Device and method for reducing oxidation degree of adsorbed solvent

A technology of degree of oxidation and adsorption of solvents, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as damage, accelerated oxidation and decomposition reactions, poor thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

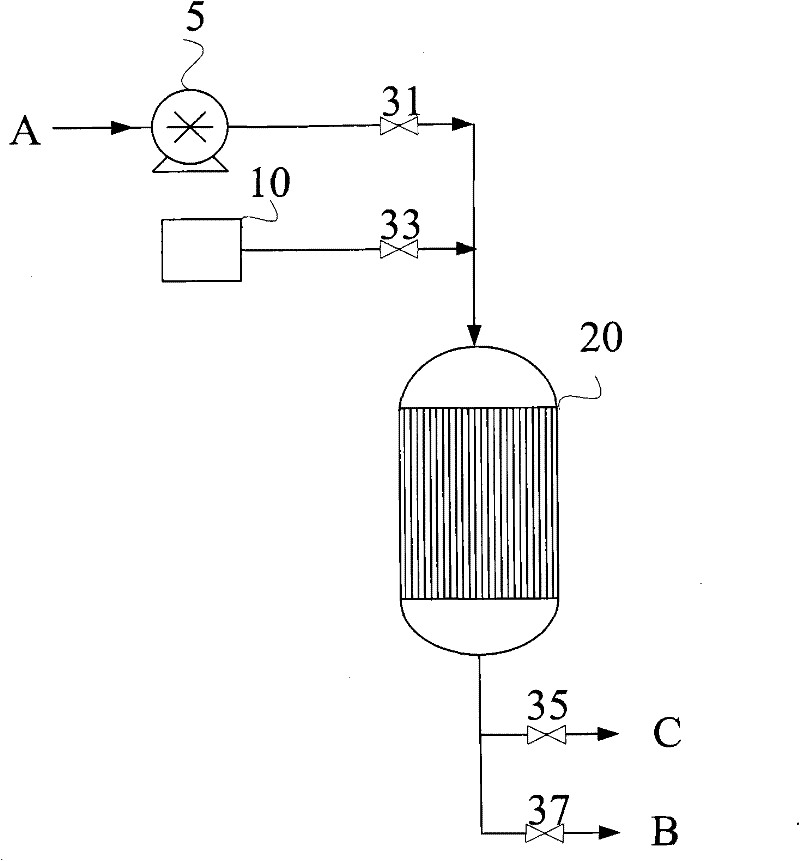

[0047] See figure 2 , which is a specific embodiment of a device for reducing the degree of oxidation of the adsorbed solvent in the present invention, which includes a fan 5 , a steam generating unit 10 , an inert gas generating unit and an activated carbon adsorption and desorption unit 20 .

[0048]The operation of the present invention to purify the organic waste gas to be treated is as follows. The plurality of valves 31, 33, 35, 37 and 39 in the device are opened or closed as required. First, the organic waste gas is pumped from the air inlet A through the fan 5, and then The valve 31 enters the activated carbon adsorption-desorption unit 20, and the adsorption procedure is carried out in the activated carbon adsorption-desorption unit 20, that is, the organic matter (comprising ketone solvent) in the organic waste gas is the The activated carbon is absorbed, and the clean air after purification flows out through the air outlet B through the valve 37; when the adsorptio...

Embodiment 2

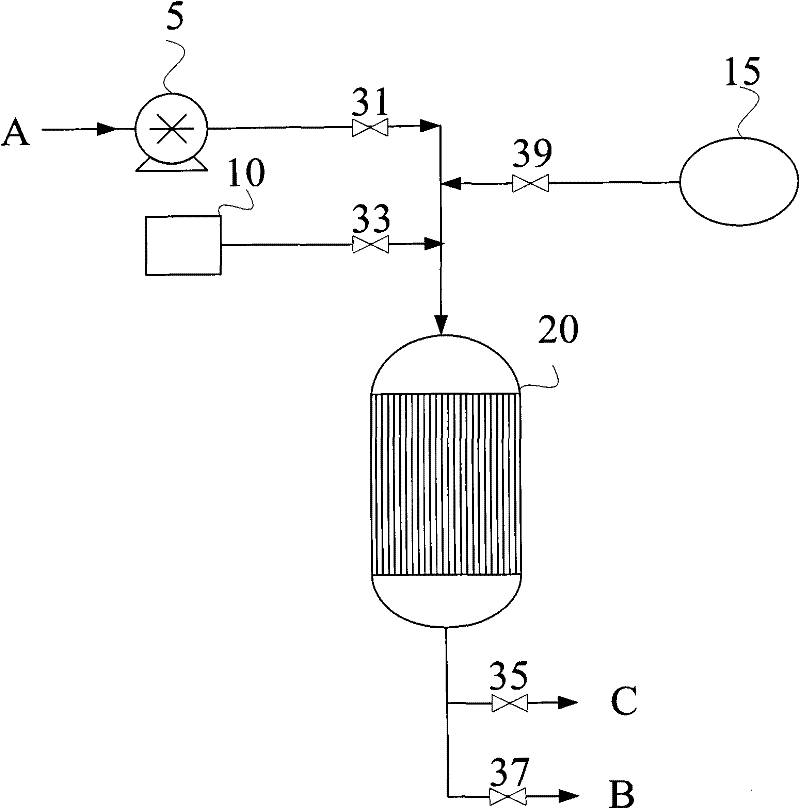

[0051] See image 3 , which is another specific embodiment of a device for reducing the degree of oxidation of the adsorbed solvent in the present invention, which includes a fan 5, a steam generating unit 10, an inert gas generating unit and two activated carbon adsorption and desorption units 20, 22 (And these activated carbon adsorption and desorption units are connected in series).

[0052] The operation of the present invention to purify the organic waste gas to be treated is as follows. The plurality of valves 31, 33, 35, 37 and 39 in the device are opened or closed as required. First, the organic waste gas is pumped from the air inlet A through the fan 5, and then The valve 31 enters these activated carbon adsorption and desorption units 20, 22, and the adsorption procedure is carried out in these activated carbon adsorption and desorption units 20, 22, that is, the organic substances (comprising ketone solvents) in the organic waste gas are absorbed and desorbed by the...

Embodiment 3

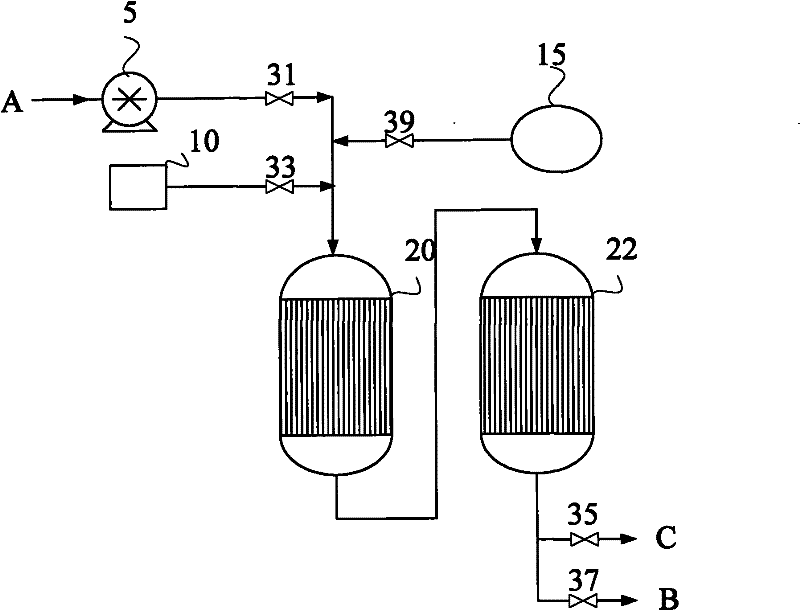

[0055] See Figure 4 , which is another specific embodiment of a device for reducing the degree of oxidation of the adsorbed solvent in the present invention, which includes a fan 5, a steam generating unit 10, an inert gas generating unit and two activated carbon adsorption and desorption units 20, 22 (And these activated carbon adsorption and desorption units are connected in parallel).

[0056] The operation of the present invention to purify the organic waste gas to be treated is as follows. The plurality of valves 31, 32, 33, 34, 35, 36, 37, 38, 39 and 40 in the device are opened or closed as required. First, the organic waste gas is removed from the The air inlet A is pumped through the fan 5, and enters the activated carbon adsorption-desorption units 20, 22 through the valves 31, 32, and the adsorption process is carried out in these activated carbon adsorption-desorption units 20, 22, that is, the organic matter in the organic waste gas (comprising ketone solvents) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com