Preparation method of bionic composite structural knitted fabric

A biomimetic composite structure, knitted fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problem of single function of structure, and achieve the improvement of diffusion evaporation rate, absorption and ventilation performance improvement, and increase diffusion area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a knitted fabric with a biomimetic composite structure, the steps of which are:

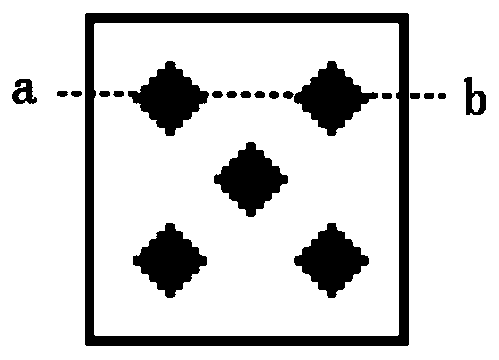

[0036] (1) Design the organizational structure of the knitted fabric: the area of the main area is four times the sum of the areas of the local areas, and the percentage of the area of each local area in the sum of the area of the local areas is 20%; the main area is a single-sided structure, scattered in Multiple local areas in the main area are double-sided structures; each local area is diamond-shaped, specifically as figure 1 As shown, the white area is the main area, and the black area is the local area;

[0037] (2) Knitting: Select a circle-moving rib computerized jacquard circular machine with a machine number of 18 needles, a tube diameter of 34 inches, and a number of 54 (including 36 loops forming loops and 18 loop transfer loops), and a total needle count of 3840. The needle is a latch needle, the number of needles is 1920, the lower needle is a tr...

Embodiment 2

[0056] A method for preparing a knitted fabric with a biomimetic composite structure, the steps of which are basically the same as in Example 1, except that the knitted fabric is obtained without the hydrophilic and hydrophobic finishing in step (3), and the performance test results of the knitted fabric: moisture absorption speed The dry performance is shown in Table 1, and the air and moisture permeability performance is shown in Table 3.

[0057] Comparing Example 1 with Example 2, it can be seen that the moisture absorption and quick-drying performance of Example 2 is lower than that of Example 1. This is because the inner layer of the single-sided structure, the inner layer of the double-sided structure, The outer layers of the single-sided structure and the double-sided structure are finished differently, forming a hydrophilic-hydrophobic gradient on the surface of the fabric, which is conducive to the collection of liquid in the inner layer of the fabric, that is, moving...

Embodiment 3

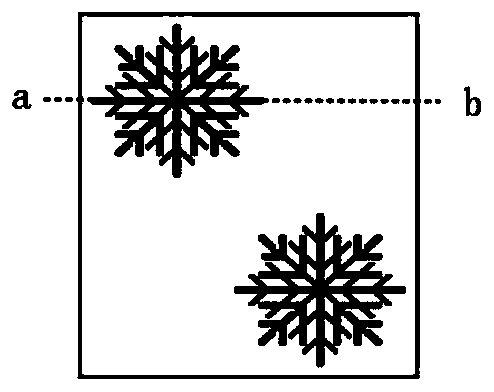

[0063] A method for preparing a knitted fabric with a bionic composite structure, the steps of which are basically the same as in Example 1, except that the shape of the local area is snowflake-shaped, and the area of the main area is 2.9 times the sum of the areas of the local areas. The area of the area accounts for 50% of the sum of the areas of the local areas, such as figure 2 As shown, the white area is the main area, and the black area is the local area; the knitting process is basically the same as that of Example 1, except that in step (2.2), when the upper needle and the lower needle are knitted at the same time, the tuck of the lower needle The number of times is 1; in the performance test results of the knitted fabric: the moisture absorption and quick-drying properties are shown in Table 1, and the air and moisture permeability properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com