Metal net base corrugate pipe type phase change heat storage device

A phase-change heat storage and bellows-type technology, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of small heat exchange area, poor heat transfer efficiency, and low heat storage capacity. Achieve the effects of large heat exchange area, improved heat storage capacity, and fast heat absorption and release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

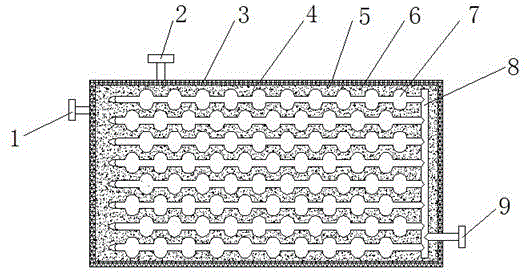

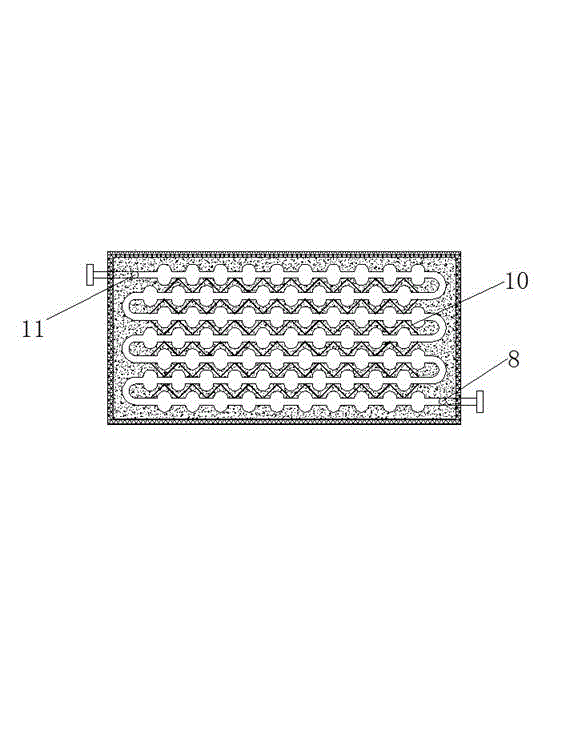

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , 2 As shown, a metal mesh-based bellows type phase change heat storage device includes a shell 3 and a heat storage box 5. The heat storage box 5 is divided into multiple layers, and consists of a shell, a heat exchange tube 7, and a fluid distribution tube 11. Composed of fluid collection pipes 8, the corrugated pipes of each layer communicate with the fluid collection pipes 8 through fluid distribution pipes 11, and the corrugated pipes between layers form a tight staggered arrangement in the heat storage box 5, in the same layer The nodes and troughs of two adjacent rows of corrugated pipes correspond to closely staggered rows. At the same time, metal wires 10 are wound between two adjacent rows of corrugated pipes to form a mesh structure to enhance heat transfer. Other vacant places in the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com