Device for enhancing heat dissipation performance of freezer compressor shell

A refrigerator compressor, heat dissipation technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of uneven temperature distribution, high temperature, lower compressor temperature, etc. The effect of simple heat dissipation structure scheme and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

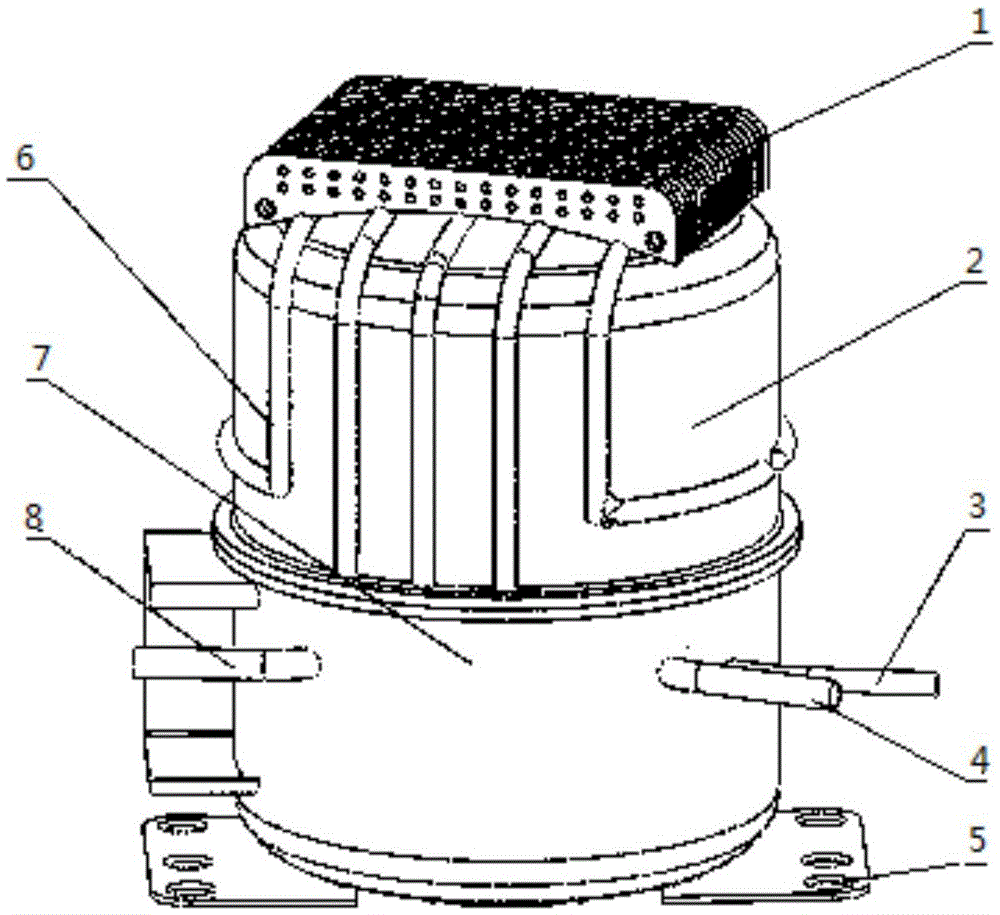

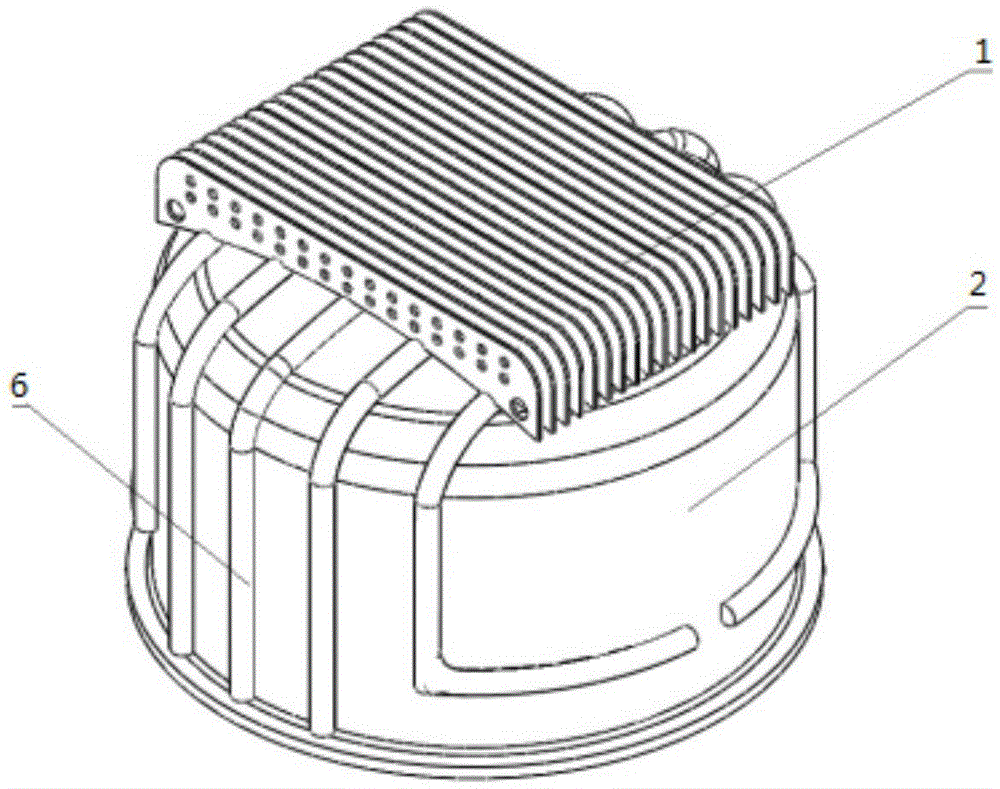

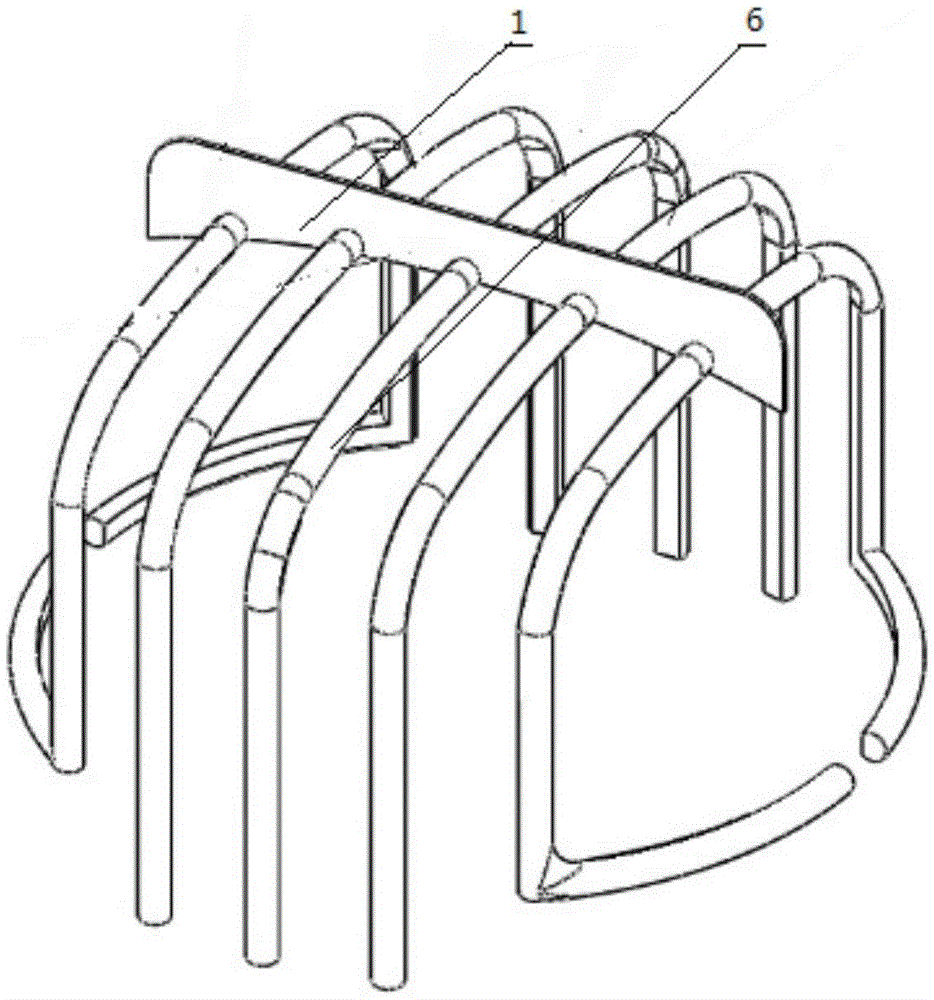

[0040] Such as figure 1 As shown in the figure, a device for enhancing the heat dissipation performance of a refrigerator compressor housing mainly includes a compressor upper housing 2, a compressor lower housing 7, a suction connecting pipe 4, an exhaust connecting pipe 3, a heat pipe 6 and a cooling fin 1 The compressor upper casing 2 is in the shape of a cylindrical cover, and the top end is a small arc arc surface; the lower compressor casing 7 is also in the shape of a cylindrical cover, and the lower end is designed with a base, and there are 4 fixing bolt holes 5 on the base; The body 2 and the compressor lower casing 7 are connected to each other to form a closed space, and assembled into the outer casing of the compressor to protect the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com