Harmless treatment method and harmless treatment device for industrial petroleum wastes

A technology of harmless treatment and petroleum industry, applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of unsuitable on-site treatment, large occupation area, large water consumption, etc., to achieve The treatment product is completely harmless, low energy consumption and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

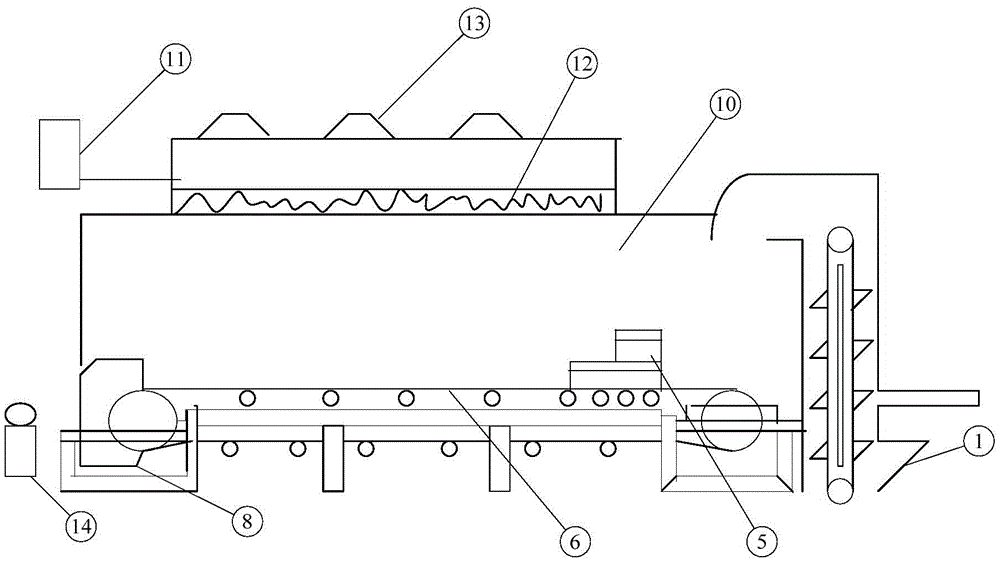

[0074] This embodiment provides a device for harmless treatment of petroleum industrial waste, wherein the device includes

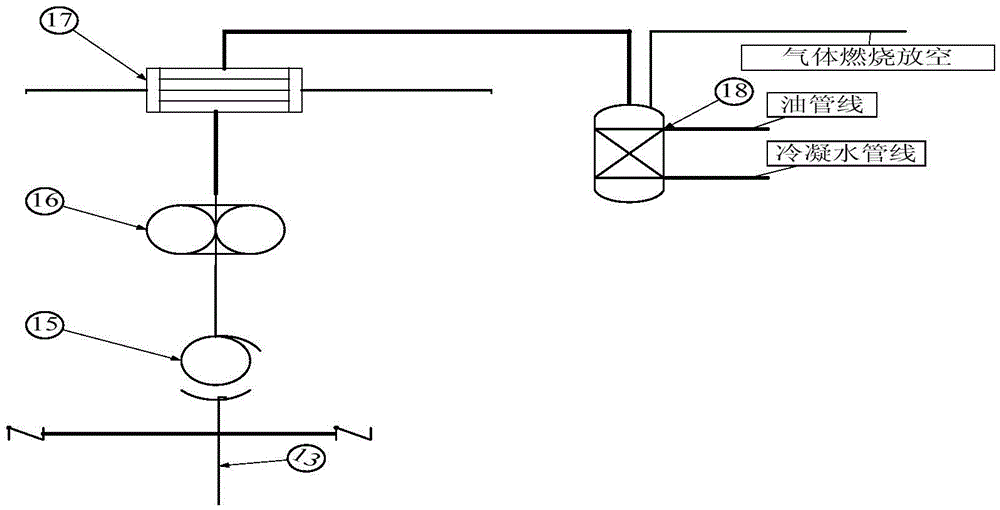

[0075] Bucket elevator 1, feeding hopper 5, microwave device, conveying device with conveyor belt 6, solid waste storage tank 14, filtering device 15, gas compressing device 16, condensing device 17 and oil-gas-water three-phase separation device 18;

[0076] The microwave device includes a microwave heating box 10, a microwave conduit 12 and a microwave source 11; the microwave conduit 12 and the microwave source 11 are located on the upper surface of the microwave heating box 10, and the microwave source 11 is located at the microwave conduit 12 and the microwave heating box Between 10; the microwave device is provided with an exhaust port 13 for discharging the gas generated during the pyrolysis process of petroleum industrial waste out of the microwave heating box;

[0077] The bucket elevator 1 is a bucket elevator 1 for adding oil industry waste to...

Embodiment 2

[0088] This embodiment provides a method for harmless treatment of petroleum industrial waste, which is realized by using the device for harmless treatment of petroleum industrial waste provided in Example 1 above, which includes the following steps:

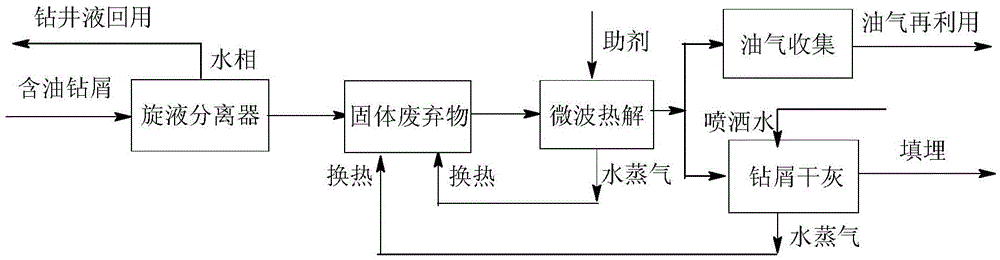

[0089] During the development of onshore oilfields, the mud pump is 0.25m 3 The / h feed rate is transported into the two-stage series solid control separator, and the clear liquid from the second stage is collected and used as the liquid in the oilfield development process to continue to be recycled and reused. Collect the sludge solid waste separated by the secondary solid control separator. The sludge solid waste contains 27% water, 21% oil and 52% solid content. Add 5% petroleum coke additive, stir well to form the sludge solid mixture; use the bucket elevator 1 to add the sludge solid mixture into the hopper 5, then spread the sludge solid mixture evenly on the conveyor belt 6 along with the movement of the conveyor belt 6, ...

Embodiment 3

[0093] This embodiment provides a method for harmless treatment of petroleum industrial waste, which is realized by using the device for harmless treatment of petroleum industrial waste provided in Example 1 above, which includes the following steps:

[0094] During the drilling and development of offshore oilfields, mud pumps are used to pump 0.5m 3 / h feed rate is transported into the three-stage solid control separator in series, and the clear liquid from the third stage is collected and used as the liquid in the oilfield development process to continue to be recycled and reused. Collect the concentrated oily sludge solid waste separated by the three-stage solid control separator. The concentrated oily sludge solid waste contains 24% water, 12% oil, and 64% drilling cuttings. Add 15% petroleum coke additive, stir to form the sludge solid mixture; use the bucket elevator 1 to add the sludge solid mixture into the hopper 5, and then spread the sludge solid mixture evenly on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com