Regeneration method of desulphurization, denitration and demercuration combined activated coke and special-purpose device thereof

A desulfurization, denitrification, mercury removal and regeneration device technology, which is applied in the regeneration field of combined desulfurization, denitrification and mercury removal active coke, can solve the problems of temperature rise, poor heat transfer performance, and small thermal conductivity of active coke, so as to reduce dangerous accidents and deal with The effect of improved capacity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

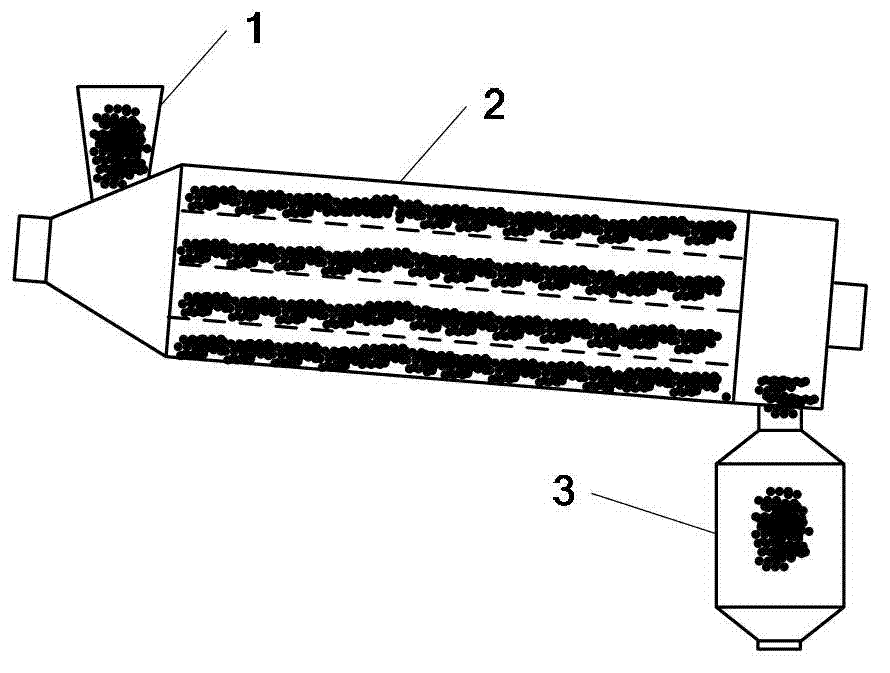

[0038] Example 1. Regeneration device for combined desulfurization, denitrification and demercuration active coke

[0039] Such as figure 1 As shown in Figure 2, the regeneration device for combined desulfurization, denitrification and demercuration active coke provided by the present invention includes a rotary kiln 2 and a material cooler 3; The feed port end of the converter 2 is higher than its discharge port end, which helps active coke move slowly from its feed port end to the discharge port end along with the rotation of the rotary kiln; the feed port end of the rotary furnace 2 There is a feed bin 1 on the top, and the feed bin 1 is connected with the ring cavity of the rotary furnace 2, and the active coke to be regenerated enters the ring cavity of the rotary furnace 2 from the feed bin for regeneration; the material cooler 3 is connected with the rotary furnace The ring cavity of 2 is connected, and the connection is located near the discharge port of rotary furnac...

Embodiment 2

[0040] Embodiment 2, regeneration of active coke

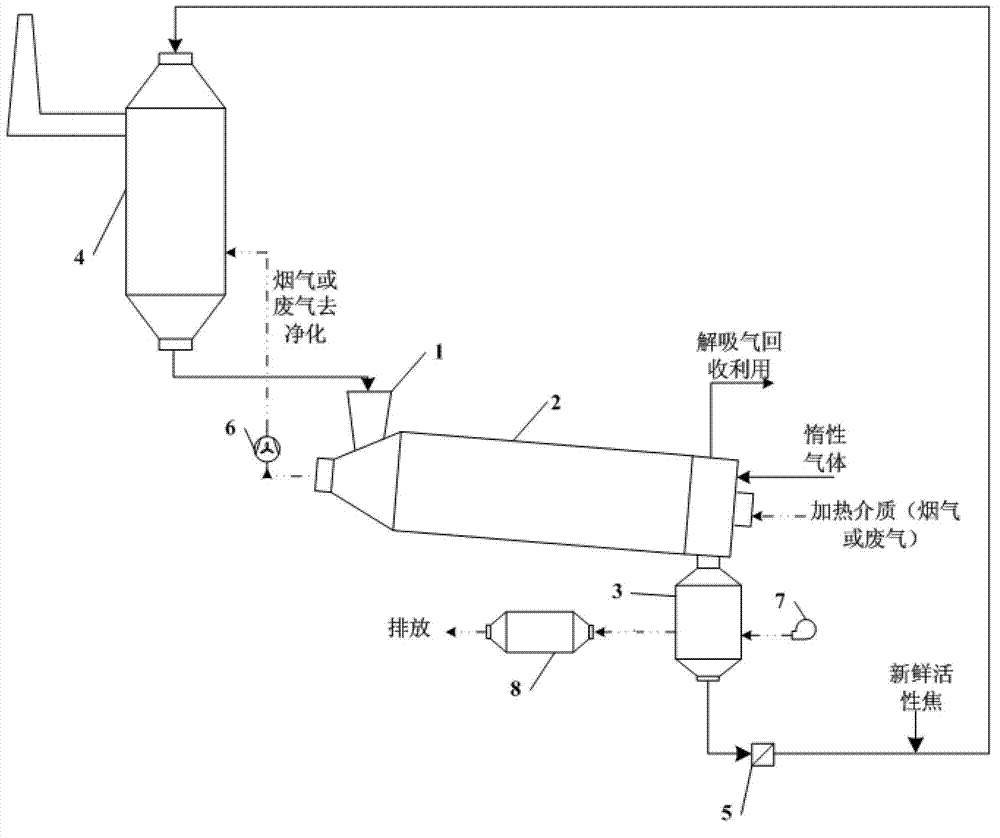

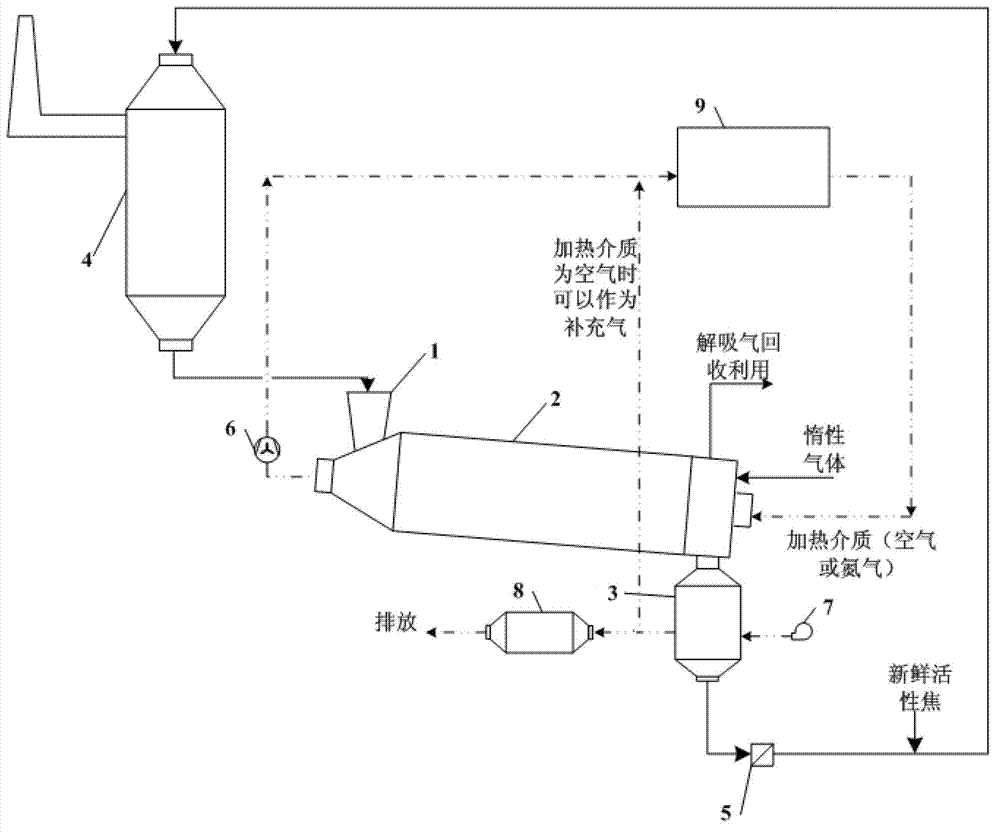

[0041] Such as Figure 2aAs shown, using hot flue gas or hot waste gas as the heating medium, the regeneration device provided above is used to regenerate the active coke. The specific process is: in the flue gas purification reactor 4, the active coke desulfurizes and purifies the flue gas; The bottom of the flue gas purification reactor 4 is discharged into the feed bin 1, and then into the ring chamber of the rotary furnace 2; at the same time, under the action of the induced draft fan 6, the heating medium (hot flue gas or hot waste gas, the temperature is 450°C) from the outlet end of the rotary furnace 2 into the furnace body of the rotary furnace 2; the active coke in the rotary furnace 2 slowly moves to the outlet end with the rotation of the rotary furnace 2, and then in the rotary furnace 2 , the active coke and the heating medium move towards each other and exchange heat, such as image 3 As shown, activated coke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com