One-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and processing method thereof

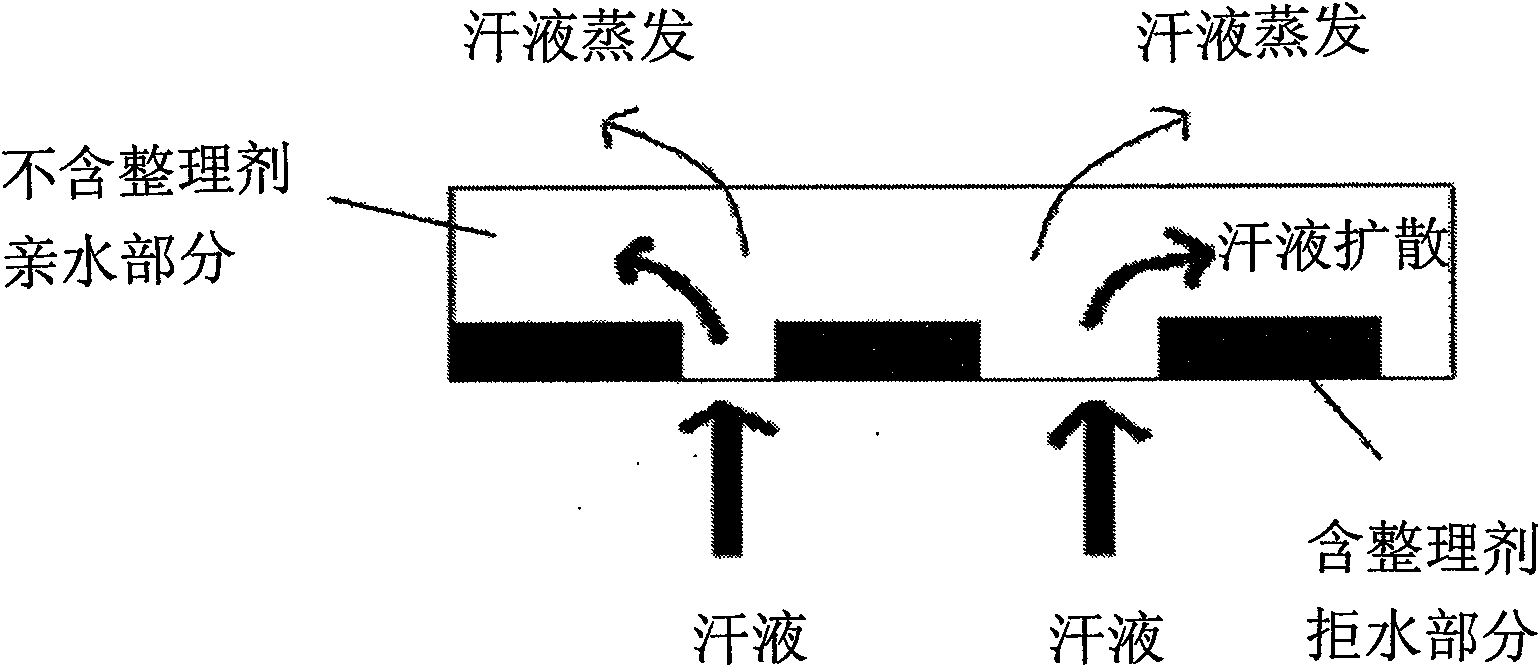

A unidirectional wet-conducting, cashmere technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve problems such as the one-way wet-conducting function is not very ideal, the complete hydrophilic structure of the outer layer of the fabric cannot be fully realized, and the fabric is heavy and so on. , to achieve the effect of good unidirectional wet guide and keep dry performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Fabric: 10% cashmere, 60% Mondale fiber, 30% wool, knitted fabric (specification: 95 # )

[0046] Liquid supply method on one side: printing method

[0047] Opening ratio of the screen: 60%, that is, the reverse side (inner layer, inner side) of the printed fabric has a water-repellent area of 60%.

[0048] The area of each hole in the screen: 4mm 2

[0049] Printing water repellent paste composition:

[0050] Water and oil repellent finishing agent 120g

[0051] Thickener 18g

[0052] Water added to 1000g

[0053] Printing depth: about 1 / 3 of the thickness of the fabric

[0054] Finishing process:

[0055] Fabric pre-washing—→preparation of printing paste or finishing agent—→printing or single-sided liquid supply—→drying (105°C*5min)—→shrinkage—→softening treatment—→drying (85°C*10min)—→ Ironing.

[0056] Washing process:

[0057] Milling agent 4%

[0058] Temperature 50°C

[0059] time 2min

[0060] Bath ratio 1:40

[0061] dehydration

[0062] Sof...

Embodiment 2

[0072] Fabric: 100% cashmere, knit (gauge: 95 # )

[0073] Liquid supply method on one side: printing method

[0074] Opening ratio of the screen: 50%, that is, the reverse side (inner layer, inner side) of the printed fabric has a 50% water-repellent area.

[0075] The area of each hole in the screen: 4mm 2

[0076] Printing water repellent paste composition:

[0077] Water and oil repellent finishing agent 100g

[0078] Thickener 14g

[0079] Water added to 1000g

[0080] Printing depth: about 1 / 3 of the thickness of the fabric

[0081] Finishing process:

[0082] Fabric hydrophilic finishing pretreatment—→preparation of printing paste or finishing agent—→printing or single-sided liquid supply—→drying (105℃*5min)—→washing shrinkage—→softening treatment—→drying (85℃* 10min)—→ Ironing.

[0083] Hydrophilic finishing pretreatment:

[0084] Moisture Wicking Finish HSD 4% owf

[0085] Acetic acid adjust pH=5.5~6.0

[0086] Temperature 50°C

[0087] Time 20min

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com