Instant tofu jelly powder and preparation method thereof

A bean curd brain powder and instant food technology, which is applied in the field of food processing, can solve the problems of heavy bean flavor, poor elasticity, and unrefined texture, so as to increase instant solubility and dispersibility, improve texture and elasticity, reduce The effect of small oxidation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

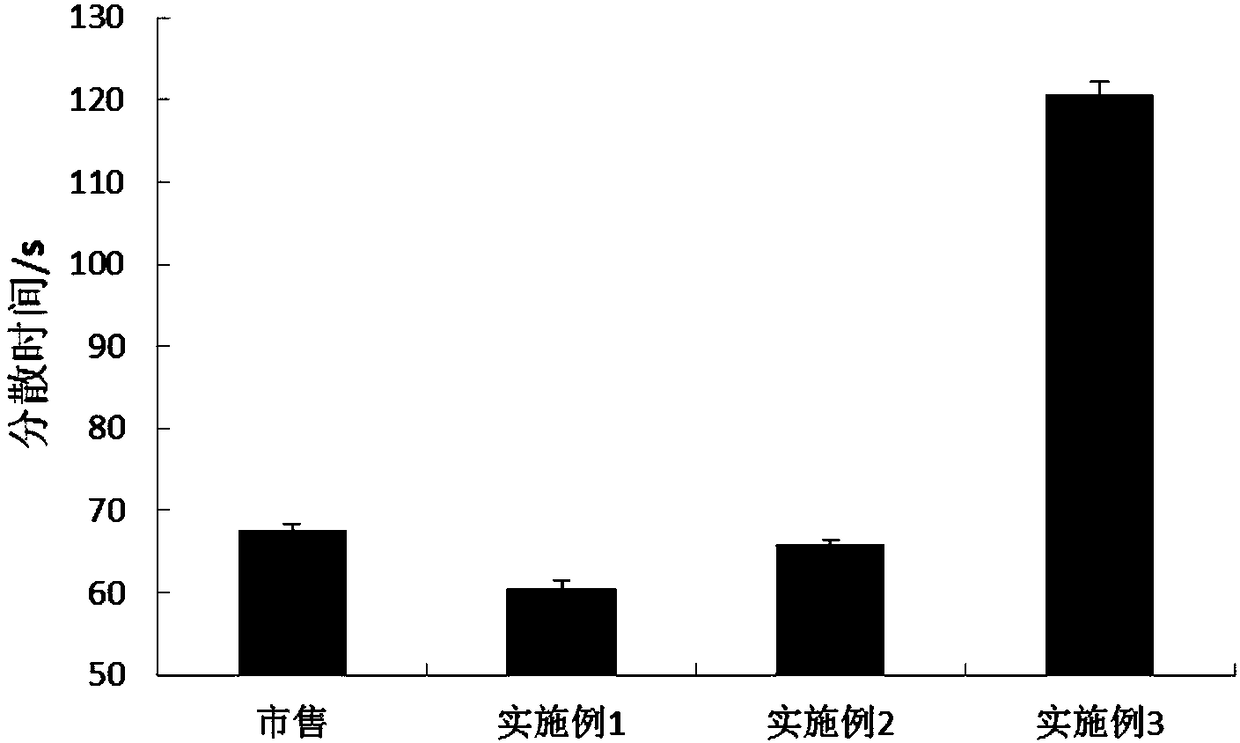

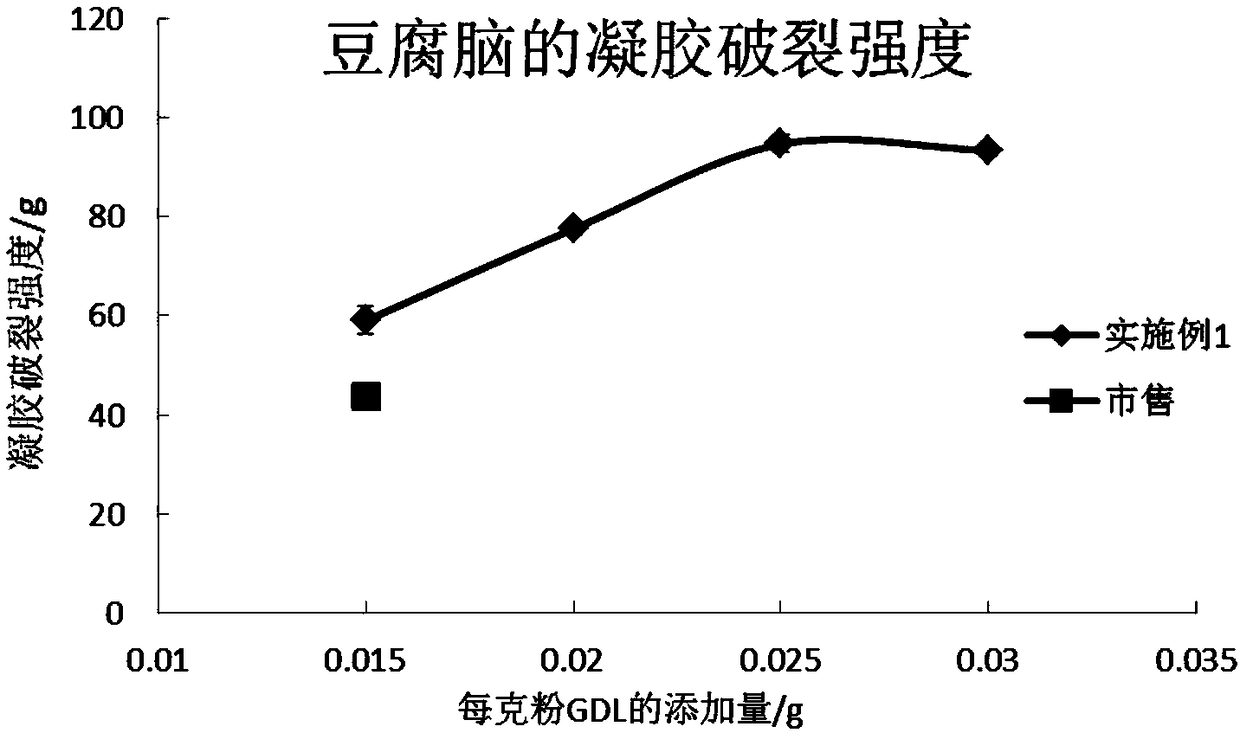

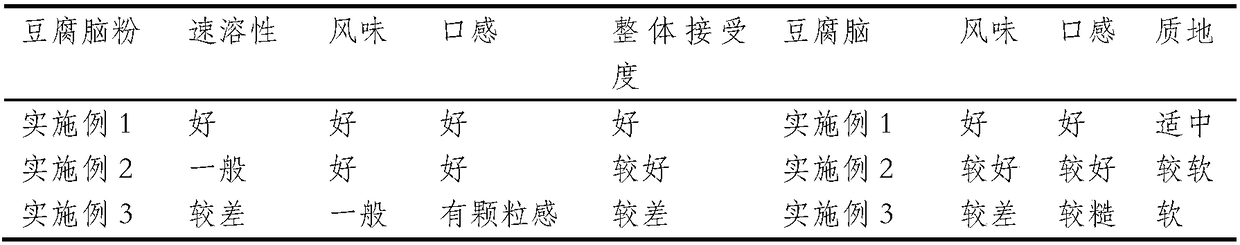

Embodiment 1

[0032] Soybeans are washed and soaked at 25°C for 8 hours, and the soaked soybean raw materials and treated water are transported into the front tank, and the soybean raw materials are continuously fed into the refiner at a constant speed through the solid-phase material quantitative feeder internal treatment, and the solid-liquid separation of the milled paste is carried out in the separator in the plant protein raw material processing device under airtight conditions, and the operating parameters of the milled paste flow controller are set: the refining temperature is 20°C, and the solid phase material is quantitatively The feeding rate of the feeder (converted to dry beans) is 56.90kg / h, and the mass flow rate of the milling outflow is 355kg / h. During the refining process, the pressure gauge readings are all greater than 0.1MPa, and a slurry with a solid content of about 10% is obtained. Set the treated water with a conductivity of 10μs / cm and a dissolved oxygen content of 0...

Embodiment 2

[0038] Soybeans are washed and soaked at 25°C for 8 hours, and the soaked soybeans enter the plant protein raw material processing device for refining. The refining parameters are: the refining temperature is 20°C, and the bean feeding rate of the solid-phase material quantitative feeder (Converted to dry beans) 56.90kg / h, the outflow mass flow rate of grinding paste is 455kg / h, the pressure gauge readings are all greater than 0.1MPa during the grinding process, and soybean milk with a solid content of about 8% is obtained.

[0039] The obtained slurry was subjected to heat treatment. The conditions of the heat treatment were heating temperature 100° C. and time 60 s. After the slurry was heated, it was cooled to room temperature.

[0040] In order to prepare 100kg of mixed material liquid, take 91kg of soybean milk and 9kg of maltose, mix and stir evenly, the unit of stirring speed is r / min, and the range is 50r / min to 200r / min, boil the mixed material to sterilize, and boil t...

Embodiment 3

[0043] Soybeans are washed and soaked at 25°C for 8 hours, and the soaked soybeans enter the plant protein raw material processing device for refining. The refining parameters are: the refining temperature is 20°C, and the bean feeding rate of the solid-phase material quantitative feeder (Converted to dry beans) 56.90kg / h, the mass flow rate of the milling outflow is 555kg / h, the pressure gauge readings are all greater than 0.1MPa during the refining process, and soybean milk with a solid content of about 6% can be obtained.

[0044] The obtained slurry was subjected to heat treatment, and the conditions of the heat treatment were heating temperature 121° C., time 30 s, and the slurry was cooled to room temperature after heating.

[0045] In order to prepare 100kg of mixed material liquid, take 87kg of soybean milk, 5kg of maltose, and 2kg of maltodextrin, mix and stir evenly, the unit of stirring speed is r / min, and its range is 50r / min to 200r / min, and cook the mixed material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com