Preparation method of surface layer material of cotton sanitary product

A hygienic product and surface material technology, applied in the field of hygienic materials, can solve problems such as poor antibacterial properties and poor air permeability, and achieve the effects of improving air permeability, comfort, and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

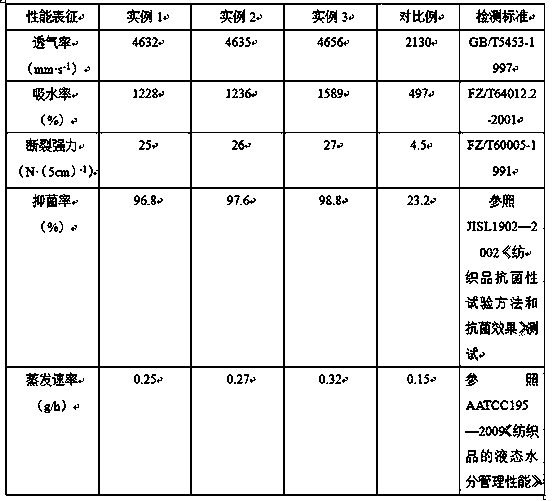

Examples

example 1

[0025] Add 10g of chitosan into 1000g of 2% acetic acid solution, stir at 300r / min for 20min, heat to 30°C, then add 100g of cotton fiber, continue stirring for 3h, take out the cotton fiber, and wash the cotton fiber with deionized water 2 First, to obtain modified cotton fibers, take 1g of tea polyphenols, add 1L of deionized water, stir at 300r / min for 20min, then heat to 35°C, and impregnate the modified cotton fibers for 3h, take out the cotton fibers and wash them with deionized water 3 times, then transferred to the drying oven, dried to constant weight at 105°C, to obtain antibacterial cotton fiber, take 50g antibacterial cotton fiber, 40g ultra-fine denier acrylic fiber, 5g spandex, mix by multi-layer tiling , send the mixed ingredients into the opener for opening, carding through the carding machine and laying the net, control the number of laying layers to 2 layers, and the surface density of the fiber web is 80g / m 2 , to obtain the antibacterial and moisture-conduc...

example 2

[0027] Add 15g chitosan to 1500g mass fraction of 2% acetic acid solution, stir at 350r / min for 25min, then heat to 33°C, then add 150g cotton fiber, continue stirring for 4h, take out the cotton fiber, wash the cotton fiber with deionized water 2 First, to obtain modified cotton fibers, take 1.5g tea polyphenols, add 1.5L deionized water, stir at 350r / min for 25min, then heat to 37°C, and impregnate the modified cotton fibers for 4h, take out the cotton fibers and use deionized water Washed with water for 4 times, then transferred to a drying oven, and dried to constant weight at 107°C to obtain antibacterial cotton fiber. Take 55g of antibacterial cotton fiber, 45g of ultra-fine denier acrylic fiber, 5.5g of spandex, and lay them by multi-layer Mix the ingredients, send the mixed ingredients into the opener to open, carding through the carding machine and laying the web, control the number of laying layers to 2 layers, and the surface density of the fiber web is 100g / m 2 , t...

example 3

[0029]Add 20g of chitosan to 2000g of 2% acetic acid solution, stir at 400r / min for 30min, heat to 35°C, then add 200g of cotton fiber, continue stirring for 5h, take out the cotton fiber, and wash the cotton fiber with deionized water 3 To obtain modified cotton fibers, take 2g of tea polyphenols, add them into 2L of deionized water, stir at 400r / min for 30min, then heat to 40°C, and impregnate the modified cotton fibers for 5h, take out the cotton fibers and wash them with deionized water 5 times, then transferred to the drying oven, dried to constant weight at 110°C, to obtain antibacterial cotton fiber, take 60g antibacterial cotton fiber, 50g ultra-fine denier acrylic fiber, 6g spandex, mix by multi-layer tiling , send the mixed ingredients into the opener for opening, carding through the carding machine and laying the web, control the number of laying layers to 3 layers, and the surface density of the fiber web is 120g / m 2 , to obtain the antibacterial and moisture-condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com