warp laid, and the density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com