Heat dissipation method of LED (light-emitting diode) device and device

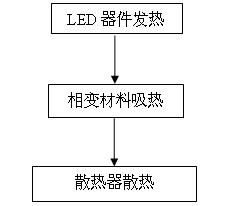

A technology of LED devices and heat dissipation methods, which is applied in lighting devices, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., and can solve problems such as poor heat dissipation effect, high manufacturing cost, and inability to meet the heat dissipation requirements of LED devices. Achieve rapid heat absorption, stable and reliable operation, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

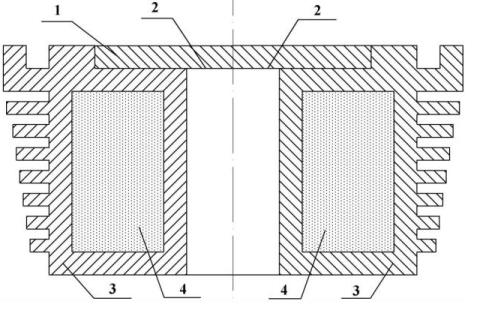

[0028] like figure 2 As shown, this embodiment is suitable for heat dissipation of common LED lighting equipment. The heat dissipation device of the LED device of the present invention comprises a heat dissipation bottom plate 1, a heat conducting sheet 2, and a metal shell 3; the outer surface of the metal shell 3 has annular fins; the annular fins are welded on the metal shell; the heat dissipation bottom plate 1 and the metal shell The body 3 is connected through the heat conducting sheet 2; the metal shell 3 is filled with a composite phase change material 4.

[0029] A composite phase change material of paraffin wax / expanded graphite with a phase change temperature of 52°C is used to fill the metal shell, and the power of the LED lamp is 2W. The heat of the LED lamps is first conducted to the heat dissipation bottom plate, and then the heat dissipation bottom plate transfers the heat to the metal shell. While the outer surface of the metal shell is dissipating heat, the...

Embodiment 2

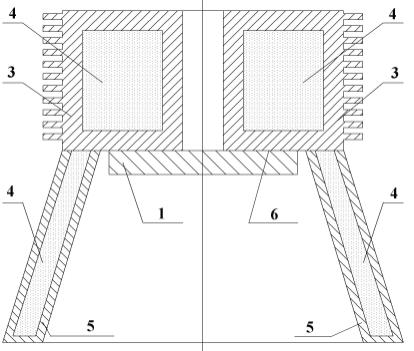

[0031] like image 3 As shown, this embodiment is suitable for heat dissipation of LED lighting equipment with lampshade. The heat dissipation device of the LED device of the present invention comprises a heat dissipation bottom plate 1, a heat conducting sheet 2, a metal shell 3 and a metal cover 5, the outer surface of the metal shell 3 has strip-shaped fins, and the fins and the metal shell are integrally formed at one time; The heat dissipation bottom plate 1 is connected to the metal shell 3 through the heat pipe 6, the condensation end of the heat pipe 6 is connected to the metal shell 3, and the evaporation end of the heat pipe is connected to the heat dissipation bottom plate 1; the metal shell and the metal housing are respectively filled with composite phase change materials 5.

[0032] The metal casing is filled with a paraffin / expanded graphite composite phase change material with a phase transition temperature of 52°C, and the metal housing is filled with a paraff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com