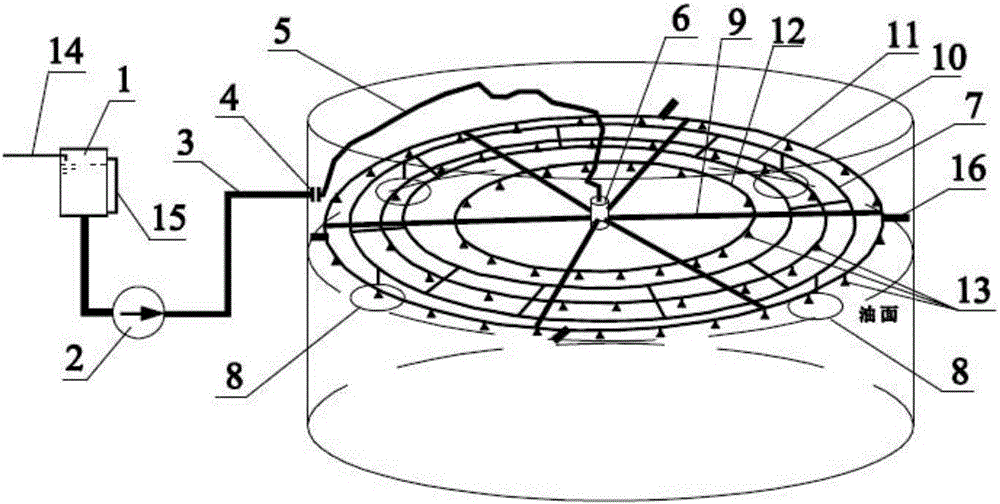

Annular water mist fire extinguishing system of oil storage tank

A fire-extinguishing system and water mist technology, applied in fire rescue and other directions, can solve the problems of re-exposed oil surface, slow fire-extinguishing speed, and large economic losses, and achieve the effects of increased evaporation rate, fast fire-extinguishing speed and less water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

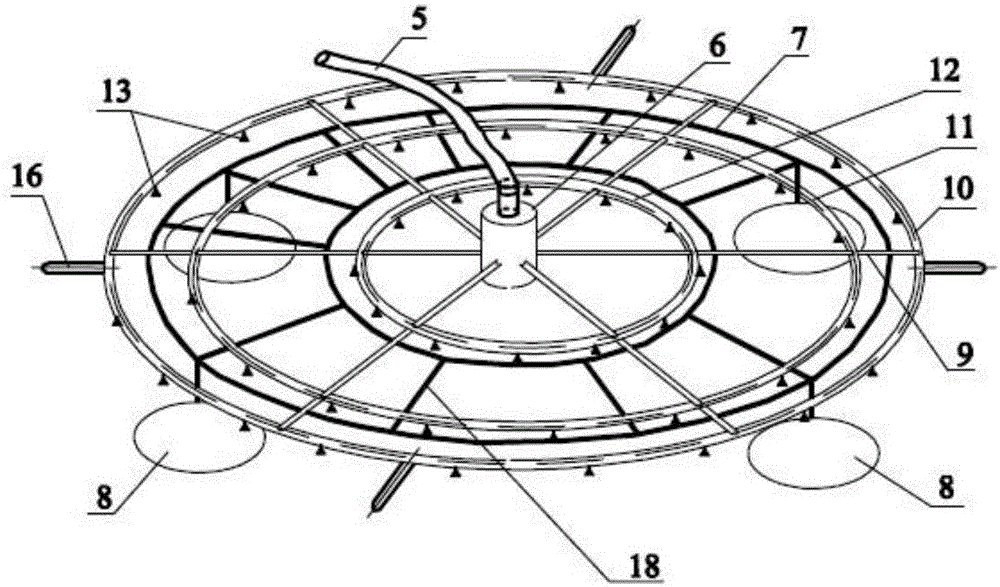

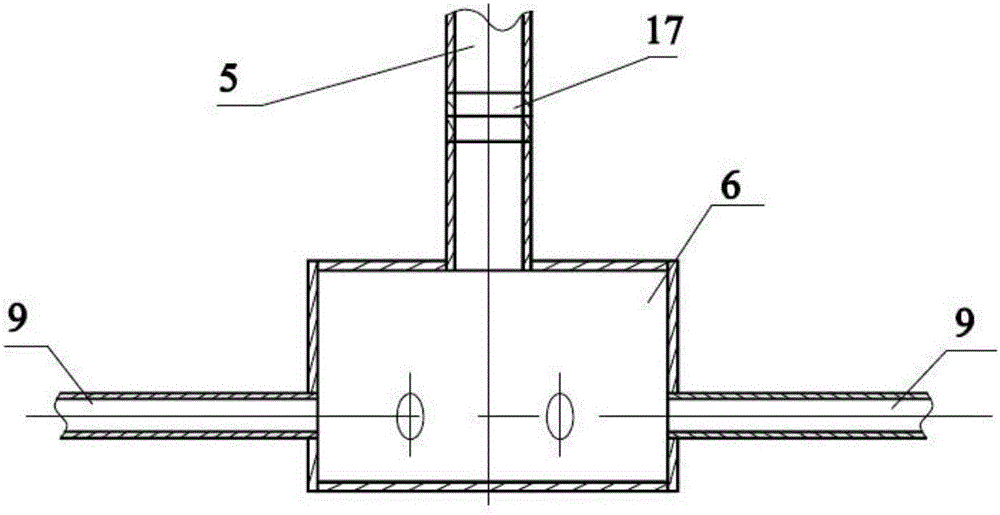

[0026] Embodiment: Referring to the accompanying drawings, the ring-shaped water mist fire extinguishing system of the oil storage tank in this embodiment is provided with a metal bracket 7 suspended on the oil surface in the oil storage tank, and a fine water mist is fixedly arranged on the metal bracket 7 Spraying device, the water mist spraying device communicates with the high-pressure water supply device outside the oil storage tank through pipelines; wherein, the metal bracket 7 consists of 2-3 aluminum alloy rings that form concentric circles, and are connected between the aluminum alloy rings. There are reinforcing ribs 18 between them, and a supporting floating ball 8 is provided at the bottom of the aluminum alloy ring / rib; eight reinforcing ribs 18 are arranged, and the eight reinforcing ribs are radially and equally distributed in the circumferential direction of the aluminum alloy ring; The supporting floating ball 8 is set to four, and the four floating balls are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com